Regenerating unit for softening device for washing machine

A regeneration device and softener technology, which is applied to washing devices, other washing machines, ion exchange regeneration, etc., can solve the problems of incomplete siphon discharge of brine, difficulty in restoring the regeneration state, and the influence of softener regeneration function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

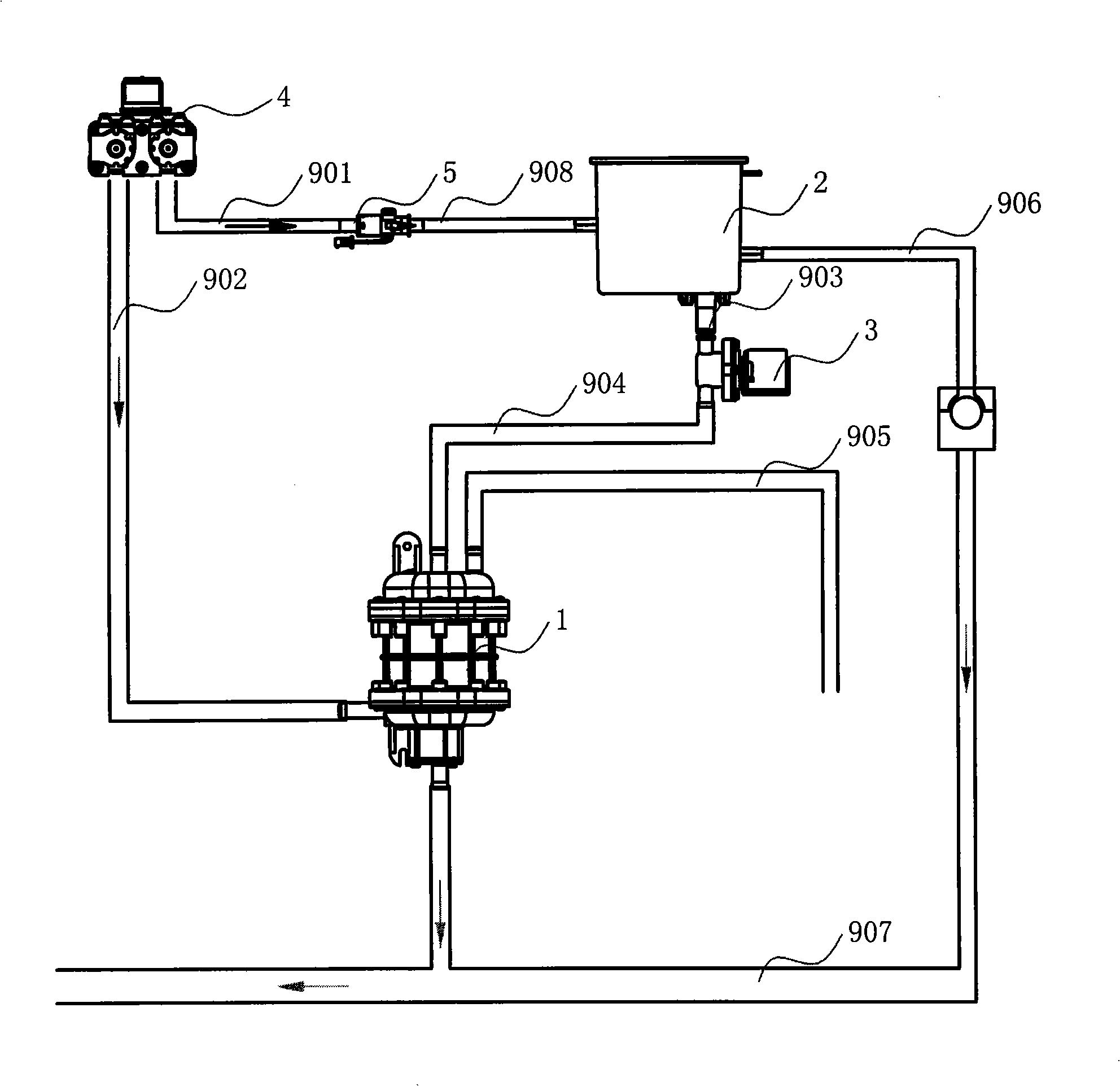

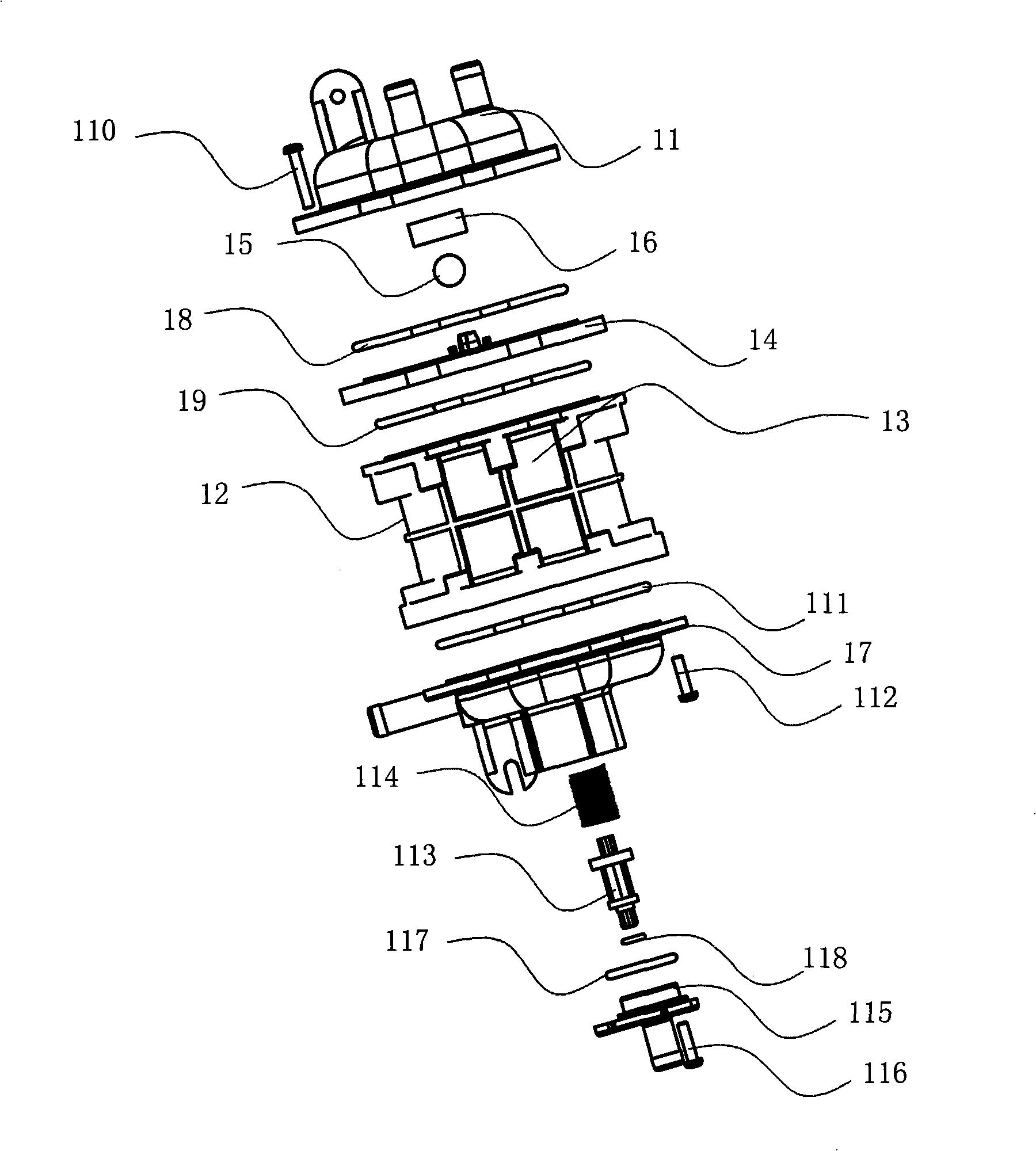

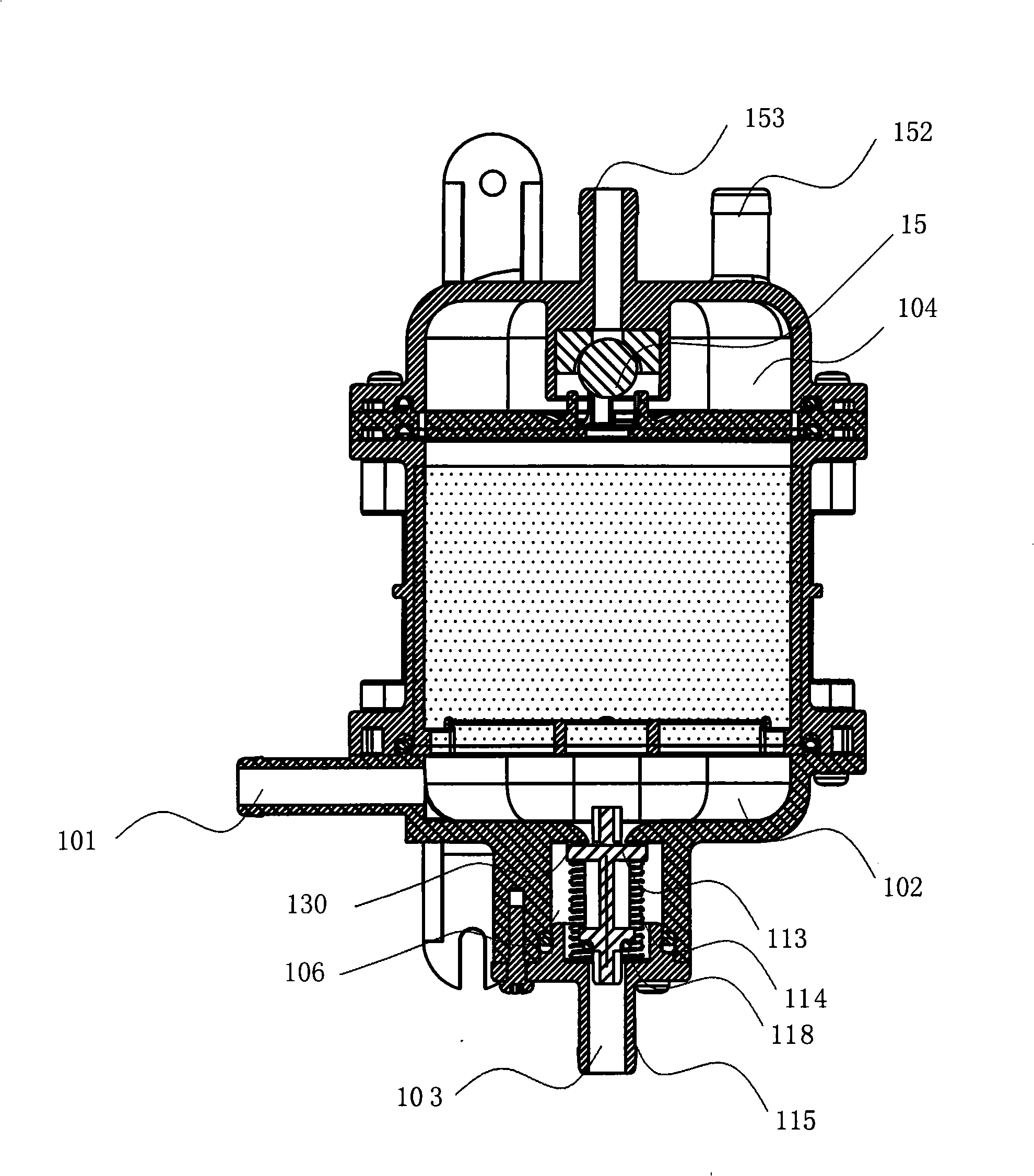

[0041]The regeneration device of the softener for washing machine has a softener 1 and a regeneration fluid switch valve 3 connected through a hose 904. The regeneration fluid switch valve 3 is installed below the regeneration agent dispenser 2, and the softener 1 and the flow sensor 5 are respectively passed through The