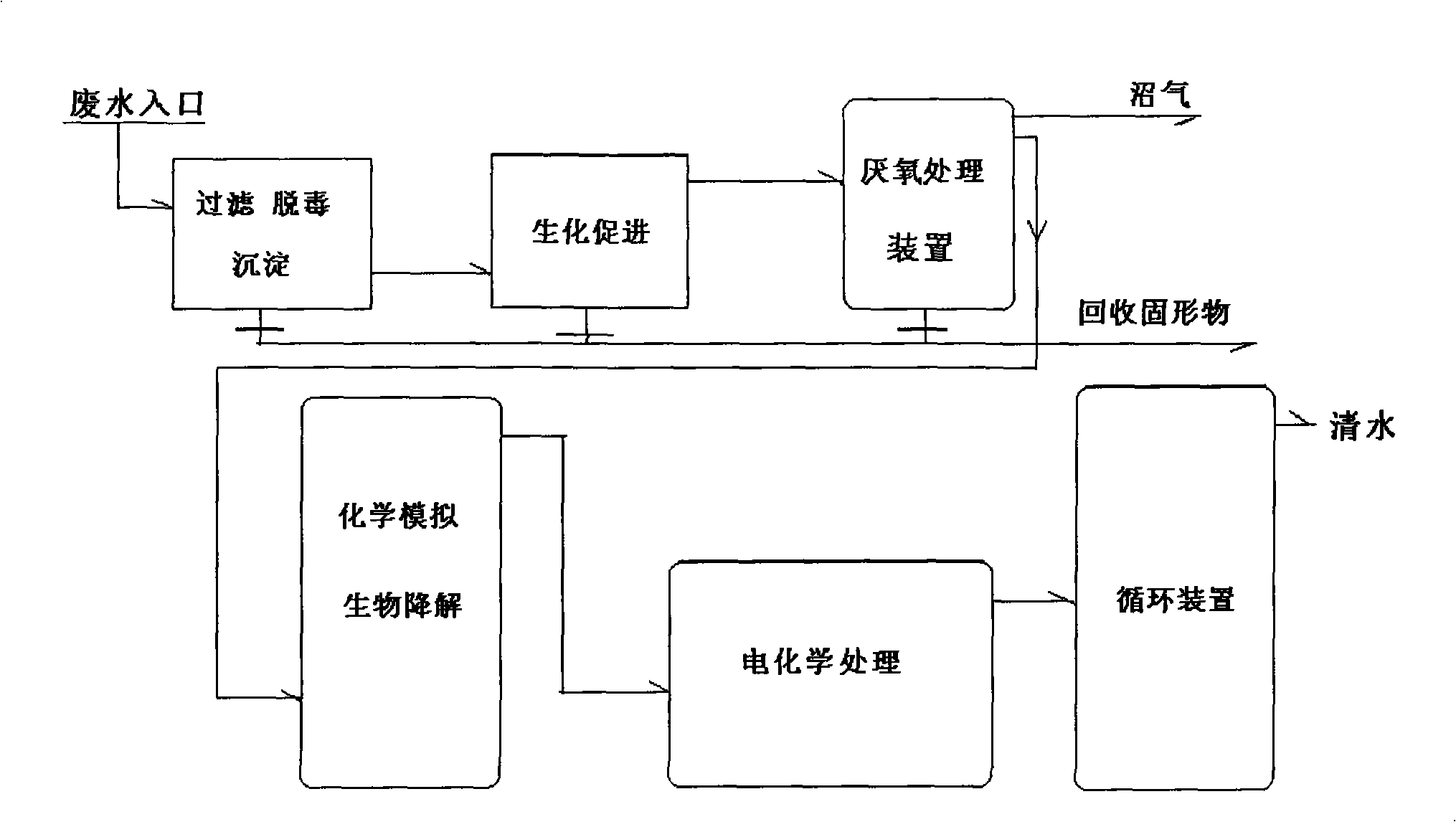

Comprehensive approach for process and cyclic utilization of sewage water

A comprehensive treatment and sewage treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, electrochemical water/sewage treatment, etc. The effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

