Horizontal-seal cutting method for soft bag type package and horizontal-seal cutting device

A cutting device, soft bag technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as cleaning, debugging and adjustment troubles at unfavorable seals, clogging of knife grooves, etc., to prevent irreversible wrinkles , Improve the cutting quality and prevent the effect of sealing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

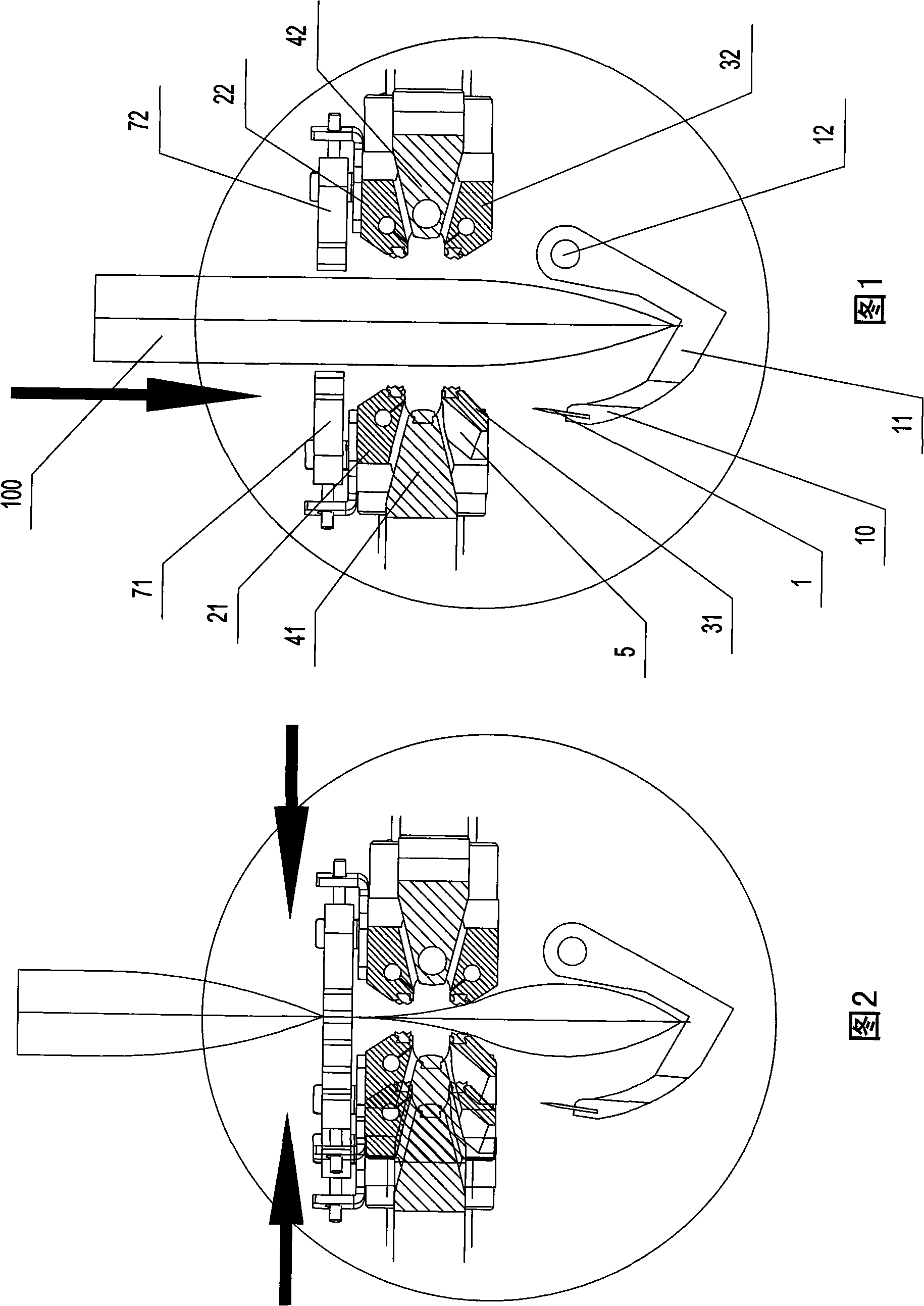

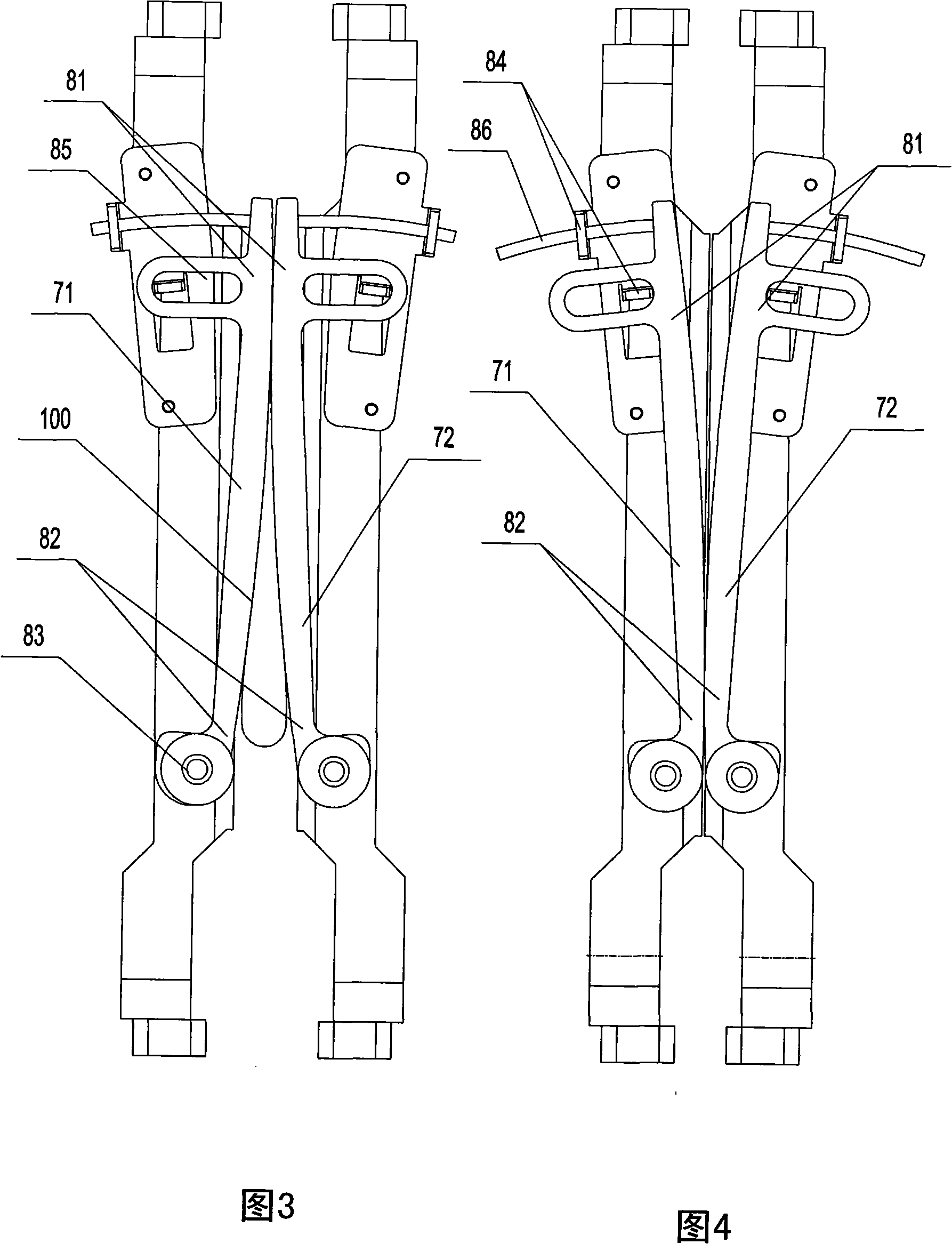

