Heating soft wire

A technology of flexible wires and silk wires, applied in the field of heating flexible wires, can solve the problems of thicker outer diameters of heating flexible wires, low productivity, and poor mood of heating appliances, so as to achieve work efficiency and reliability, solve safety and Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

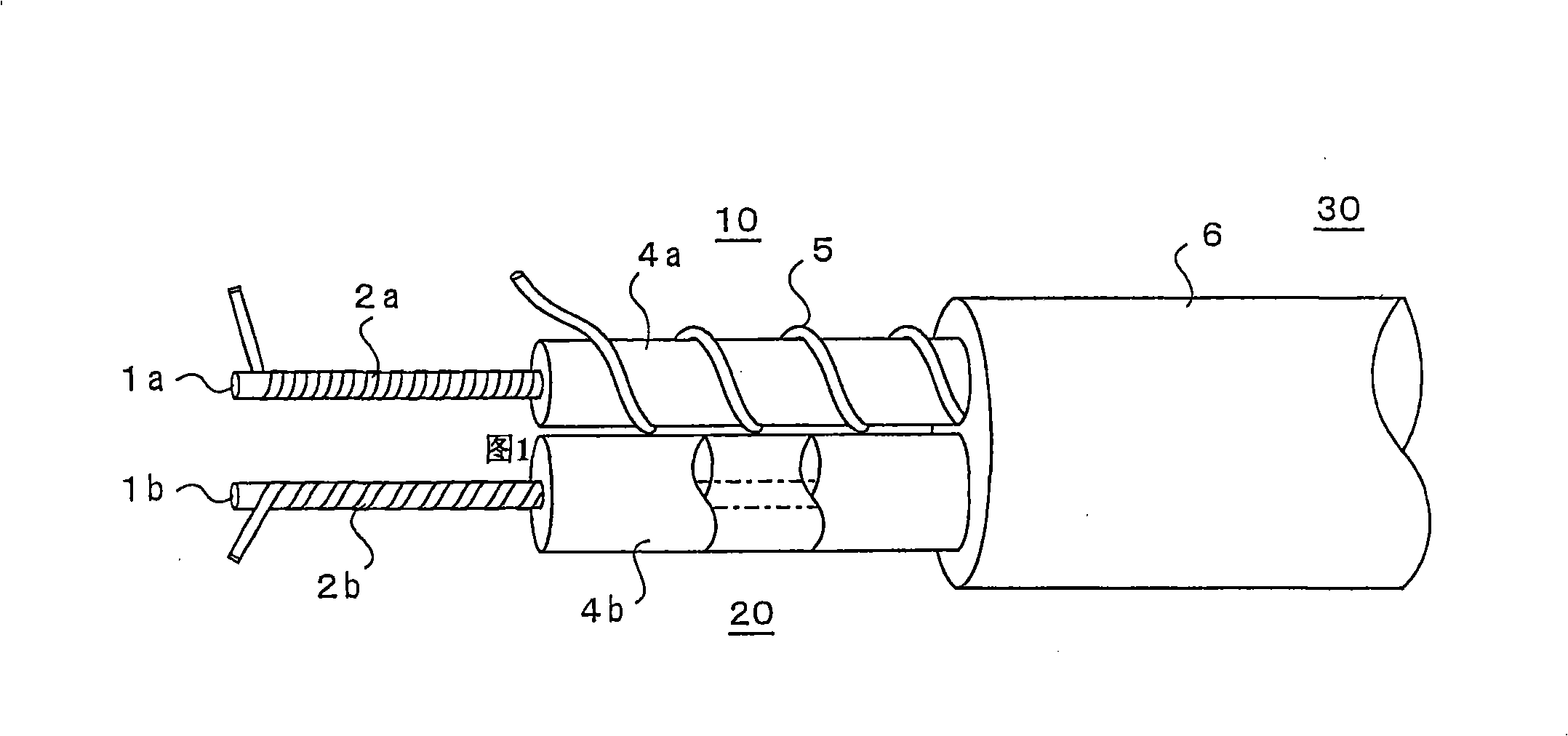

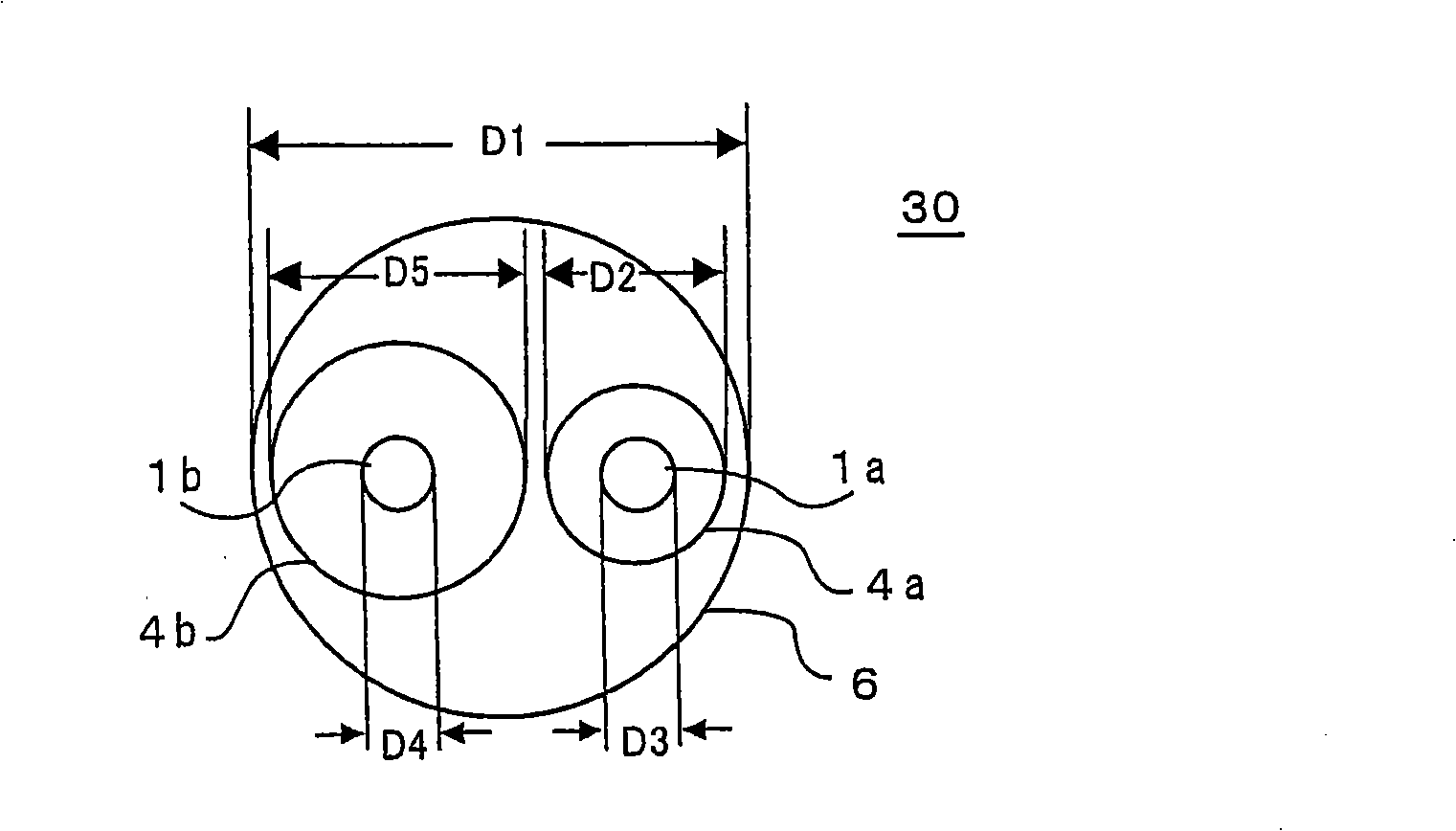

[0043] versus Figure 1A and Figure 1B The data related to the illustrated embodiment is as follows.

[0044] Material of core wire (1a, 1b): polyester fiber bundle

[0045] Diameter of core wire 1a: D3 = 0.3mm

[0046] Diameter of core wire 1b: D4=0.3mm

[0047] Material of outer cover layer 6: heat-resistant vinyl chloride resin

[0048] Diameter of the outer covering layer 6: D1=3.0mm

[0049] Material of cover 4a: Nylon 12

[0050] Diameter of the covering part 4a: D2=0.9mm

[0051] Material of cover 4b: Heat-resistant vinyl chloride resin

[0052] Diameter of the covering part 4b: D5=1.2mm

[0053] Sectional shape (mm) Pitch (mm) Winding direction Material

[0054] Heating wire 2a 0.06×0.42 0.66 right copper

[0055] Heating wire 2b 0.06×0.42 0.69 right copper

[0056] Detection line 5 φ0.09 0.86 left pure nickel

[0057] In addition, the number of detection wires 5 is one, and the twisting pitch is selected so that the resistance value at 20° C. is 1030 Ω. Whe...

