Splitlevel shielding socket

A split-layer and shielding layer technology, applied in the field of split-layer shielded sockets, achieves excellent results, stable and reliable performance, strong novelty and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

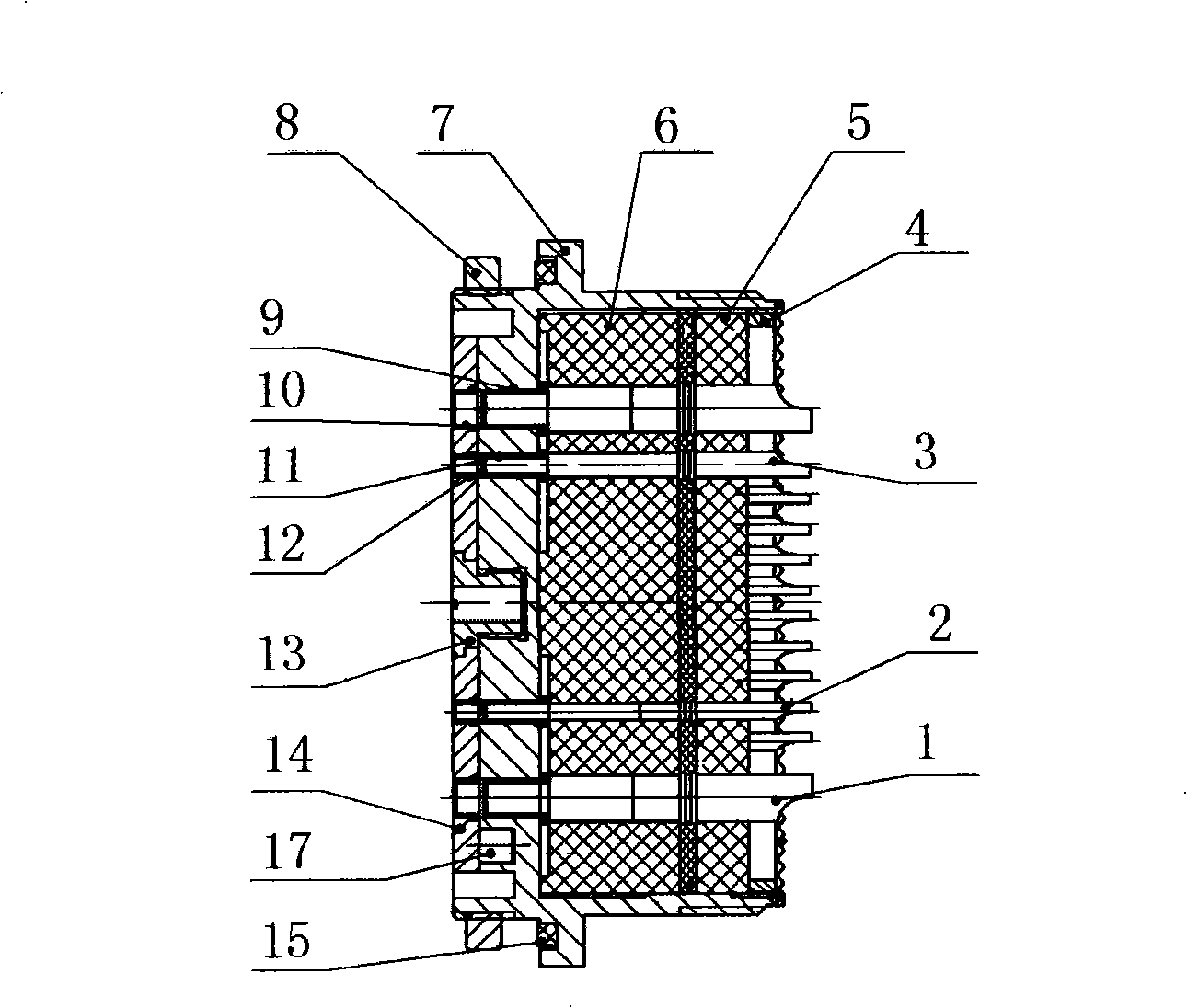

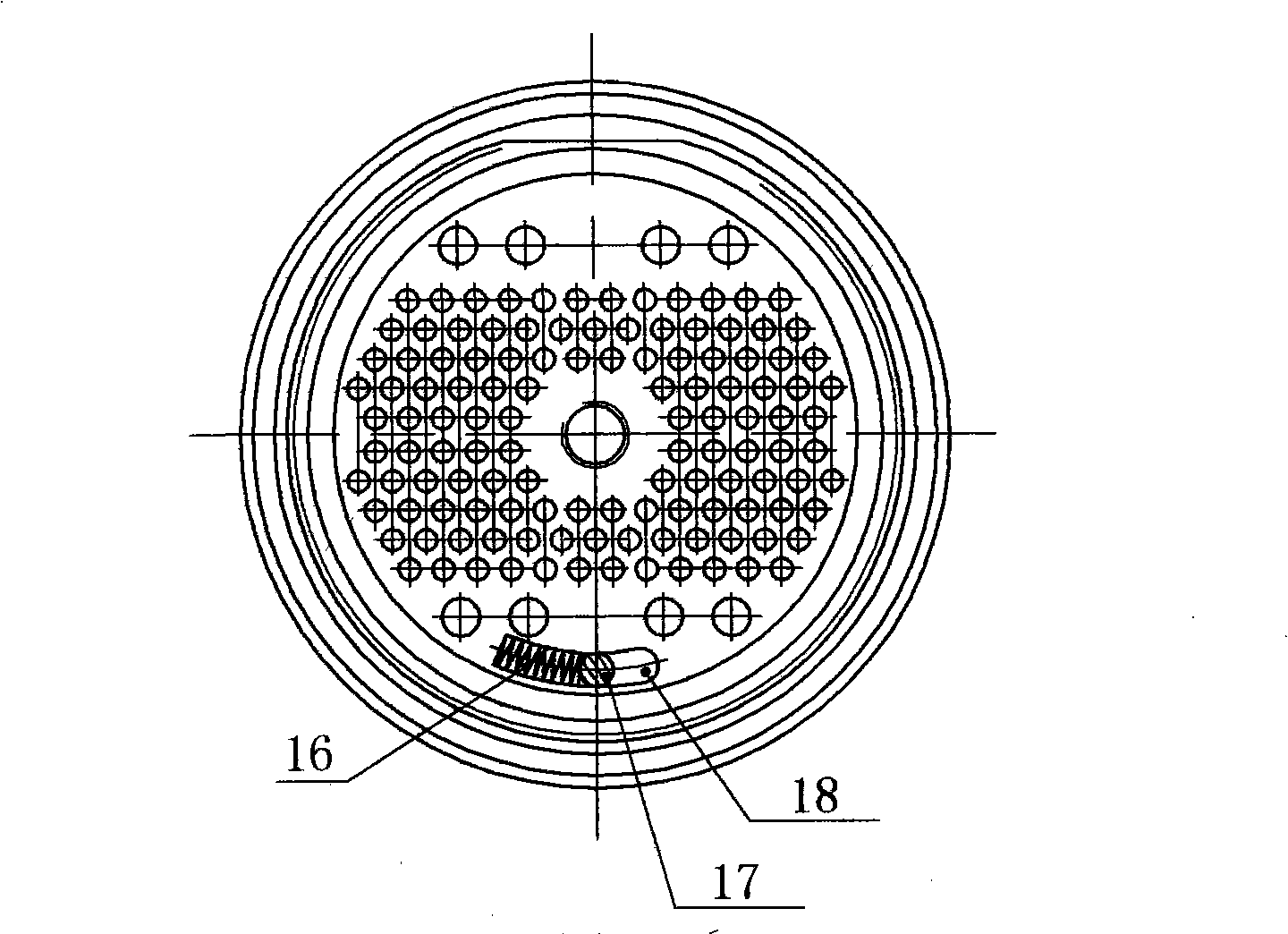

[0013] The split-level shielded socket of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0014] Such as figure 1 As shown, the split-level shielded socket of the present invention includes a housing 7, jacks 1, 2, 3, a pressure ring 4, a lower insulator 5, and an upper insulator 6, and the jacks 1, 2, and 3 are fixed on the upper insulator 6 and the lower insulator 5, the upper and lower insulators are fixed in the housing 7 by the pressure ring 4 to form a stable axial fixation. Silicone rubber is potted between the upper insulator 6 and the lower insulator 5 to realize the sealing of the socket. In order to realize the electromagnetic shielding of the socket, the insertion end of the socket housing 7 is not open like a common connector socket, but is closed with a metal layer to form the lower shielding layer 8 of the socket, and according to the socket in the socket Specifications and quantity, on the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com