Modular elements, network, supporting structure, construction and process for obtaining thereof

A technology for supporting structures and components, applied in construction, building materials, building components, etc., can solve the problems of expensive, unsuitable for ceilings, unable to meet suitable supporting structures, etc., and achieve short-term, simple and cost-effective thermal insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

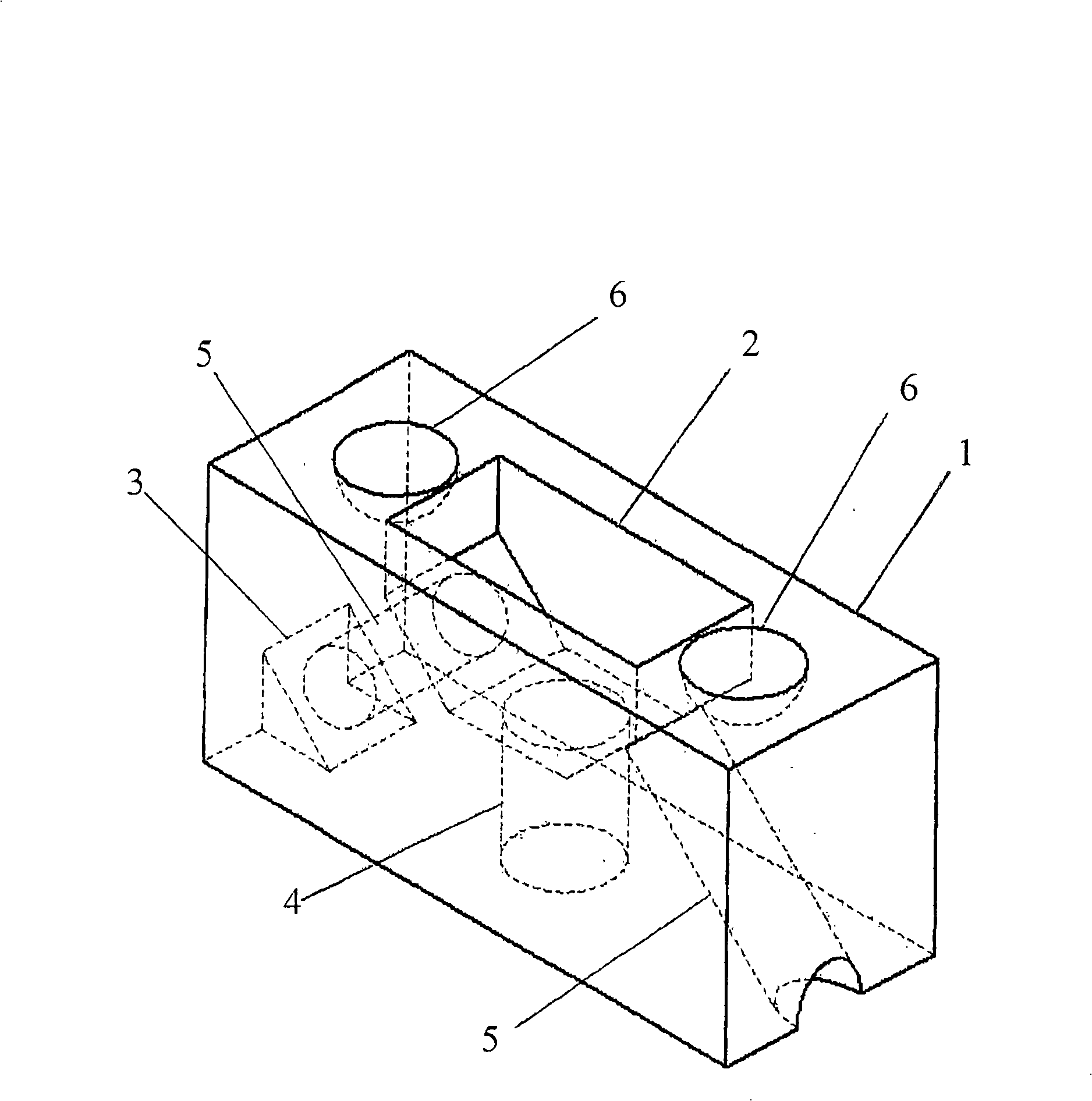

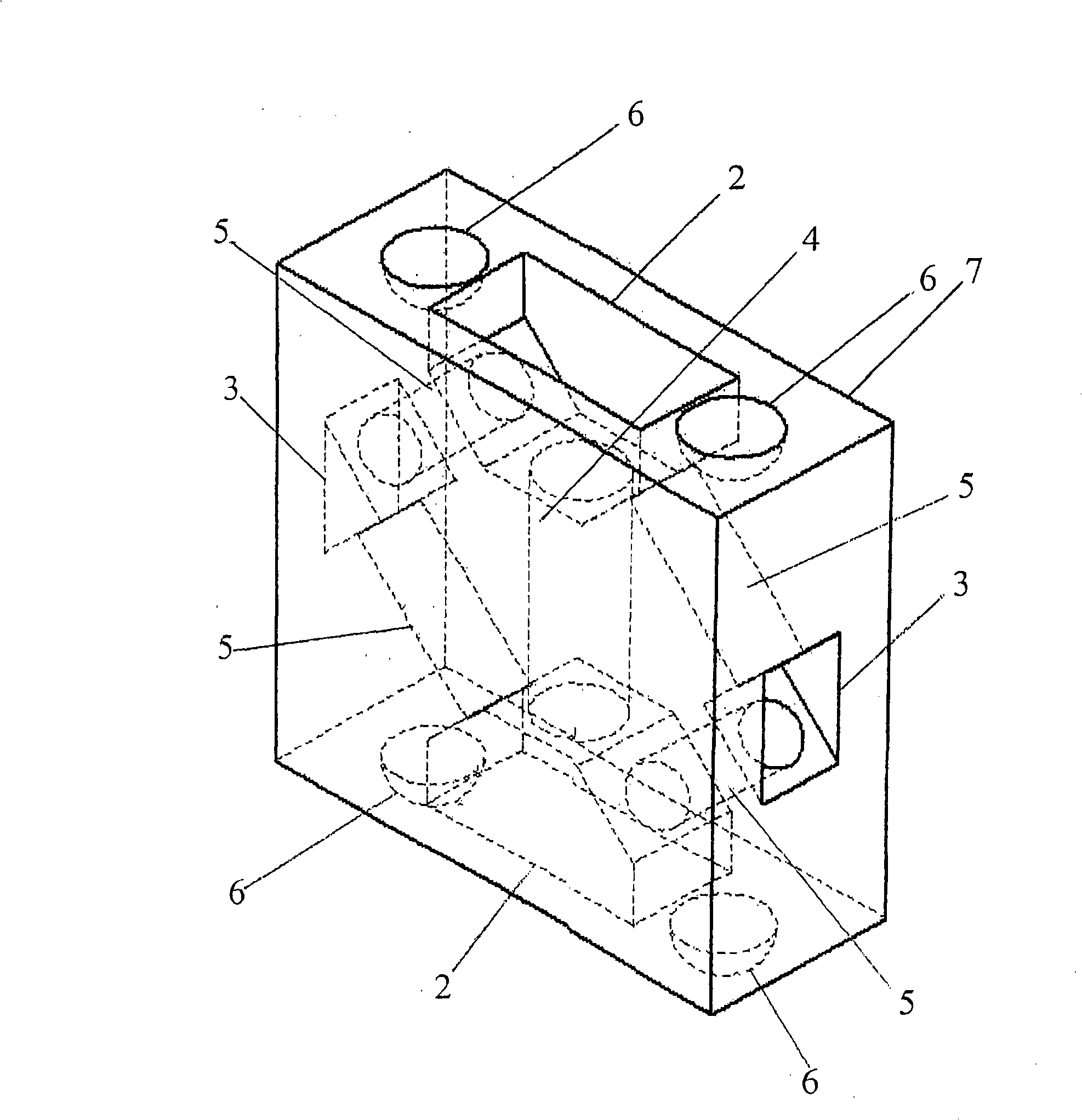

