Des-backbone winding ring chucking appliance for optical fiber gyroscope without rise optical fiber ring

A technology of fiber optic gyroscope and fiber optic ring, which is applied in the direction of Sagnac effect gyroscope, etc., can solve the problems of fiber optic coil stress, uneven temperature field distribution, coil extrusion, unreasonable heat flow direction of conduction, etc., and achieve miniaturization , good vibration performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

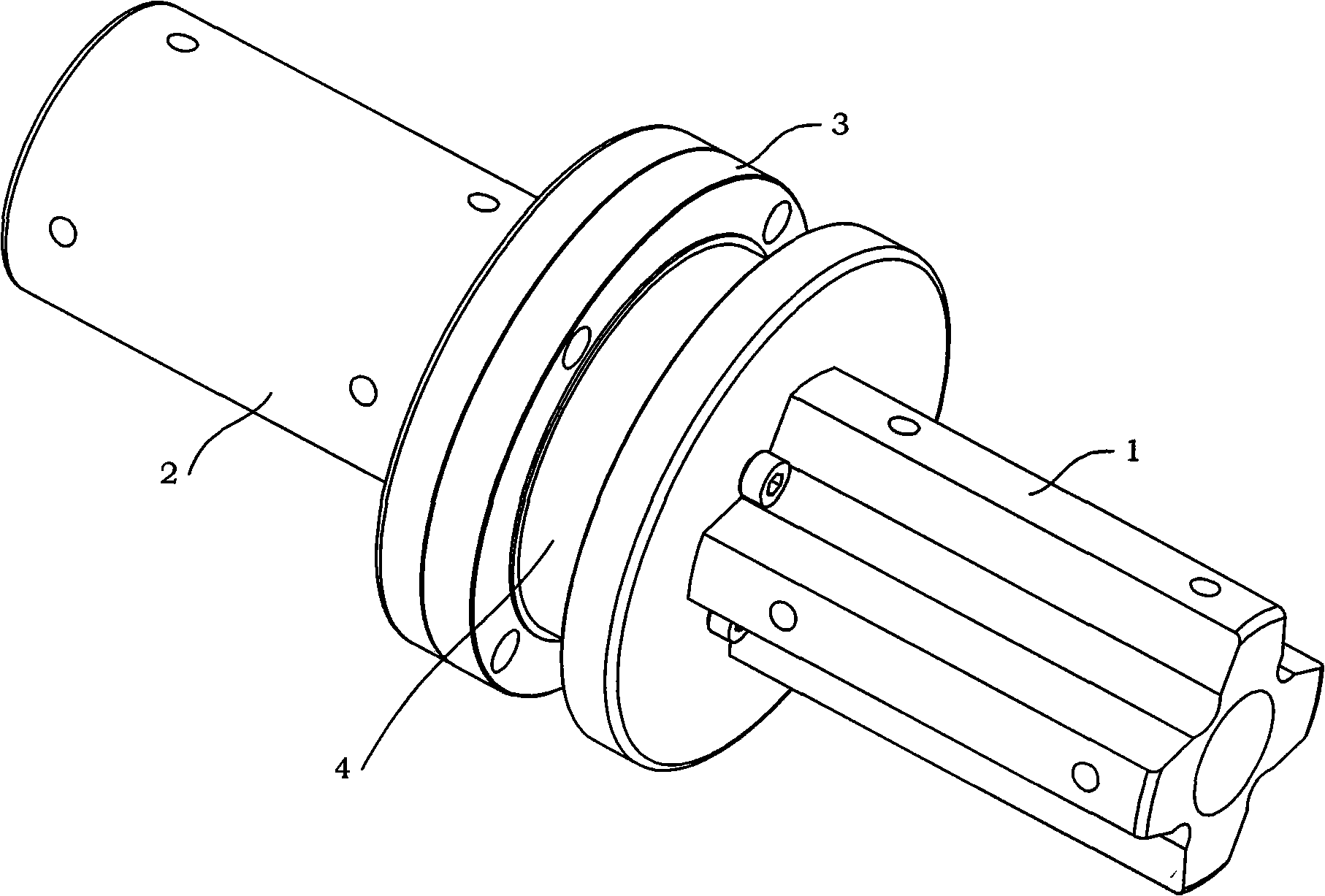

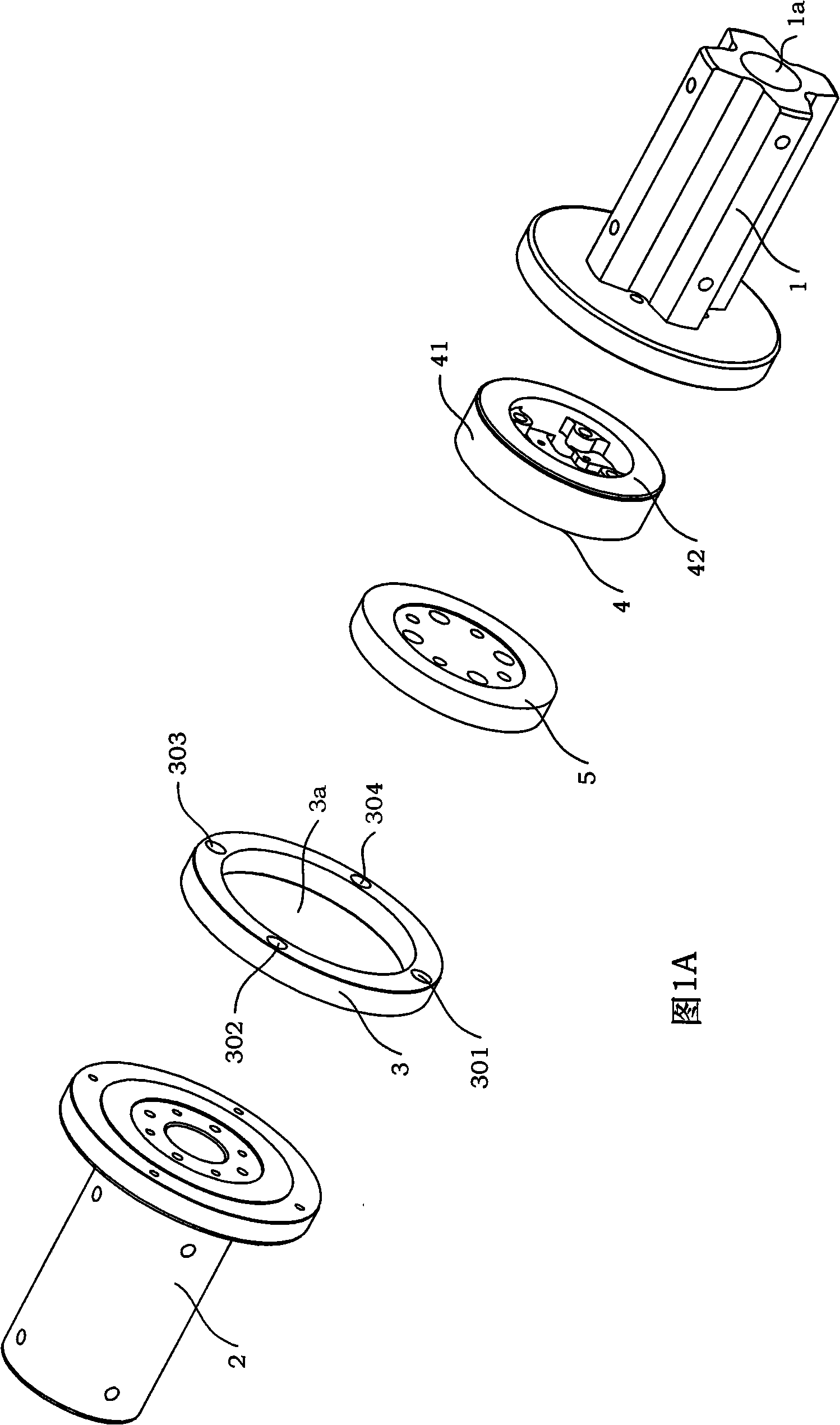

[0028] see figure 1 , figure 1 As shown in A, the present invention is a frame-free ring clamp for fiber optic rings without an upper edge. The frame-free ring clamp includes a ring A clamp 1, a ring B clamp 2, a ring 3, an optical fiber Ring 4, off-shelf ring 5, (see figure 1 Shown in A) From left to right, the layout is the ring B clamp 2, the ring 3, the detachment ring 5, the optical fiber ring 4, and the ring A clamp 1. The ring 3 is installed on the outer ring of the end face 2b of the ring B fixture 2; the detached ring 5 is set in the ring 3 and installed on the D boss 21 of the ring B fixture 2; one end of the optical fiber ring 4 The other end of the optical fiber ring 4 is in contact with the B cavity 11 of the ring A clamp 1; the ring A clamp 1 and the ring B clamp 2 are connected by screws.

