Bonding method of dissimilar materials made from metals and bonding structure thereof

A technology of dissimilar materials and metal materials, applied in metal processing equipment, welding/cutting media/materials, welding/welding/cutting items, etc., can solve problems such as excessive resistance heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

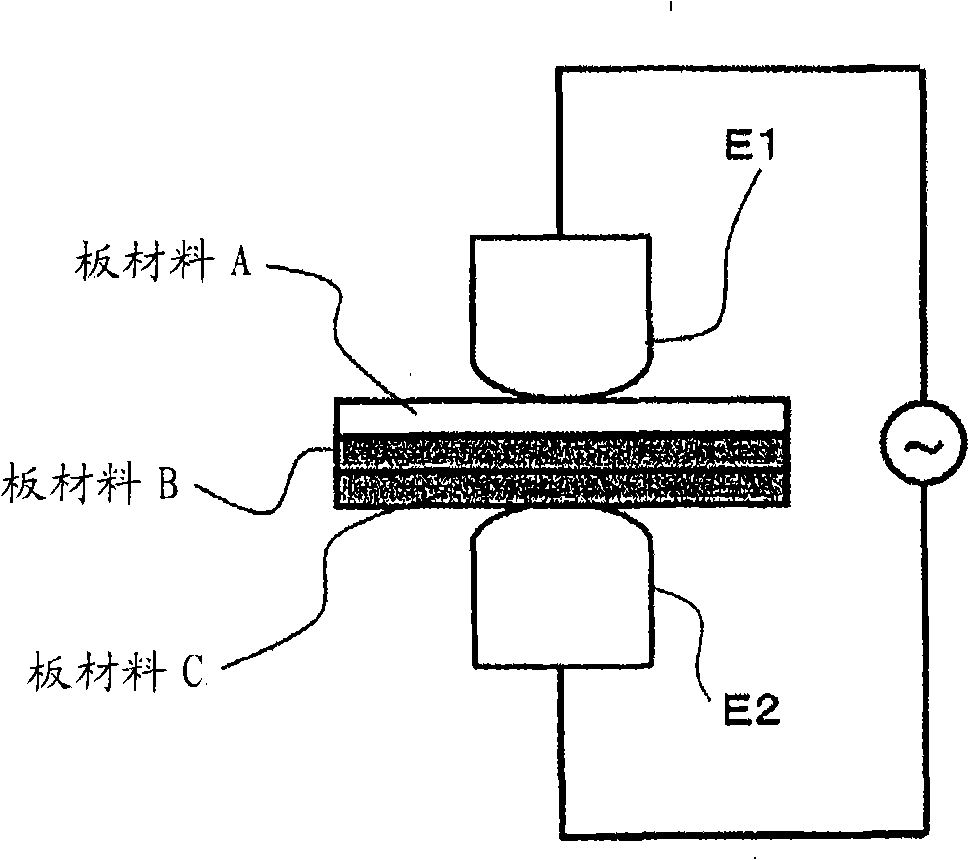

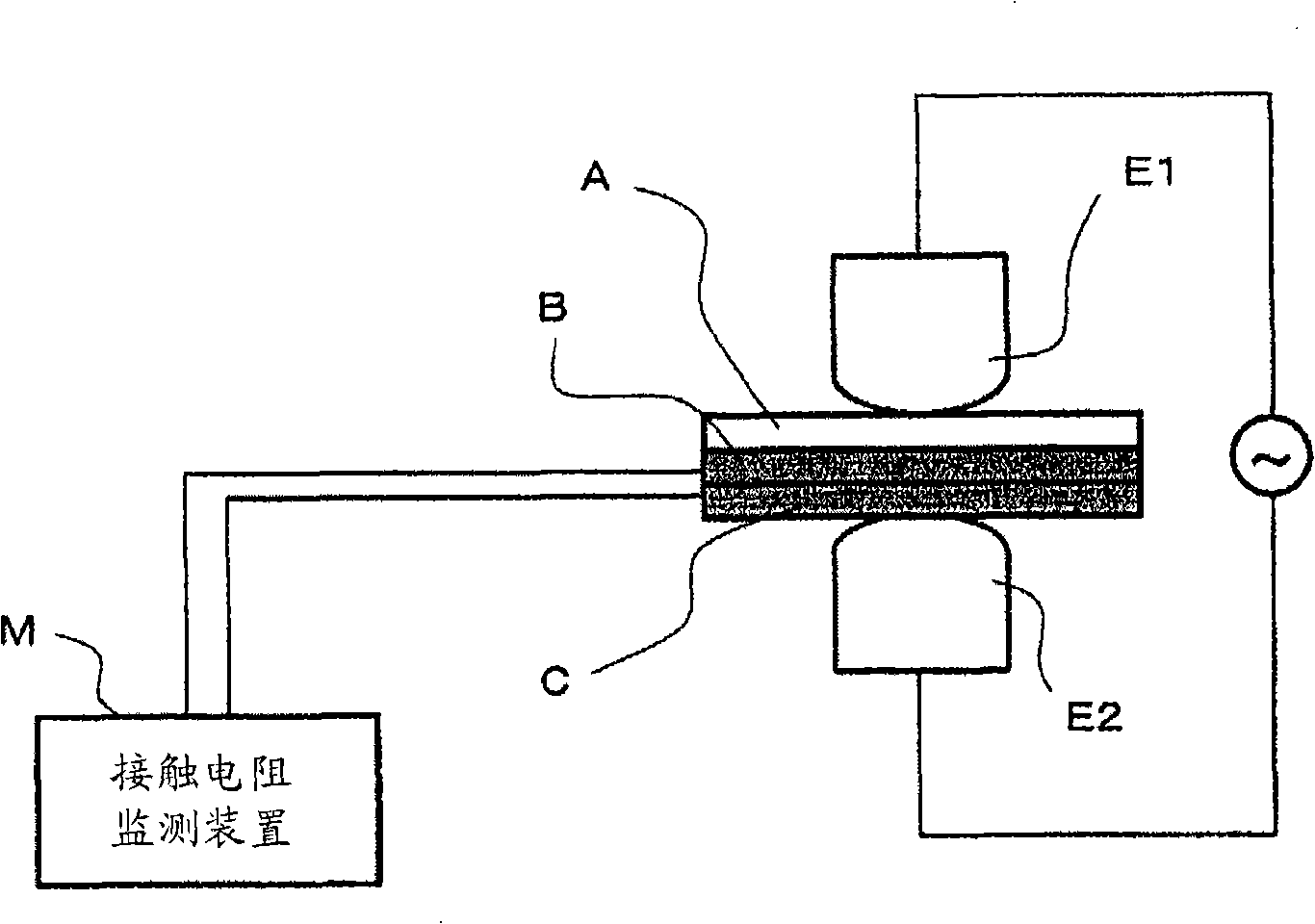

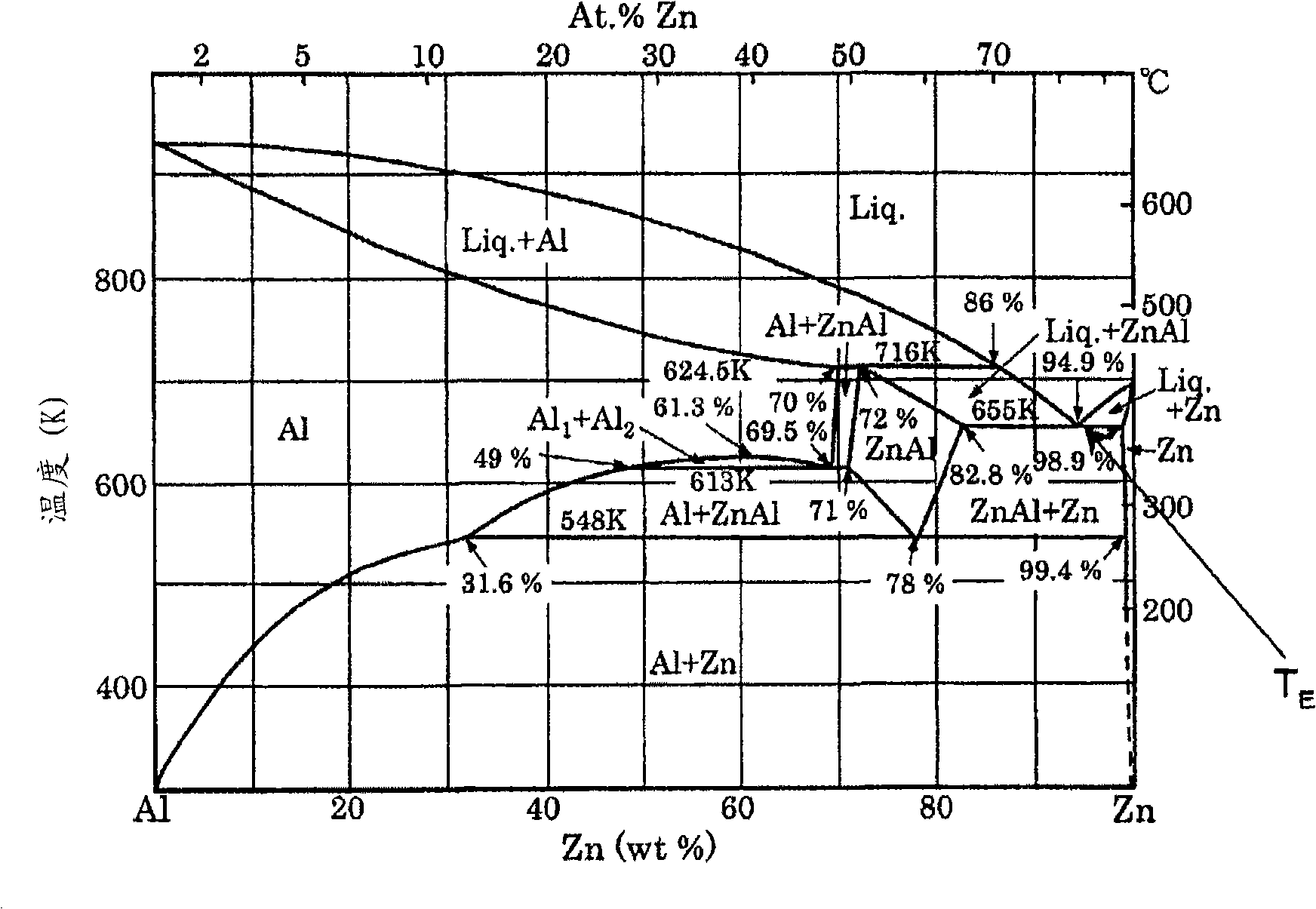

[0020] The bonding method disclosed here can sufficiently secure bonding strength in each interface in which a desired nugget diameter can be formed while preventing reduction in material thickness on the low melting point side. This method can be utilized when three or more sheets of dissimilar materials made of metal are laminated and joined by a resistance welding operation. This method can also be utilized for combinations of materials having both a homogeneous material interface and a dissimilar material interface where the resistive heating in the dissimilar material interface is less than the resistive heating in the same material interface due to the difference in contact resistance of the two interface diameters . A bonded structure obtained by such a bonding method is also disclosed. Engagement structures are, for example, components of a vehicle, such as doors, hoods, and the like.

[0021] The present invention is explained based on the following examples, althou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com