hose 902 and the hose 901 are connected with an electromagnetic water inlet valve 4; the regenerant dispenser 2 is composed of a regenerant container 22 and a built-in regenerant container 21. One side of the regenerant container 22 is provided with a water inlet 201, and One side is provided with an overflow port 202 located at the water inlet 201, an outlet of the electromagnetic water inlet valve 4 is connected to the water inlet 101 of the softener 1 via a hose 902; the outlet 152 of the softener is output to the washing machine via hose 905 for softening Water, equipped with a control circuit board with a microprocessor CPU and a program to control the water ...

Embodiment 2

[0078] The regeneration device in this example is different from the above example in that there is no flow sensor 5, such as Picture 12 As shown, the control program in the microprocessor is: the electromagnetic water inlet valve is opened for a period of time and then closed for a period of time, so that saturated regenerant liquid is generated in the regenerant dispenser, and the electromagnetic water inlet valve is opened for a period of time to cause the water to enter. The saturated regenerated liquid is diluted, and then the regenerated liquid on-off valve is opened to input the diluted regenerated liquid into the softener. Specifically: the electromagnetic water inlet valve is opened, and the water inlet time timing starts at the same time. After the timing reaches 10 seconds (about 60cc of water), the electromagnetic water inlet valve closes. Then the system waits for 30 minutes to allow the water in the regenerant dispenser to dissolve to saturation. After 30 minutes, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com