Desulphurization method of amine liquid with high removal rate of hydrogen sulfide and special equipment

A desulfurization device, hydrogen sulfide technology, applied in the direction of hydrogen sulfide, chemical instruments and methods, separation methods, etc., can solve the problems of high energy consumption, large steam consumption, low hydrogen sulfide removal rate, etc., and achieve high removal rate , good absorption effect, saving reboiler steam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

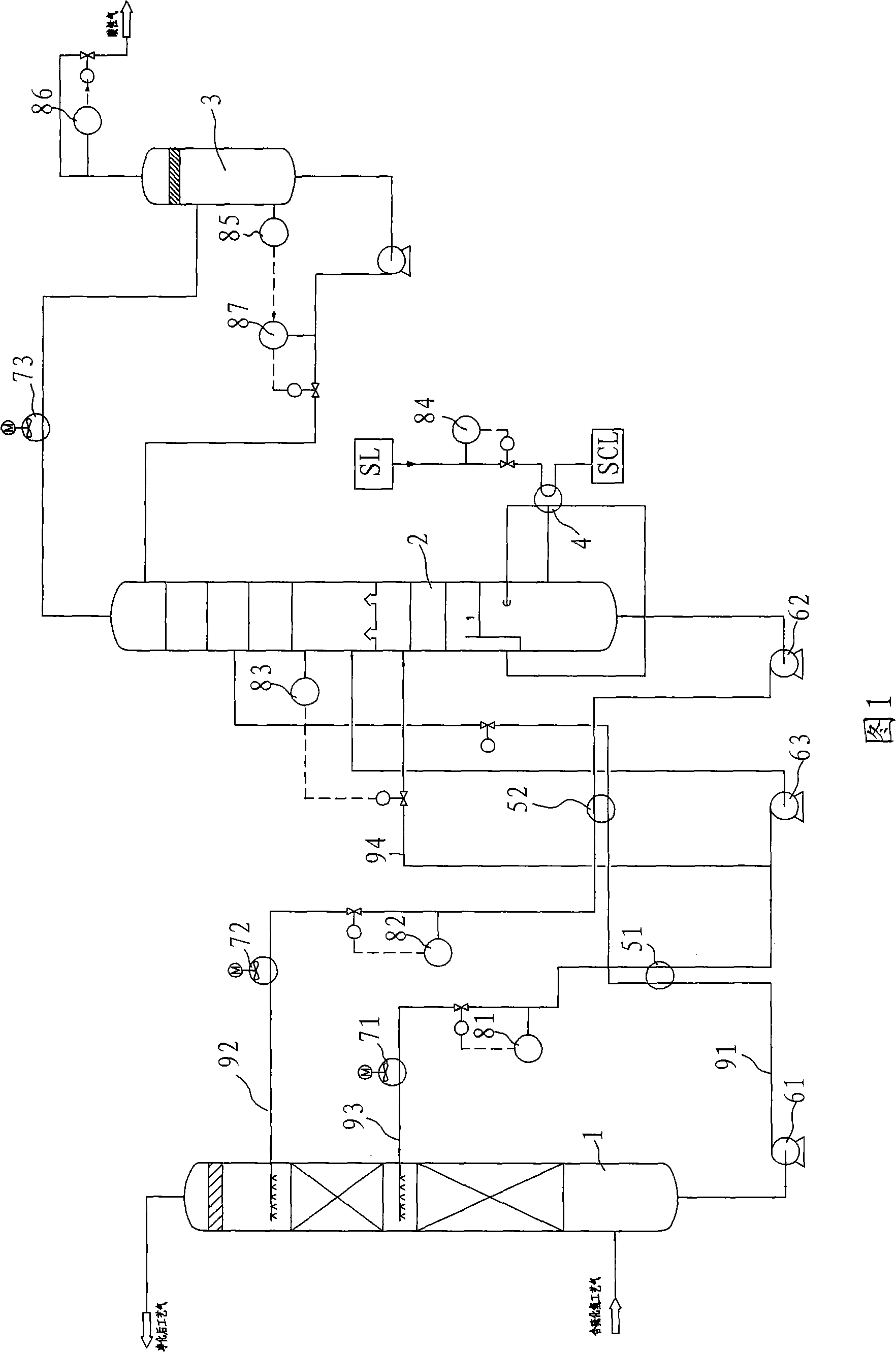

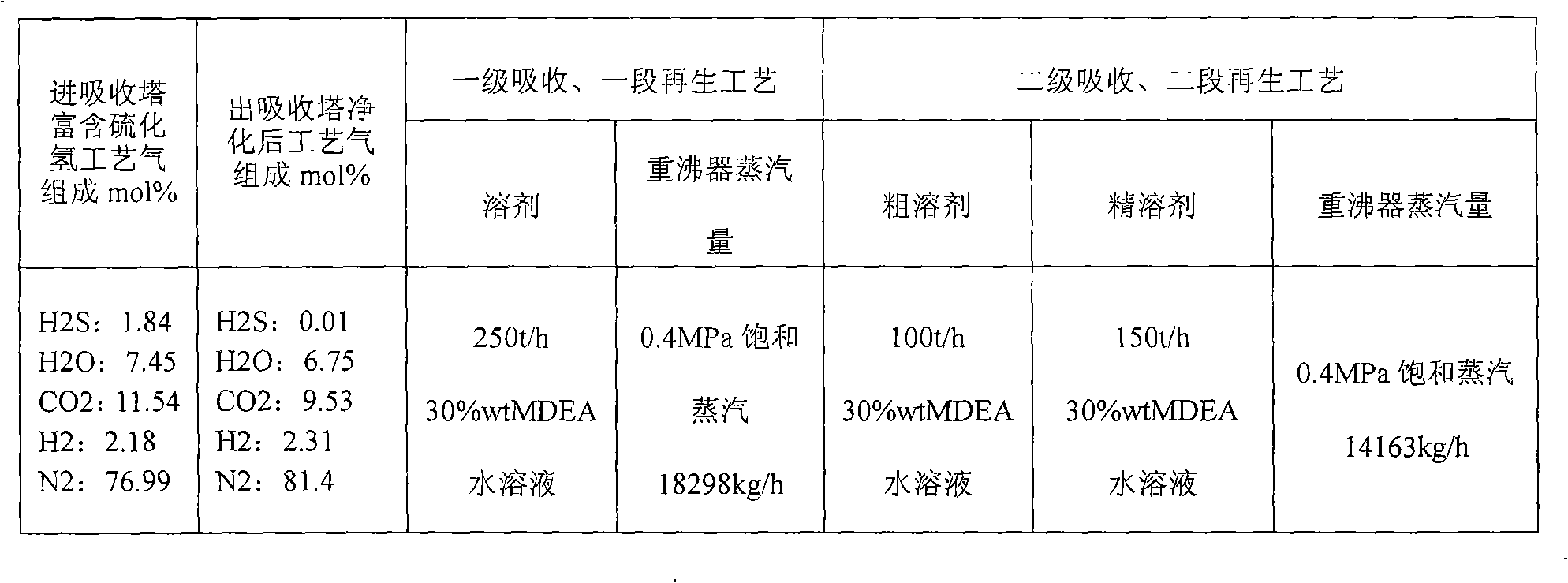

[0020] Embodiment: Referring to Fig. 1, the amine liquid desulfurization device in this embodiment mainly includes an absorption tower 1, a regeneration tower 2, a first heat exchanger 51, a second heat exchanger 52, a first pump 61, a second Pump 62, the third pump 63, the first air condenser 71, the second air condenser 72, the third air condenser 73 and the first pipeline 91, the second pipeline 92, the third pipe for connecting the above-mentioned equipment Road 93 and fourth pipeline 94, the regeneration tower 2 is divided into an upper section and a lower section, and the absorption tower 1 has a bottom outlet, a middle inlet and an upper inlet.

[0021] One end of the first pipeline 91 is connected to the outlet at the bottom of the absorption tower 1, and the other end is connected to the inlet of the upper section of the regeneration tower 2. The first pump 61 is installed in series on the first pipeline 91. The heated inlet and heated outlet of the first heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com