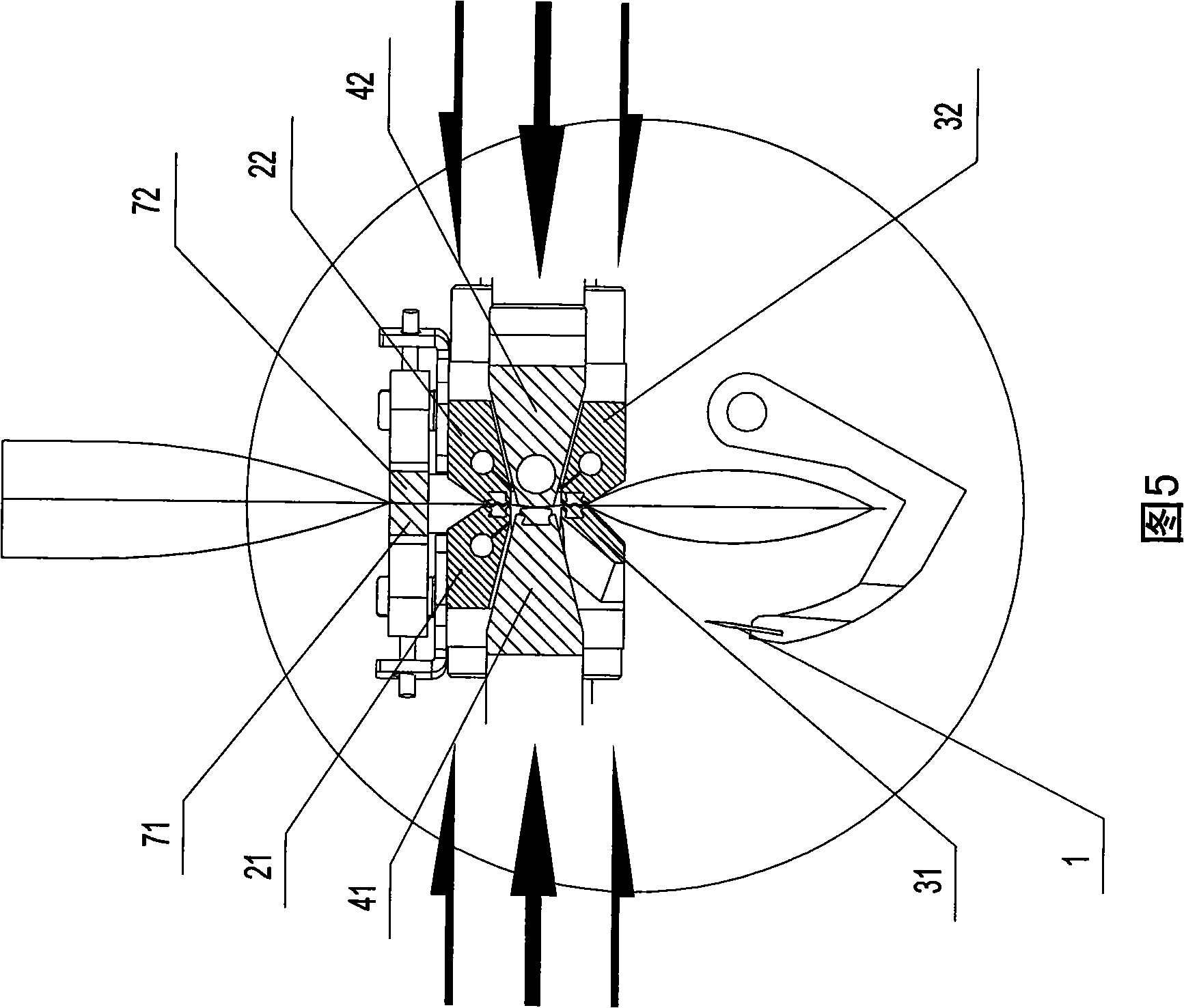

[0024] Referring to the accompanying drawings, firstly, the flexible bag packaging horizontal sealing and cutting device provided by the present invention will be introduced. It includes a clamping mechanism, a horizontal sealing heat-pressing mechanism, and a cutter 1. The clamping mechanism has a pair of upper clamping parts 21, 22 and a pair of lower clamping parts 31, 32, and is driven by a cam, a cylinder, etc. Drive it to move back and forth. When the forward movement is in place, the upper clamping film parts 21 and 22 clamp the packaging film above the horizontal sealing station, and the lower clamping film parts 31 and 32 clamp the packaging film below the horizontal sealing station. The front-rear direction refers to the movement direction of the applining membrane as the front, and vice versa as the rear, which is reflected in the left-right direction in the drawings.

[0025] Between the upper clamping film part and the lower clamping film part, a pair of working h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com