Circuit, shrink fixing and regulation method

A circuit and intermediate circuit technology, applied to the circuit, can solve problems such as oversize, and achieve the effects of increasing load, optimizing size, and optimizing overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

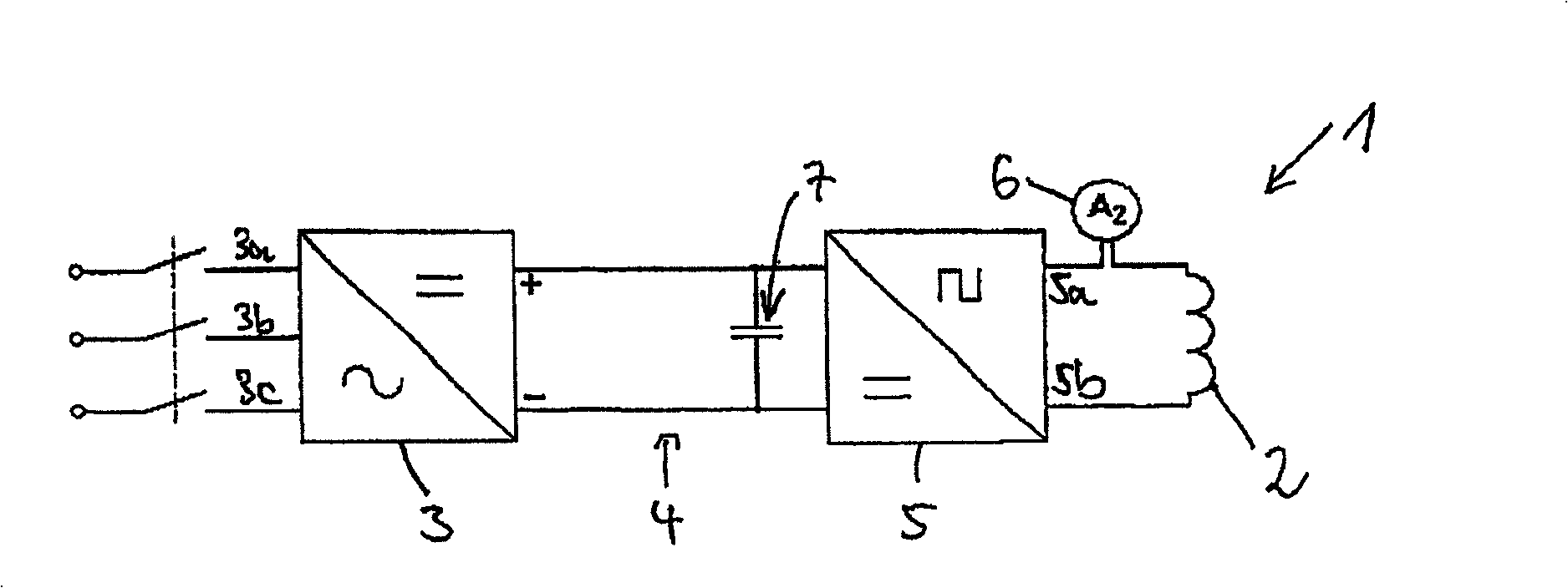

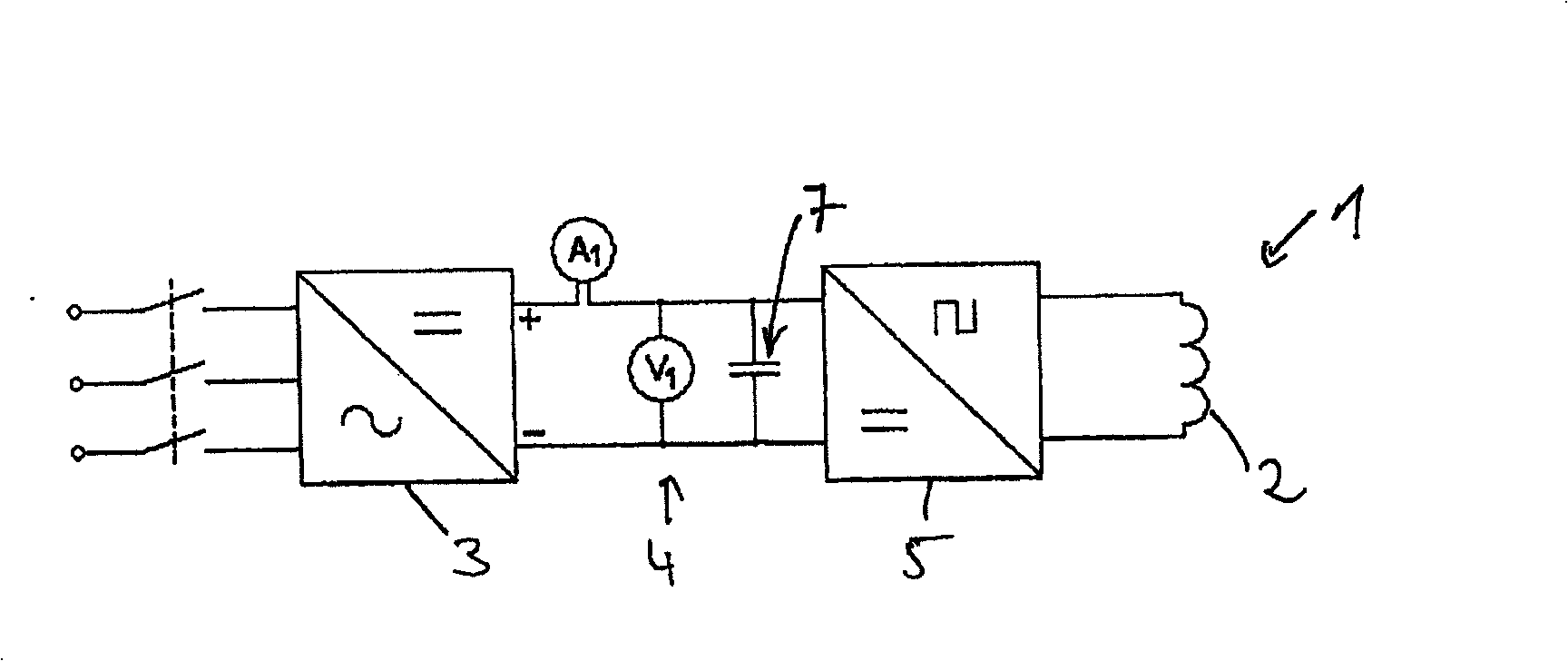

[0033] exist figure 1 A circuit 1 for controlling the power supply to an induction coil 2 according to the invention is shown in . This circuit is equipped on a circuit board and thus constitutes a control circuit board for supplying power to the coil 2 .

[0034] In particular, the induction coil 2 acts as a shrink fitting of the heating tool. An induction coil 2 generates an alternating electromagnetic field to which the shrink fit is connected. Heat is generated by the Eddy current generated in the shrink fitting and / or by changing the magnetization of the shrink fitting made of ferromagnetic material, so that the shrink fitting expands so that the tool can be inserted.

[0035] During the heating process, it is necessary to supply the induction coil 2 with a maximum power as constant as possible, taking into account the maximum permissible load of the components. Of course, on the one hand the maximum load limits of the induction coil 2 and the power electronics must be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com