Embodiment 2

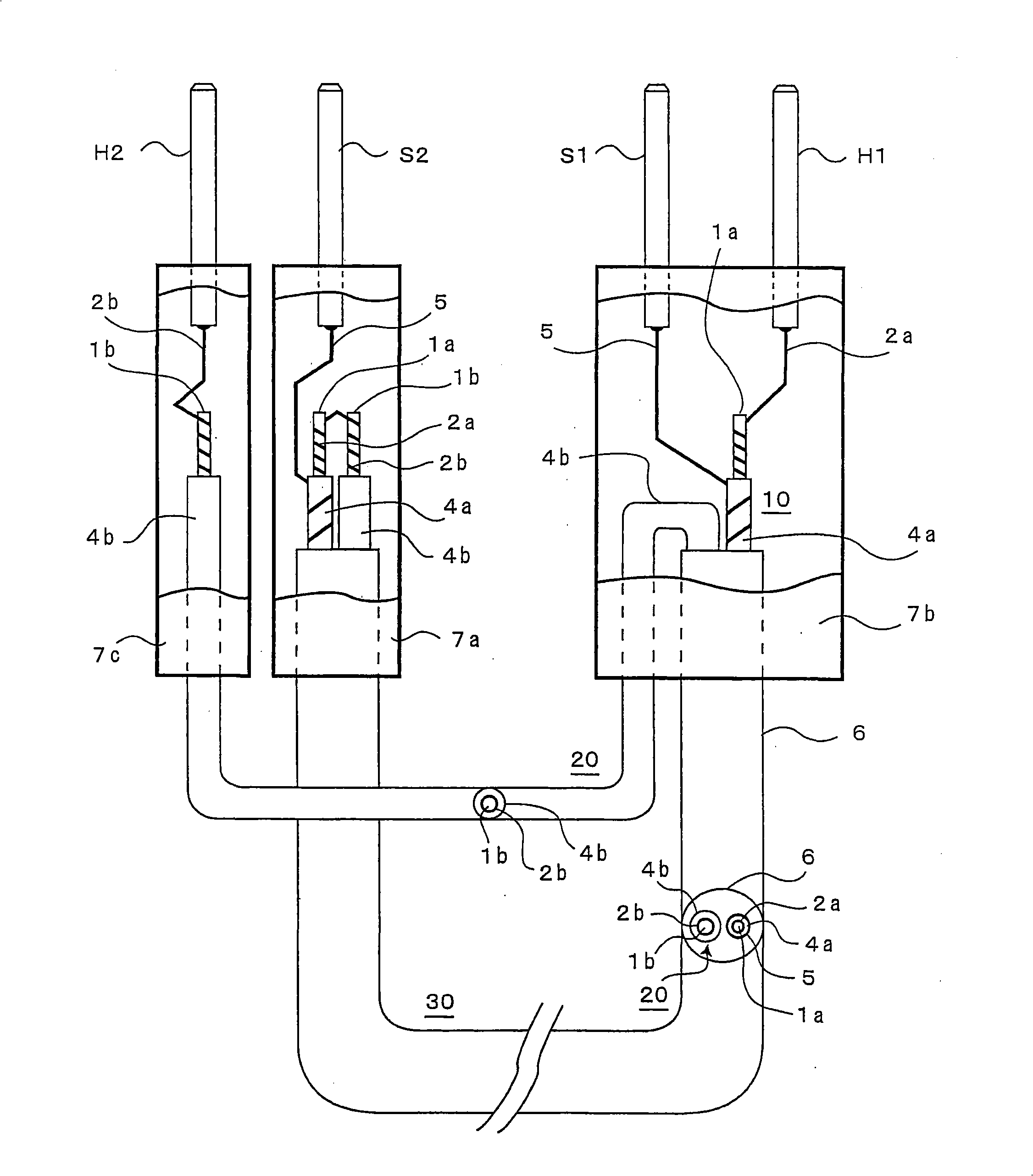

[0064] The covering portion 4a of the heating wire 2a of the first flexible cord element 10 of Example 1 was replaced with a heat-resistant vinyl chloride resin. In this heating cord, under exactly the same conditions as in the first embodiment, a short circuit between the heating wire 2a or 2b and the detection wire 5 caused by the abnormal heating of the first flexible cord element 10 and the second flexible cord element 20 is performed. test. As a result, the covering portion 4a of the first cord element 10 melted, and it was confirmed by electrical measurement that the heating cord 2a was in contact with the detection cord 5.

[0065] Variations

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com