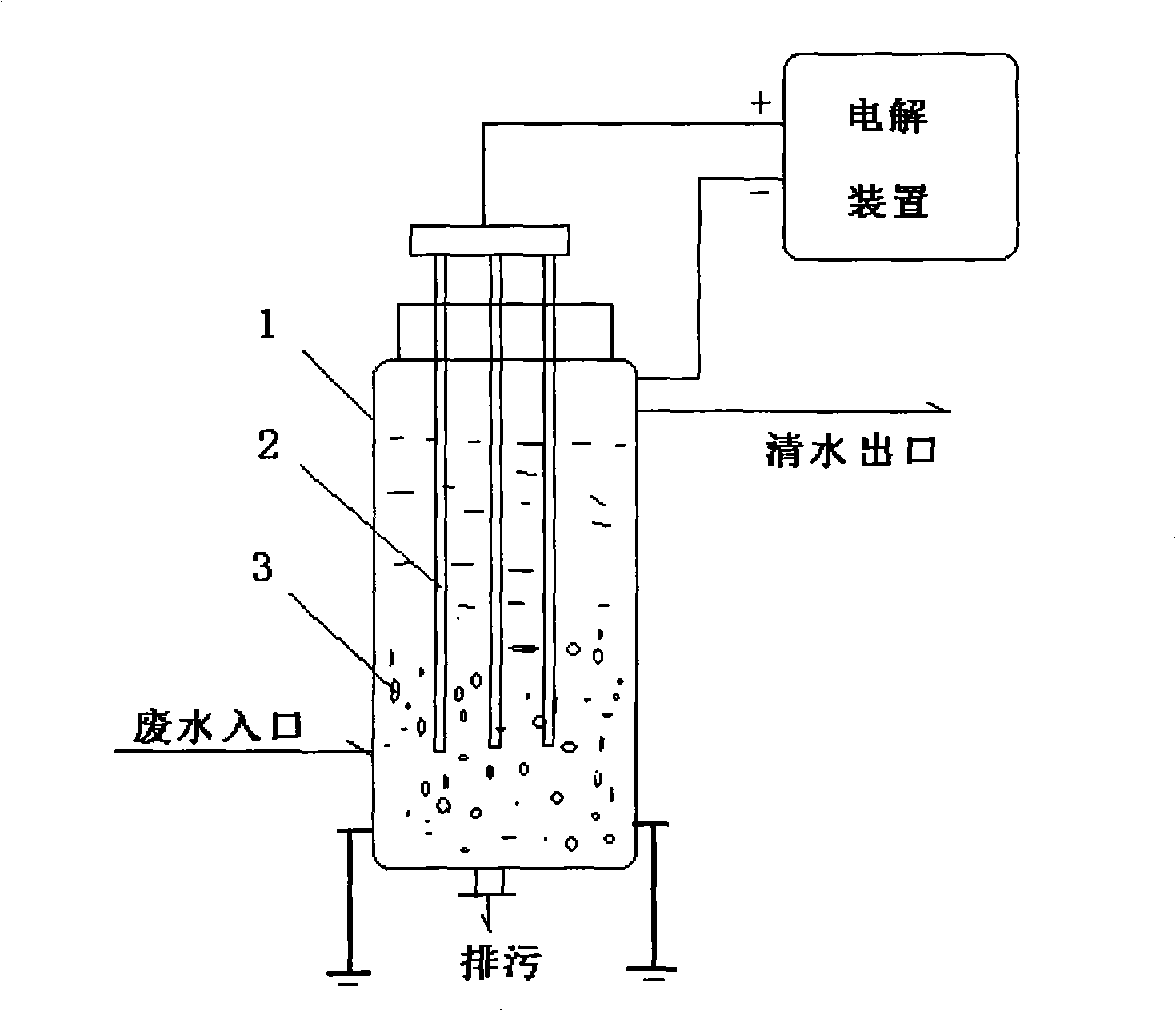

Embodiment 1

[0048] Papermaking black liquor treatment in a factory in Guangxi: Influent COD4000~5000mg / L, first neutralize the black liquor with wastewater from a sulfuric acid plant to neutral, then filter and precipitate the wastewater, the sediment contains fibers and can be recycled after cleaning The pulp tank is connected to the tank with electrode rods, the positive electrode is carbon rod, the negative electrode is metal tank, the voltage is 30-50 volts DC, and the current is 300-500mA. The pretreated wastewater can remove most of the waste water during the biochemical promotion process. Suspended solids that cannot be naturally precipitated are condensed into particles that can be precipitated, and the treated wastewater enters the anaerobic biochemical degradation process. In the biochemical promotion fermentation tank, anaerobic bacteria and 0.01-0.05% ammonium phosphate and ammonium bicarbonate with a mass content of 0.01-0.05% are put in And ferric sulfate (wherein ammonium ph...

Embodiment 2

[0050] The wastewater from a starch factory in a certain factory in Guangxi, the influent COD is 12000-15000 mg / L, the wastewater is filtered and precipitated first, and the sediment contains part of starch and protein, which can be recycled to the pulp pool and passed into the tank equipped with electrode rods. Carbon rod, the negative electrode is a metal tank, the voltage is 40-50 volts DC, and the current is 400-450mA. The pretreated wastewater can condense most of the suspended solids that cannot be naturally precipitated into sedimentable particles during the biochemical promotion process. After the waste water enters the anaerobic biochemical degradation process, in the biochemical promotion fermentation tank, drop into 0.01-0.05% diammonium phosphate and ammonium bicarbonate and ferric sulfate of anaerobic bacteria and mass content (wherein diammonium phosphate accounts for 3 parts by weight, Ammonium bicarbonate accounts for 4 parts, and iron sulfate accounts for 1 par...

Embodiment 3

[0052]Alcohol waste liquid from a sugar factory in Guangxi, influent COD60000-120000mg / L, first heat the waste water to 60-100°C, add lime, adjust to neutral, filter and precipitate, the precipitate can be used as a concrete admixture, It is connected to the tank with electrode rods, the positive electrode is carbon rod, the negative electrode is metal tank, the voltage is 40-50 volts direct current, and the current is 400-450mA. After the treatment, the wastewater enters the anaerobic biochemical degradation process. 0.01-0.05% diammonium phosphate and ammonium bicarbonate and iron sulfate (wherein diammonium phosphate accounts for 3 parts by weight, ammonium bicarbonate accounts for 4 parts, and iron sulfate accounts for 1 part) of anaerobic bacteria and mass content, so The above-mentioned anaerobic bacteria can be obtained from ordinary biogas digesters, generally taken from the bottom mud of well-fermented biogas digesters, adding 2-3 kg of mud per cubic meter of fresh was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com