Tow mixing and matching filter tip rod

A technology of mixing and matching, filter rods, applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve the problems of lack of selectivity, reduce the adsorption of aroma components, and not take fiber into account, so as to improve the filtration efficiency and facilitate the retention , Conducive to the effect of fragrance ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

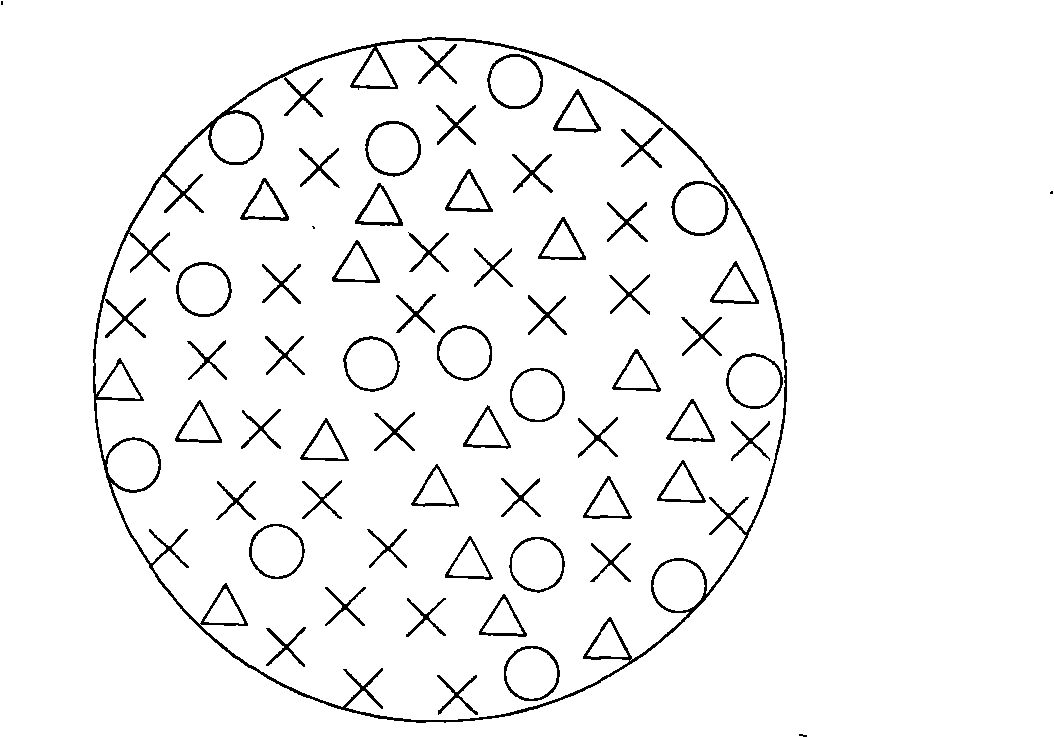

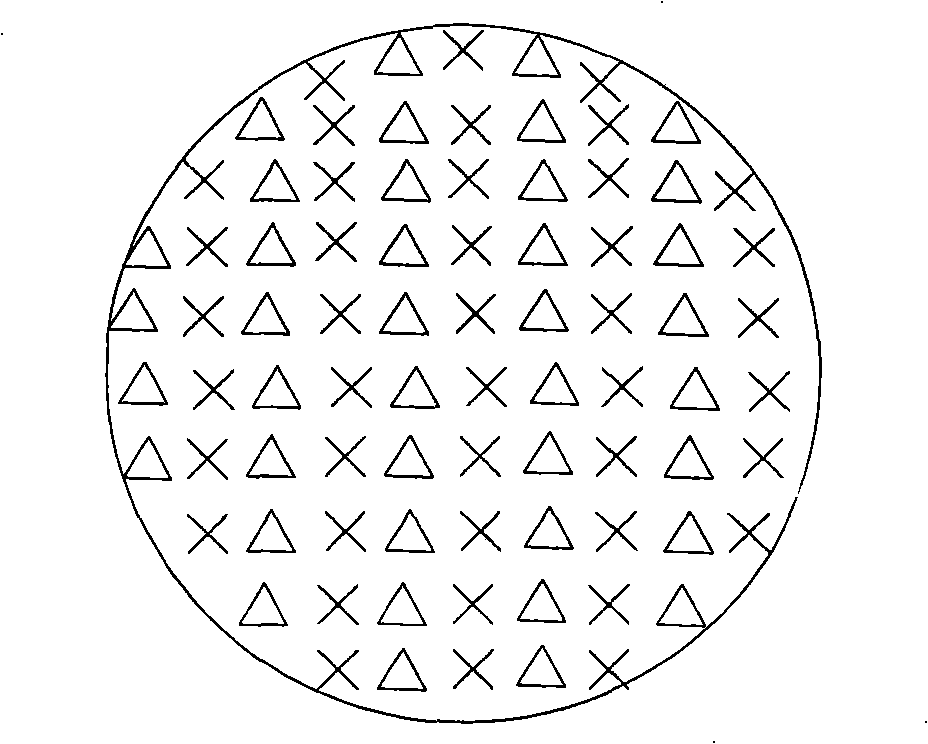

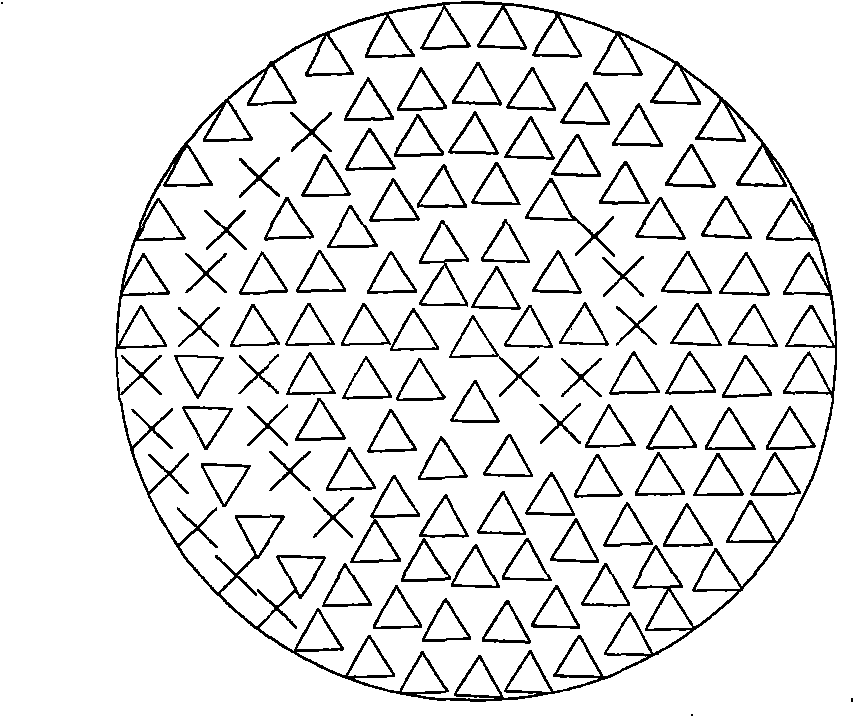

[0031] Three specifications of polypropylene fiber tows with monofilament linear densities of 2.0, 3.0, and 4.0 den were blended in proportions of 50%, 30%, and 20% respectively. The total density of the tows after blending was 25,000 den. The formed filter rod , the fiber distribution form is that the filter rod forms a linearly increasing distribution in the monofilament linear density along the axial center to the circumferential direction, and this tow filter rod is made into a cigarette filter rod according to the conventional filter rod forming process, and is applied to the cigarette Compared with the conventional polypropylene fiber filter rod cigarette with a tow specification of 2.7 / 25000, the cigarette can have a plump and harmonious aroma and reduce tar by 20%.

Embodiment 2

[0033] Seven specifications of polyacetate fiber tows with monofilament linear densities of 1.0, 2.0, 2.3, 3.3, 4.0, 5.0, and 6.0 den were respectively divided into 30%, 20%, 10%, 10%, 10%, 10%, and 10%. The ratio of blending is carried out. The