Automatic multi-way control valve

A multi-way control valve, automatic technology, applied to multi-way valves, valve details, valve devices, etc., to achieve the effect of reducing the volume of the valve body, easy processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

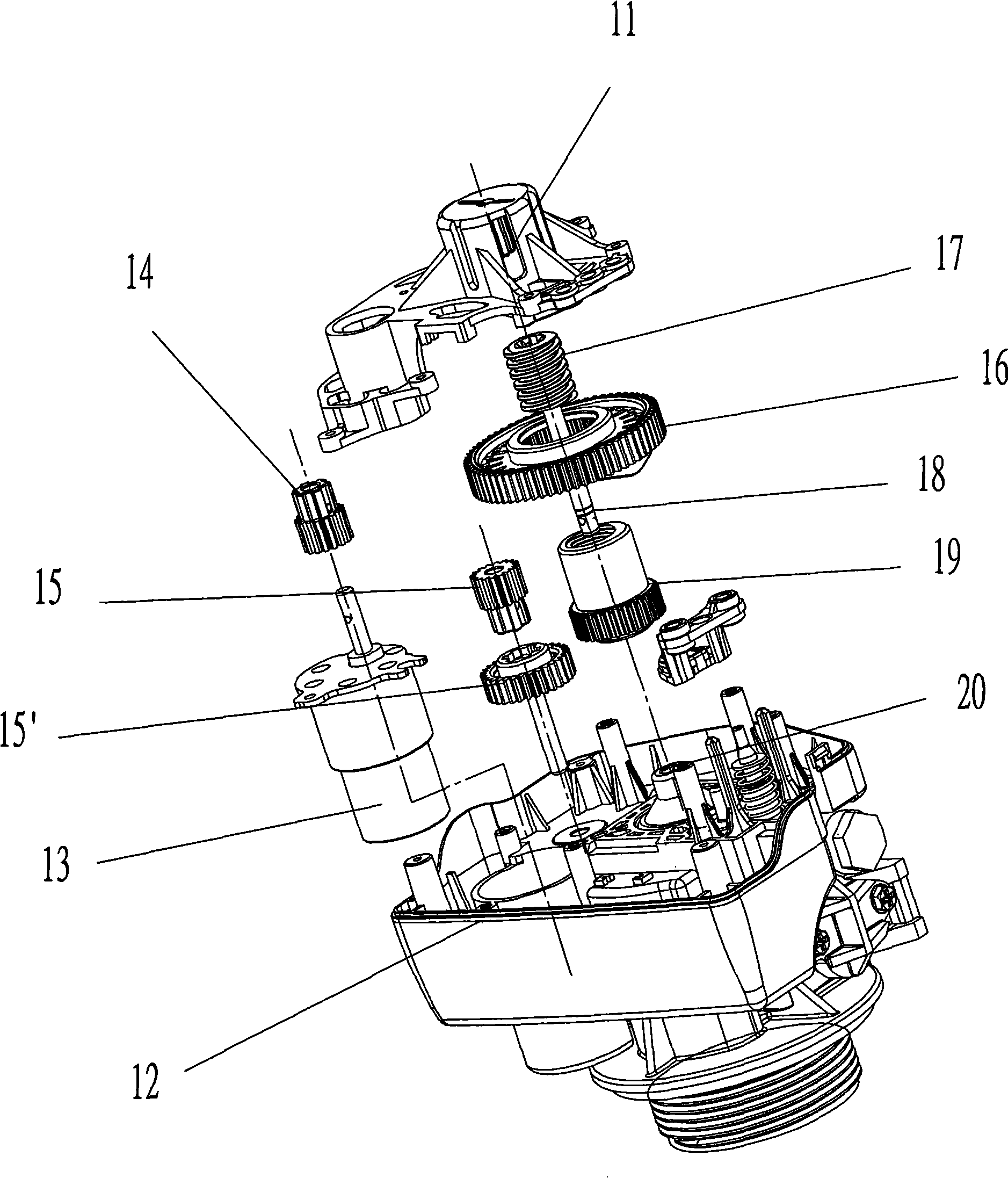

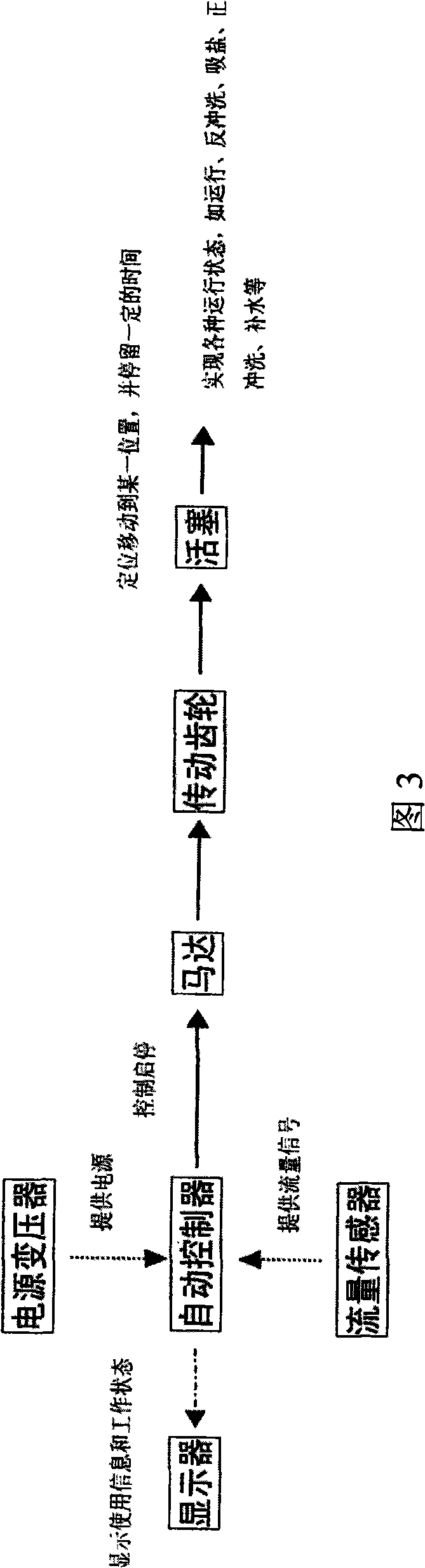

[0022] The following is based on Figure 1 to Figure 5 The preferred embodiments of the present invention are given to facilitate those skilled in the art to understand the structural features and functional features of the present invention, rather than to limit the scope of the present invention.

