System for purifying phosphate fog of hot dip galvanizing machine group in cold-rolling mill

A purification system and phosphate technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of costing hundreds of thousands of yuan, and achieve the effect of compact structure, convenient adjustment and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and drawings, but the present invention is not limited.

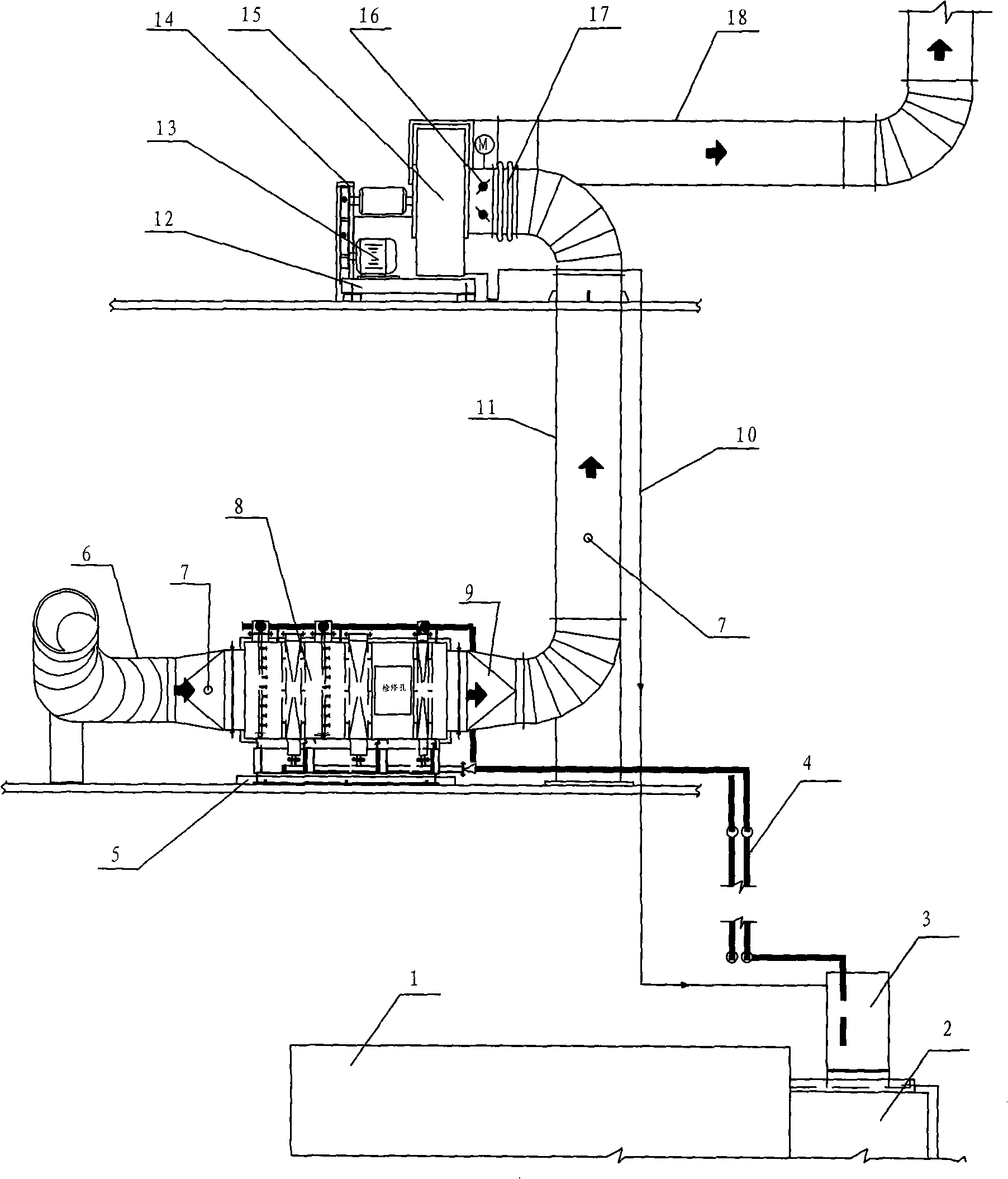

[0019] The phosphate mist purification system of the hot-dip galvanizing unit of the cold rolling plant provided by the present invention has a structure such as figure 1 Said: It is mainly composed of a horizontal purifier 8 and a ventilation system. The ventilation system is mainly composed of a centrifugal fan 15, an electric motor 13, an electric regulating valve 16, and a ventilation pipe. The inlet and outlet of the centrifugal fan 15 are each connected by a flexible connector 17 to the air supply pipe 11 and the exhaust pipe 18. Connected. At both ends of the horizontal purifier 8 are the air inlet pipe 6 and the air supply pipe 11 respectively. An electric regulating valve 16 is installed between the air supply pipe 11 and the inlet of the centrifugal fan 15.

[0020] The centrifugal fan 15 drives the impeller to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com