total density of the tow after blending is 45000den. After forming the filter rod, the fiber distribution form is that the filter rod forms a linearly increasing distribution on the linear density of the single filament along the axial center to the circumferential direction. The bundle filter rod is made into a cigarette filter rod according to the conventional filter rod forming process, and is applied to the cigarette. Compared with the conventional cellulose acetate filter rod cigarette with the tow specification of 2.76 / 45000, it can make the aroma of the cigarette rich, elegant and mellow. The miscellaneous gas is light, the taste is comfortable, and the tar is reduced by 56%, and the moisture is increased by 25%.

Embodiment 3

[0035] Three specifications of polyacetate fiber tows with monofilament linear densities of 2.0, 3.0, and 4.0 den were blended at a ratio of 30%, 50%, and 20%, respectively. The total density of the tows after blending was 35,000 den. The formed filter rod , the fiber distribution form is that the filter rod forms a linearly decreasing distribution in the monofilament linear density along the axial center to the circumferential direction, and this tow filter rod is made into a cigarette filter rod according to a conventional filter rod forming process, and is applied to a cigarette Compared with conventional cellulose acetate filter plug cigarettes with a tow specification of 2.9 / 35000, it can make the aroma of the cigarette plump and mellow, reduce tar by 40% and increase moisture by 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com