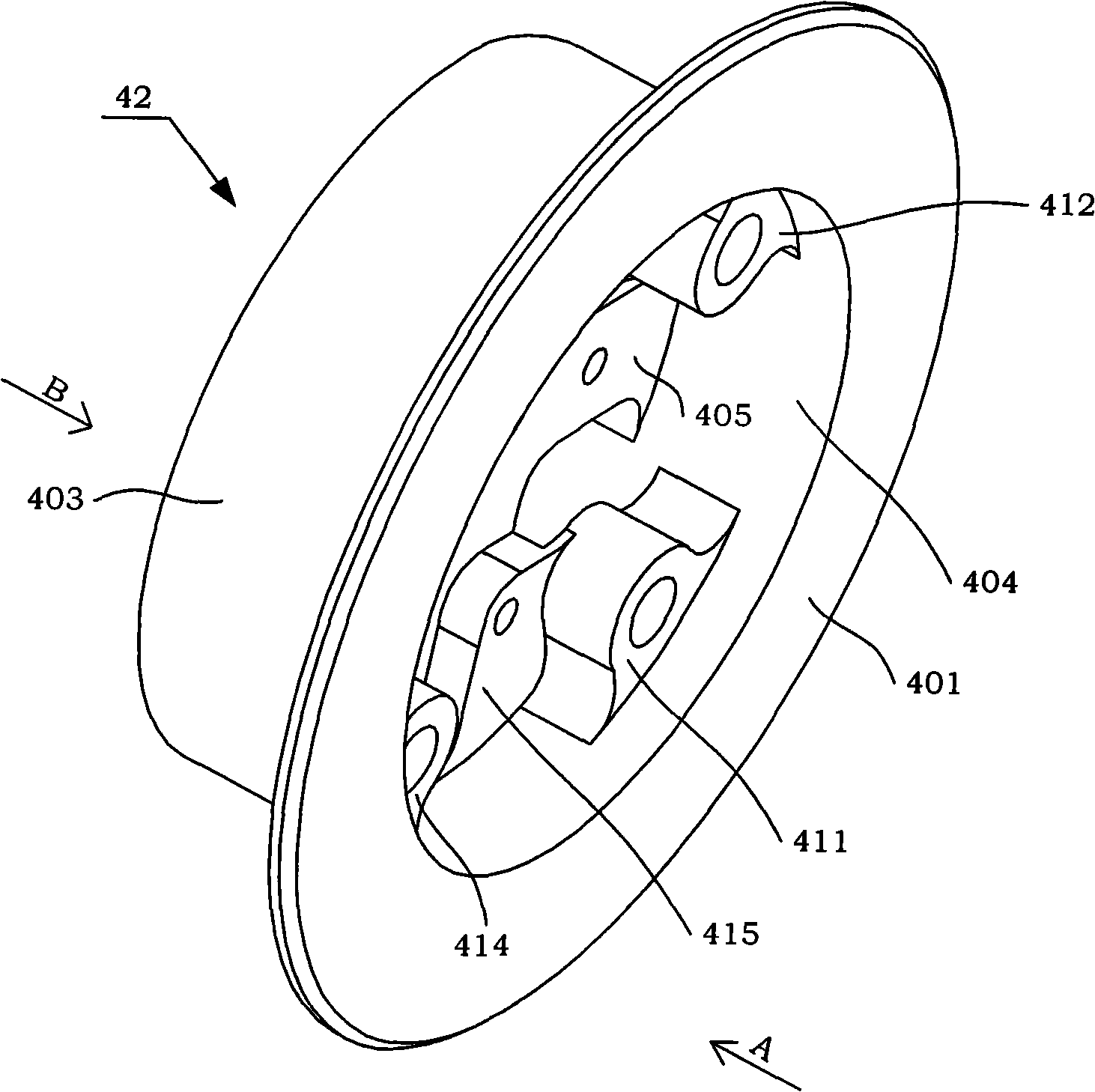

[0029] see figure 1 A. figure 2 As shown, the optical fiber ring 4 is composed of an optical fiber coil 41 and an optical fiber skeleton 42. The optical fiber skeleton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com