Shock-absorbing device of block shaper

A technology for block forming machines and vibration damping devices, which is applied to ceramic forming machines, manufacturing tools, etc., and can solve problems such as short life of vibration motors, high energy consumption, and large mechanical losses of racks and vibration platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

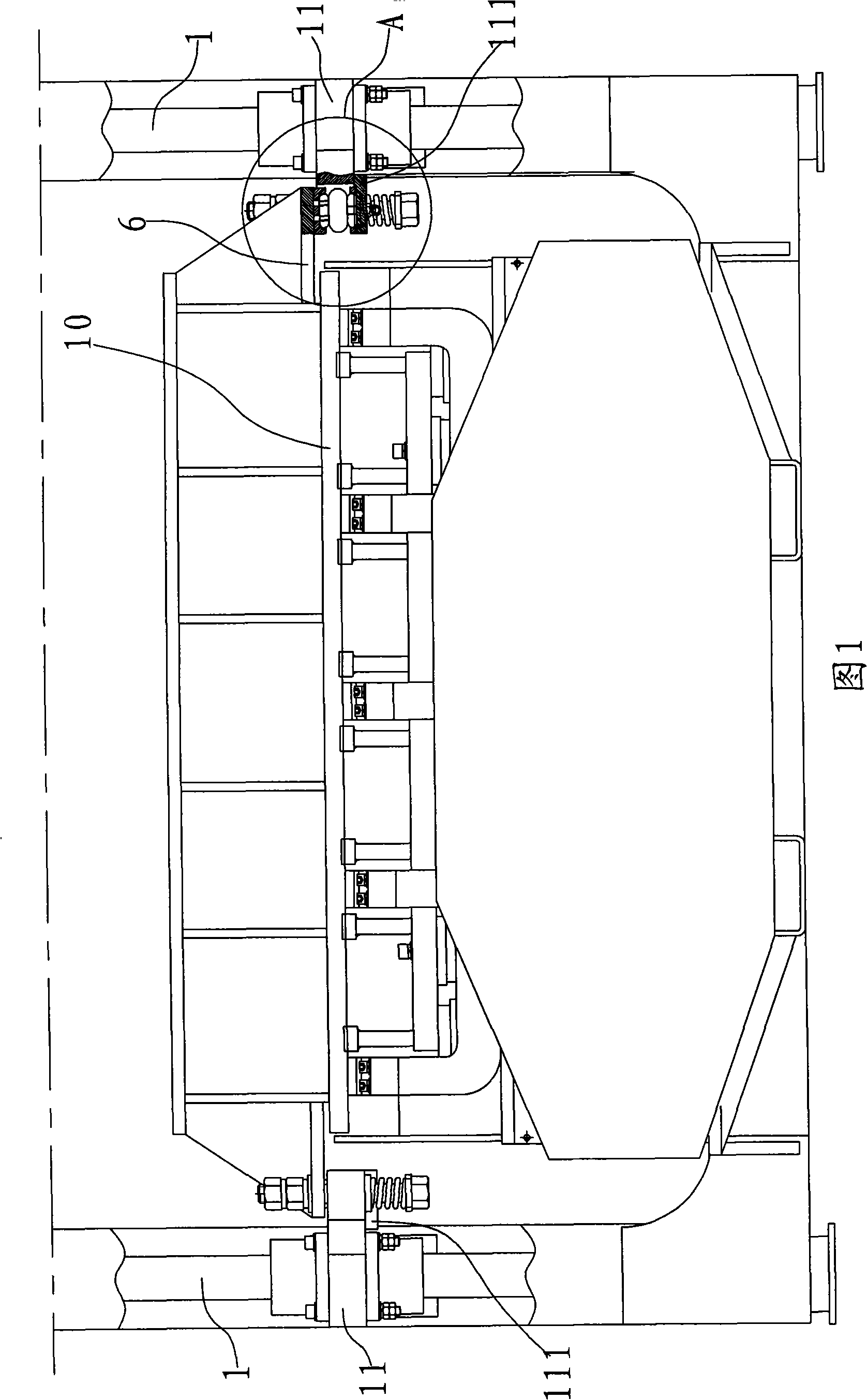

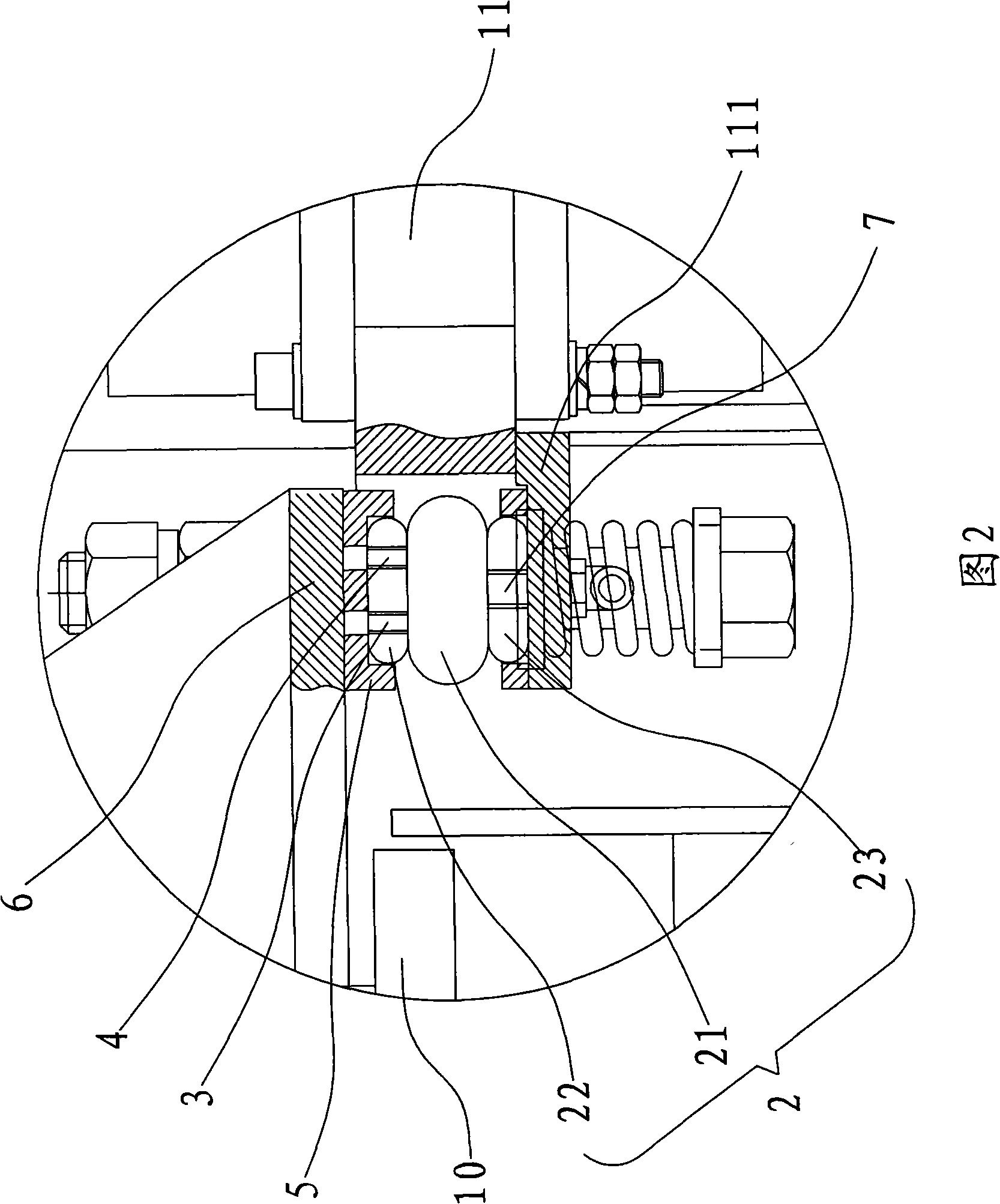

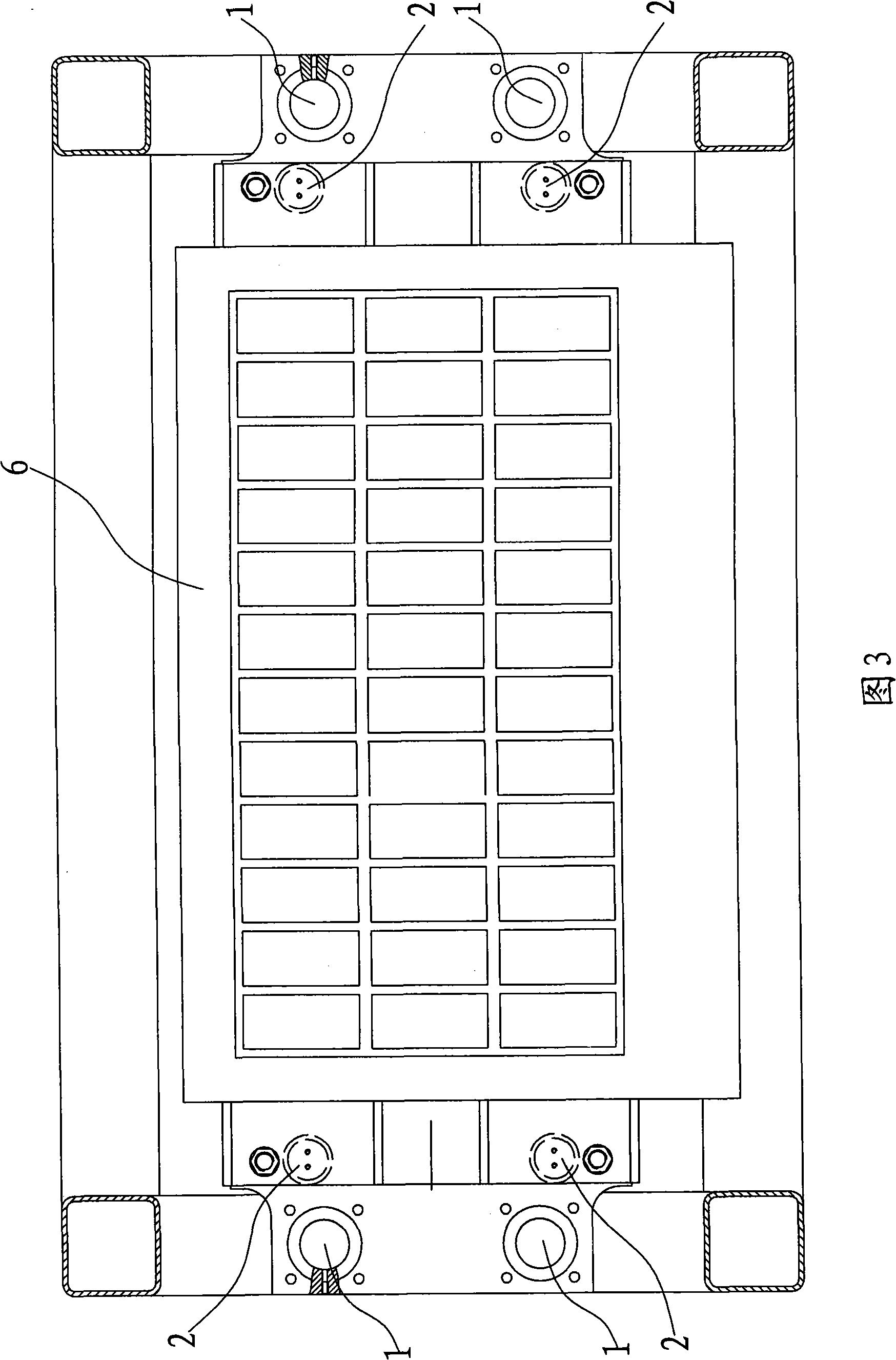

[0016] The vibration damping device of the block forming machine of the present invention, the first embodiment is shown in Figures 1, 2 and 3, the frame guide column 1 of the block forming machine is provided with a slide block 11, and the slide block 11 is provided with an extension 111, the airbag 2 includes an airbag body 21 and connecting parts 22, 23 connected to the upper and lower ends of the airbag body 21, the lower side of the mold 6 is provided with a briquetting block 5, and the connecting part 22 is connected to the mold through the bolts 3, 4 and the briquetting block 5 6 are locked together, and the connecting part 23 is locked together with the extension part 111 of the slider 11 through the bolt 7. In the present invention, the air bag 2 with an appropriate air pressure value can be selected according to the model of the block forming machine, and the air bag 2 can also be connected with an air pressure regulating device to meet the requirements of different m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com