[0023] The shape of the multifunctional control valve of the present invention is basically similar to that of FLECK5600 and FLECK5600SE.

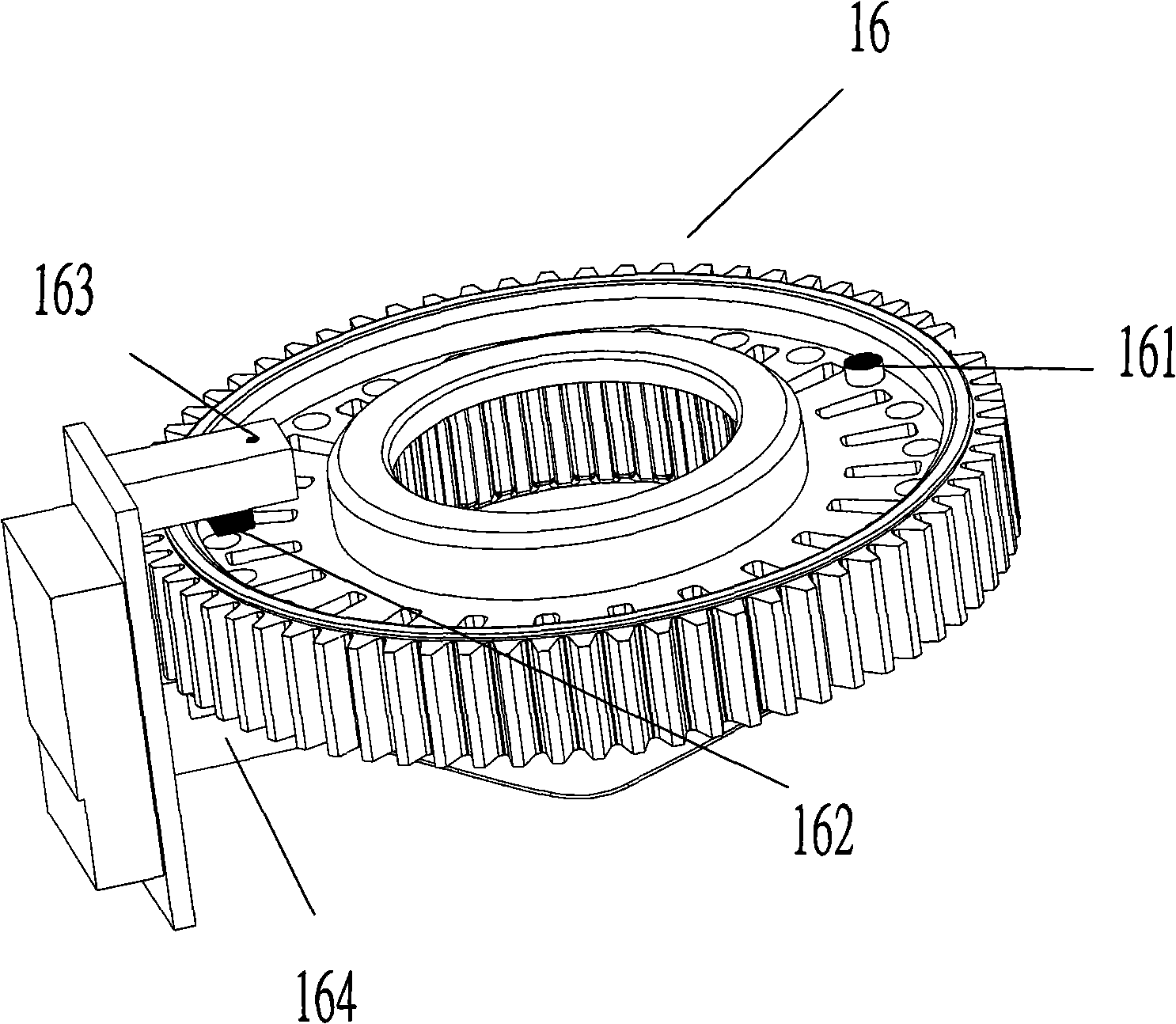

[0024] see figure 1 and figure 2 , and Figure 3 and Figure 4 , as shown in the figure, the valve body of the present invention is completely interchangeable with the valve body of the FLECK5600 or FLECK5600SE control valve, only the controller and the transmission part have been improved, the transmission direction of the FLECK5600 or FELCK5600SE type is vertical, and The mechanical transmission direction of the multifunctional valve of the present invention is horizontal (the final transmission to the piston rod then moves up and down), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com