Material detecting and remote monitoring system for implementing supervision

A technology of remote monitoring system and detection layer, applied in analytical materials, measuring devices, instruments, etc., can solve problems such as insufficient supervision, poor supervision by the supervision department, and inability to prevent artificial cheating, so as to ensure originality and good quality. The effect of facilitating effective regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

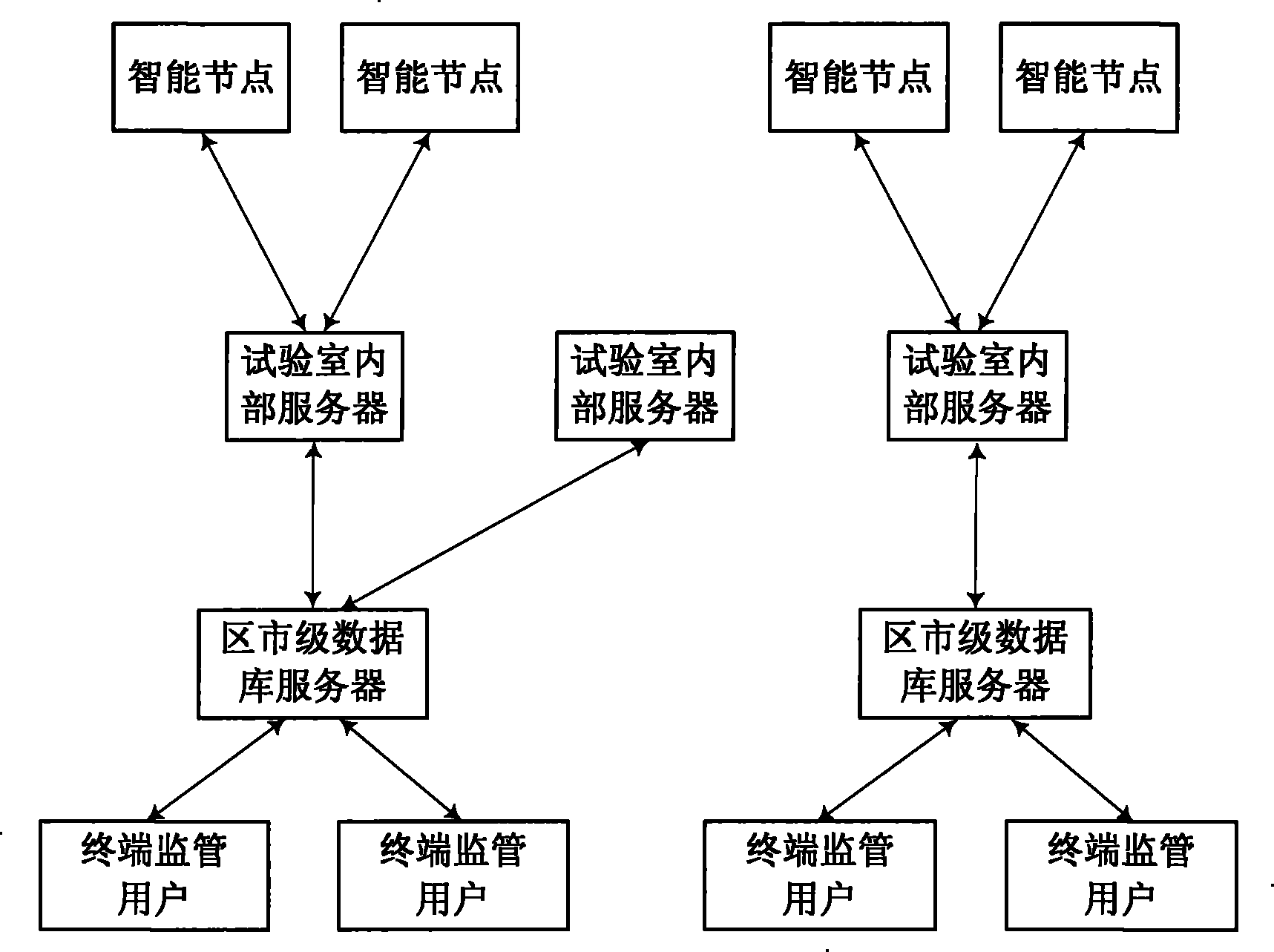

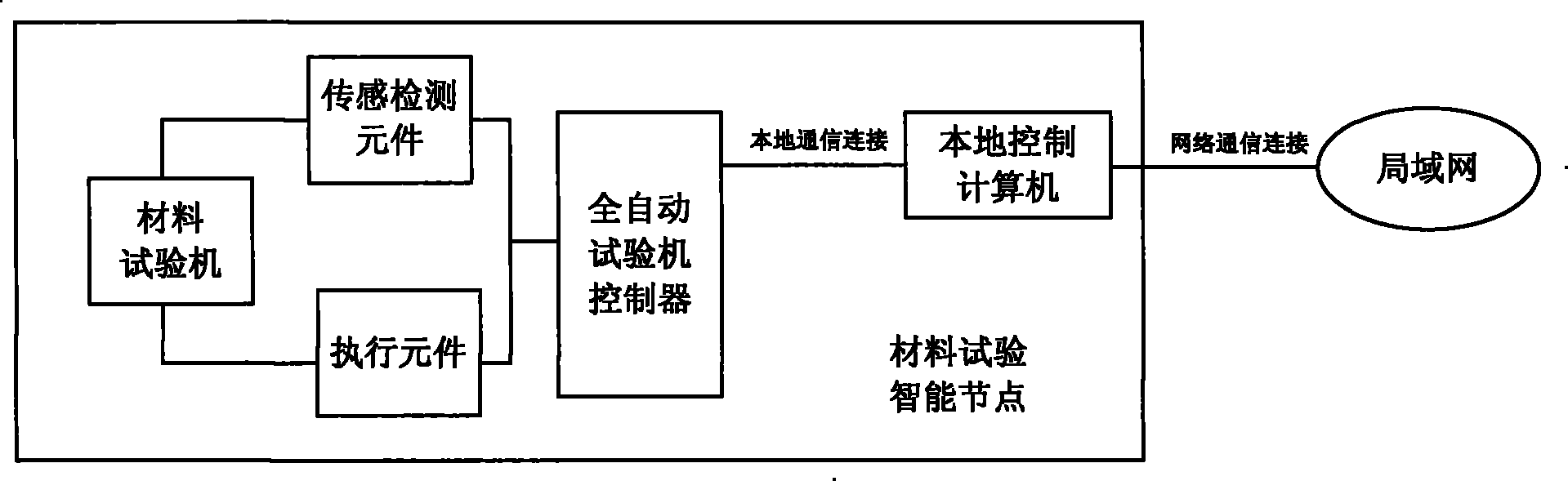

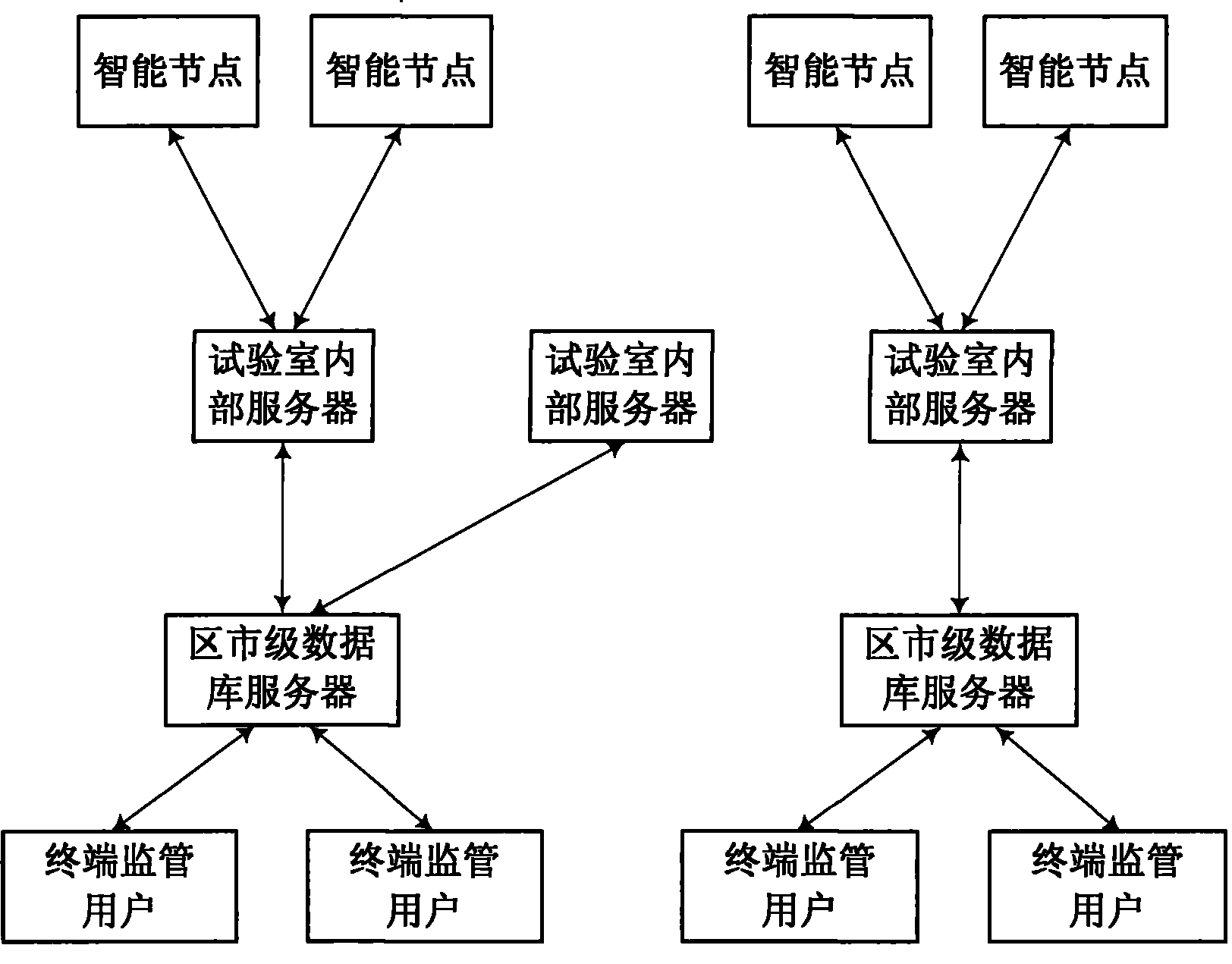

[0018] refer to figure 1 , figure 2 , a material detection and remote monitoring system for realizing supervision, including a material testing machine, sensing and detection elements for detecting load, displacement, and deformation, executive elements and a fully automatic testing machine controller, the material detection and The remote monitoring system includes a control layer, a detection layer and a supervision layer; the control layer includes a material testing machine, a computer for local control, a sensor detection element, an executive element and a fully automatic testing machine controller; the fully automatic testing machine controller Including: a signal acquisition / processing module for collecting various sensor data; a drive execution module for driving actuators; a local data communication module for communicating with a local computer; a remote c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com