Control method for equilibrium operation of converter dust-removing flue cooling fan

A cooling fan and balanced control technology, which is applied in the direction of using electric methods for temperature control and manufacturing converters, etc., can solve the problems of low power-on duration of the backup fan motor, unbalanced fan motor running time, and short fan motor running time. To achieve the effect of saving investment, reducing the continuous rate of power supply and improving the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

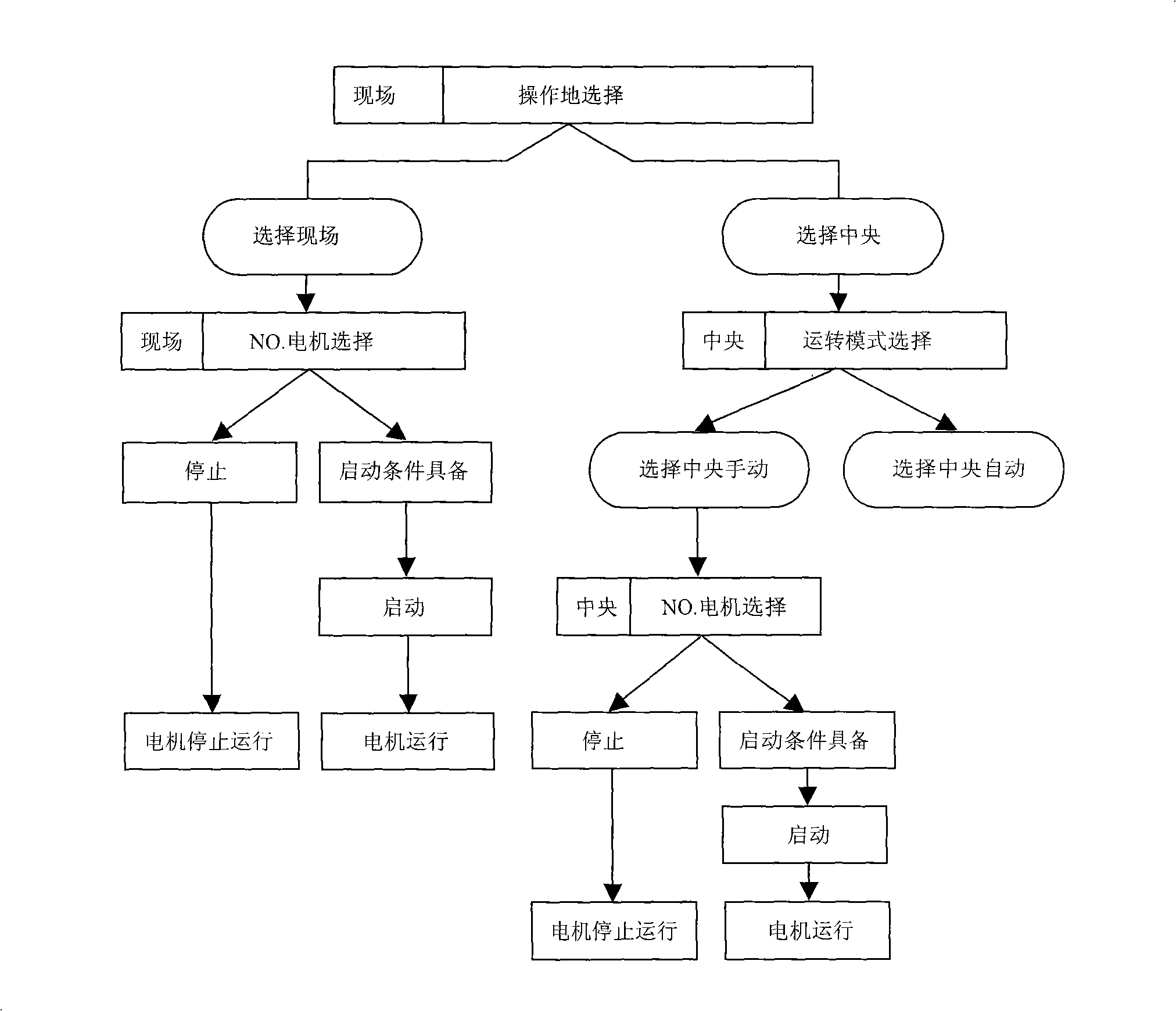

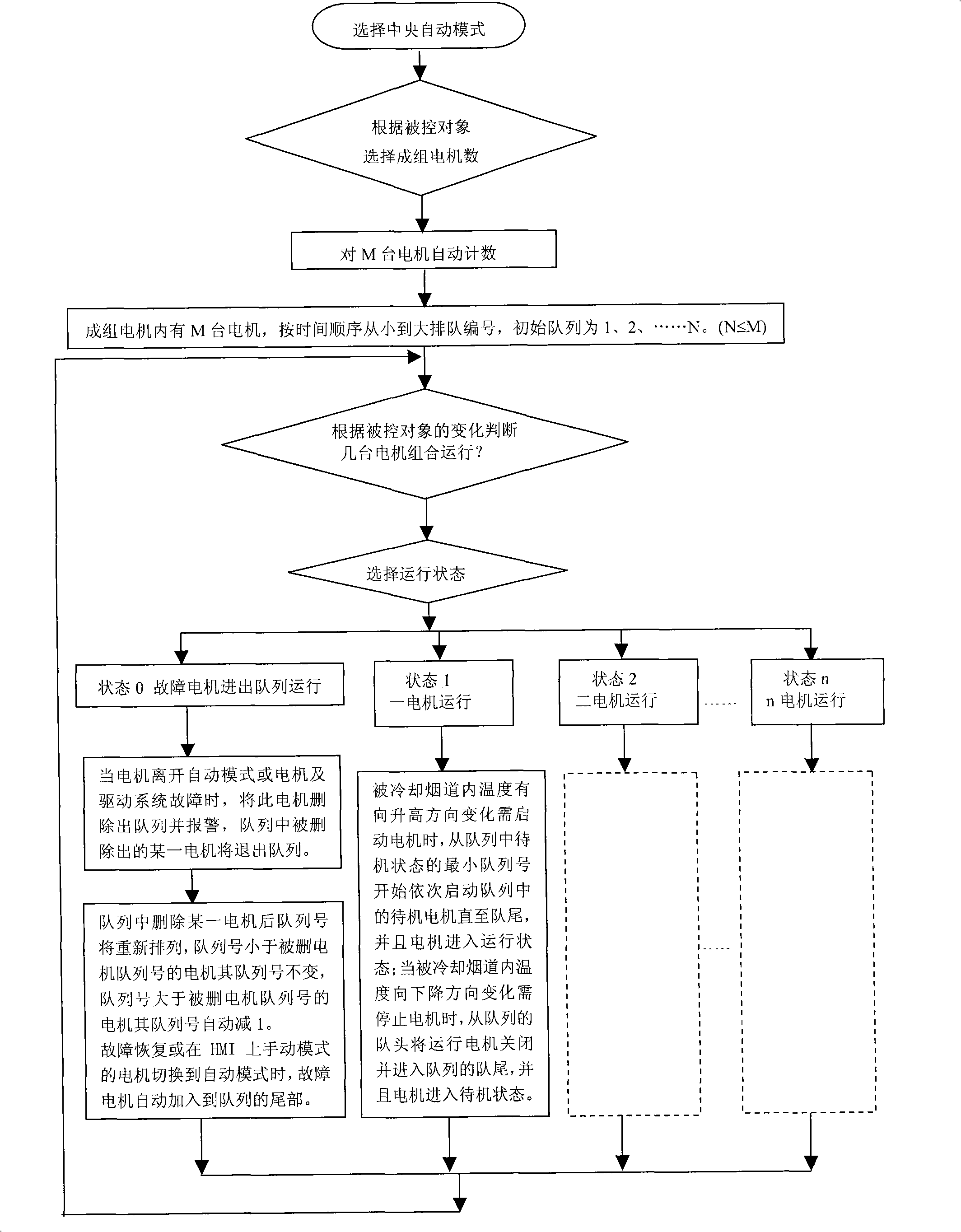

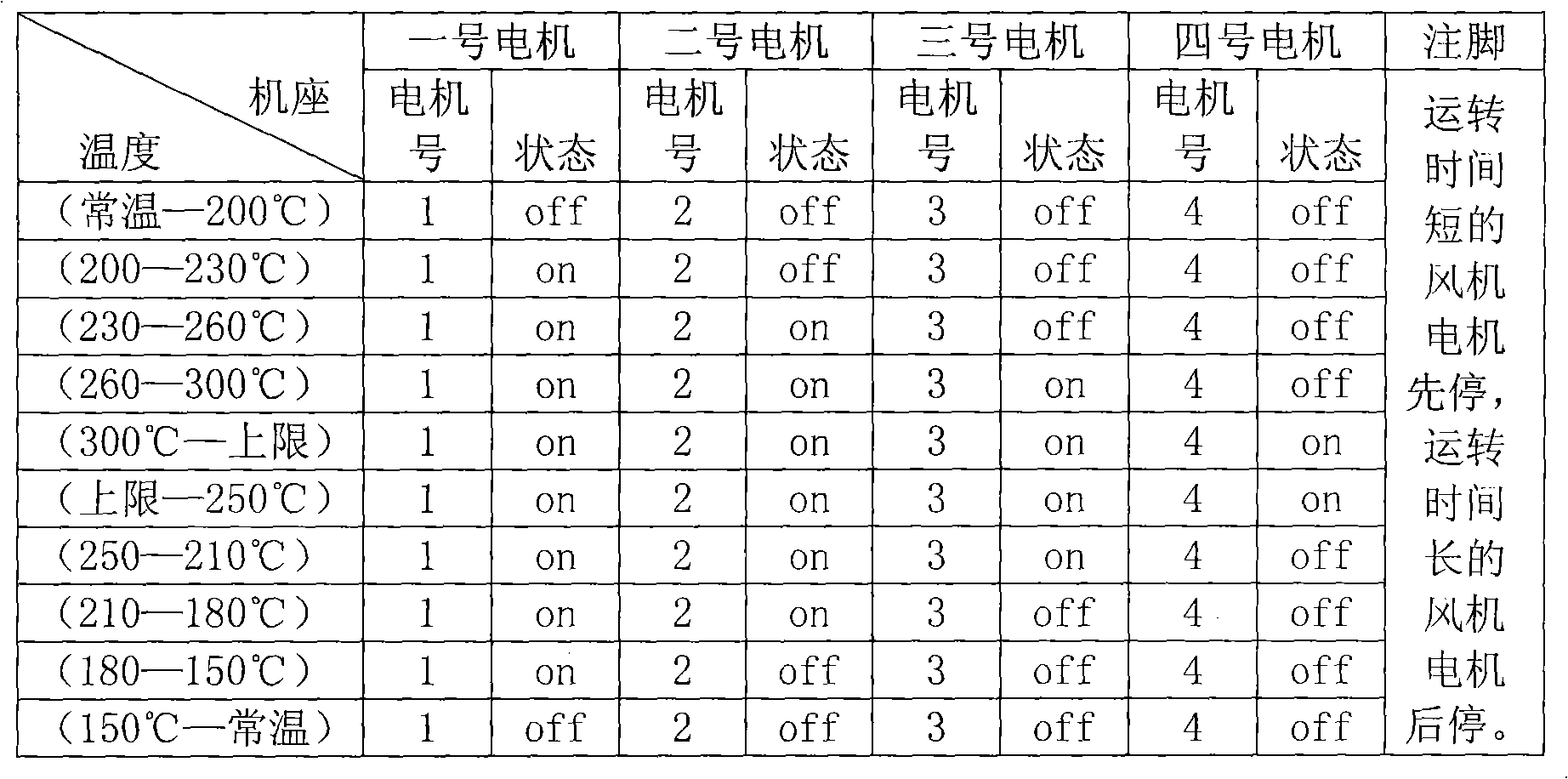

[0032] see figure 1 , a converter dust removal flue cooling fan operation control method, using the site manual, central (remote) manual, central (remote) automatic three control modes. The on-site manual control mode is used for starting and stopping the motors in the case of on-site maintenance and on-site testing; the central (remote) manual control mode is used for manually starting and stopping each motor on the human-machine interface (HMI); the central (remote) automatic control The method is to automatically start and stop a certain motor in the group according to the change of the controlled object.

[0033] Each motor has an on-site operation box, and there is a selection switch for on-site and central on the operation box. The on-site operation enjoys the highest priority. Once the operation right of a fault-free motor is switched f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com