Yoghourt fermentation cabinet and method for producing fermented yoghourt

A yogurt, constant temperature fermentation technology, applied in the direction of milk preparations, biochemical equipment and methods, bioreactor/fermenter combination, etc., can solve the problems of imperfection, unstable content of lactic acid bacteria, and impossibility of breakthrough, etc., to achieve survival The effect of time improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

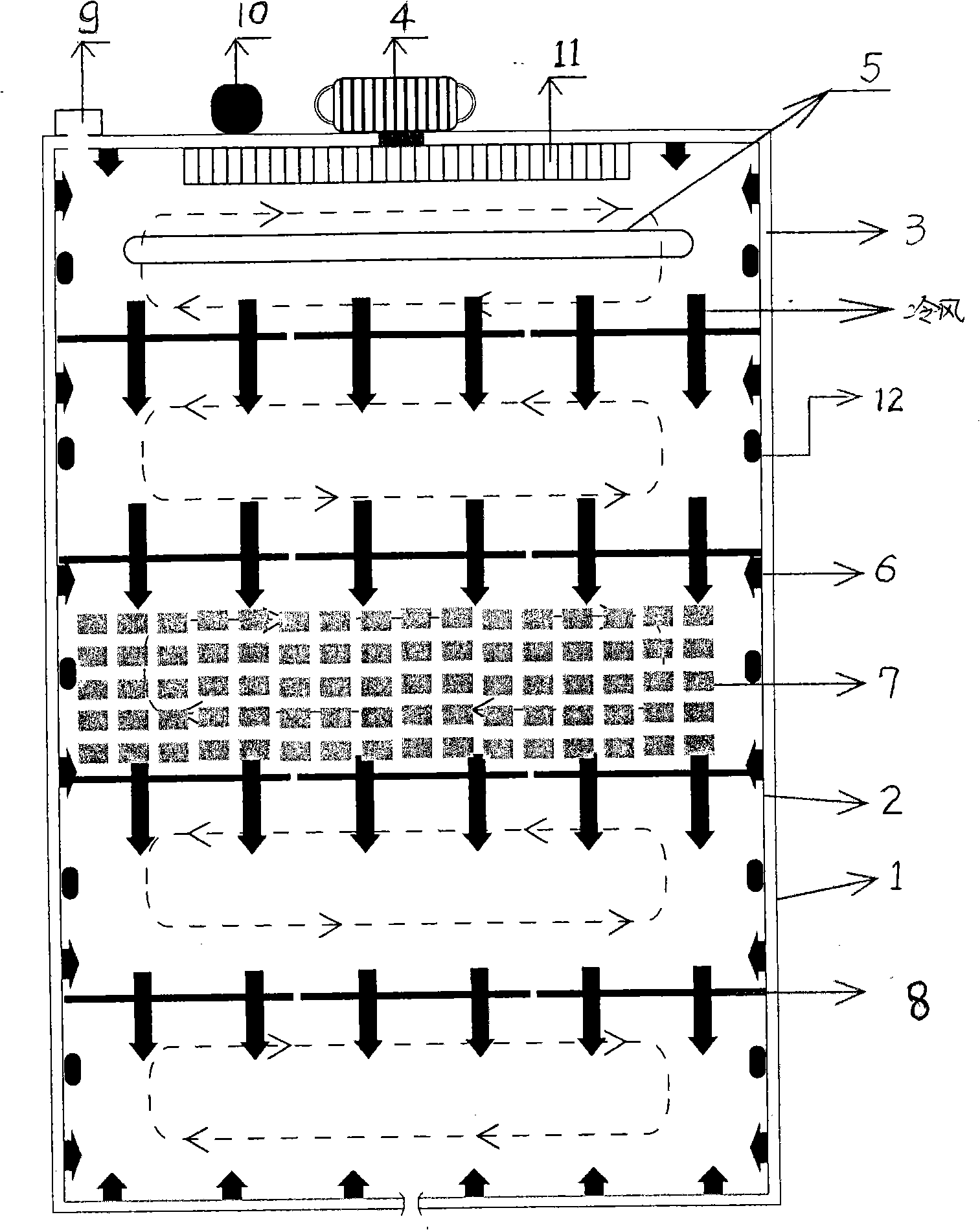

[0026] see figure 1 , commercial yogurt fermentation cabinet, including heat preservation part, sterilization and locking part, constant temperature heating and locking part, intelligent electronic control lock, manual external lock head and constant temperature refrigeration part, etc. There is a door body on the box body, the cooling, heat preservation, constant temperature fermentation and automatic sterilization parts are in the box body, and the electrical part is arranged on the upper part of the box body. The box body wall is made of two layers of metal sheets: an outer metal sheet 1 and an inner metal sheet 2, and a foaming material 3 as an insulating layer is filled between the inner and outer metal sheets. Foaming technology is used to realize the temperature isolation between the inside and outside of the box, so as to achieve the effect of energy saving and heat preservation. The door body of the cabinet is made of insulating glass, the outer layer is toughened gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com