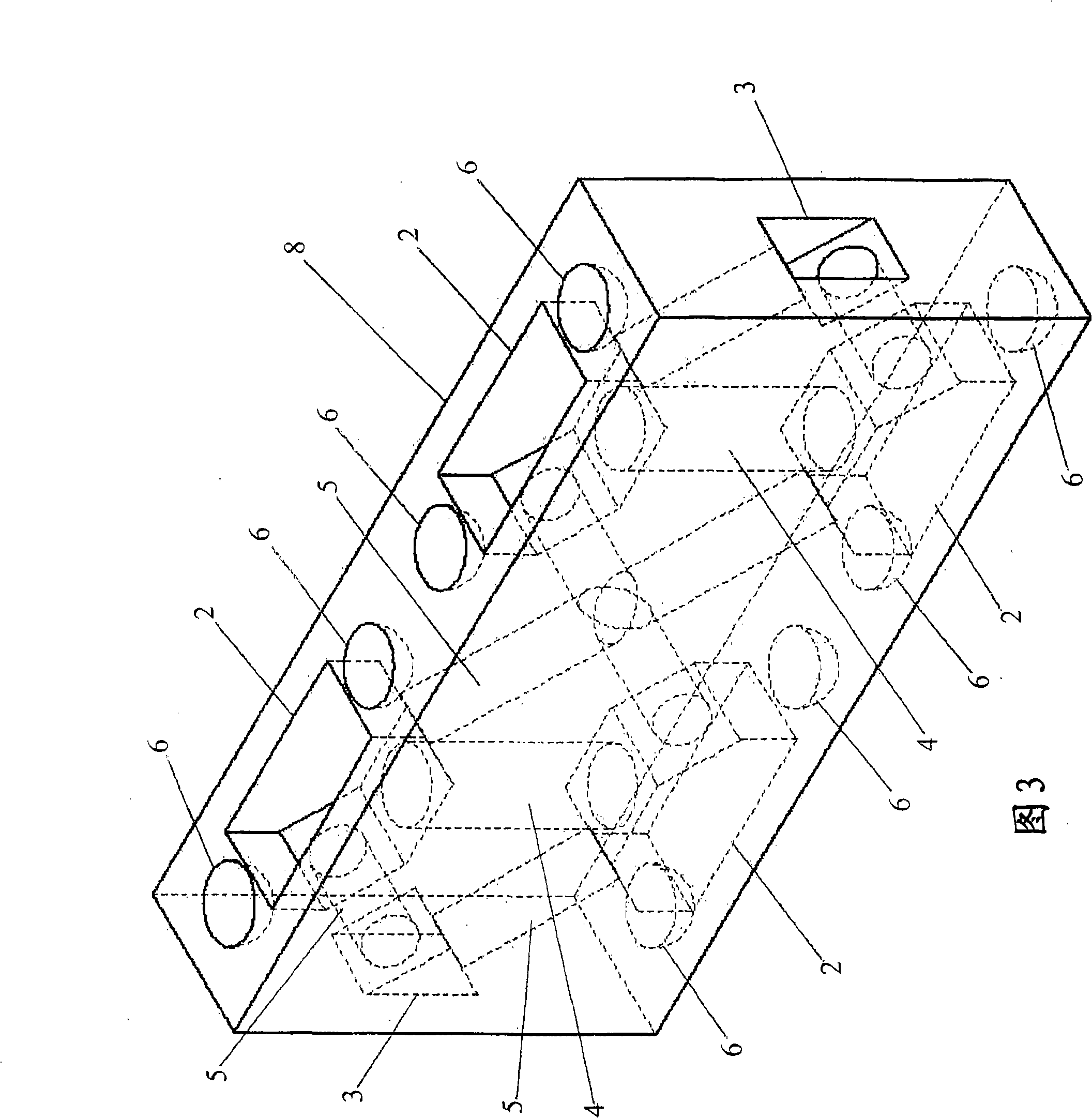

[0037] There are various modular elements for walls ( figure 1 ), modular elements for corners (Fig. 4), modular elements for foundations (Fig. 5), modular elements for ceilings made of fire-resistant polyurethane foam (Fig. 6).

[0038] The modular elements have the following dimensions:

[0039] The modular elements for walls have dimensions 120 / 60 / 30 cm, with vertical channels with a diameter of 16 cm, inclined channels with a diameter of 12 cm and joint elements of 20 cm.

[0040] The modular elements for the corners measure 120 / 60 / 30 cm on one side and 60 / 60 / 30 cm on the other side, with vertical channels with a diameter of 16 cm, inclined channels with a diameter of 12 cm and joint elements of 20 cm.

[0041] The dimensions of the modular elements for the foundation are 120 / 60 / 60 cm, with a vertical channel with a diameter of 20 cm, an inclined channel with a diameter of 14 cm and a joint element with a diameter of 20 cm

[0042] The dimensions of the modular elements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com