Food and drug industry protective boots and boots producing method and boots technical criterion

A technology for the pharmaceutical industry and production method, which is applied to the production of protective boots and boots in the food and pharmaceutical industries and the technical standards of boots, can solve problems such as unfavorable industrial development and technological progress, affecting protection functions, and inability to guarantee supervision and management, etc. Achieve the effect of protecting human health and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

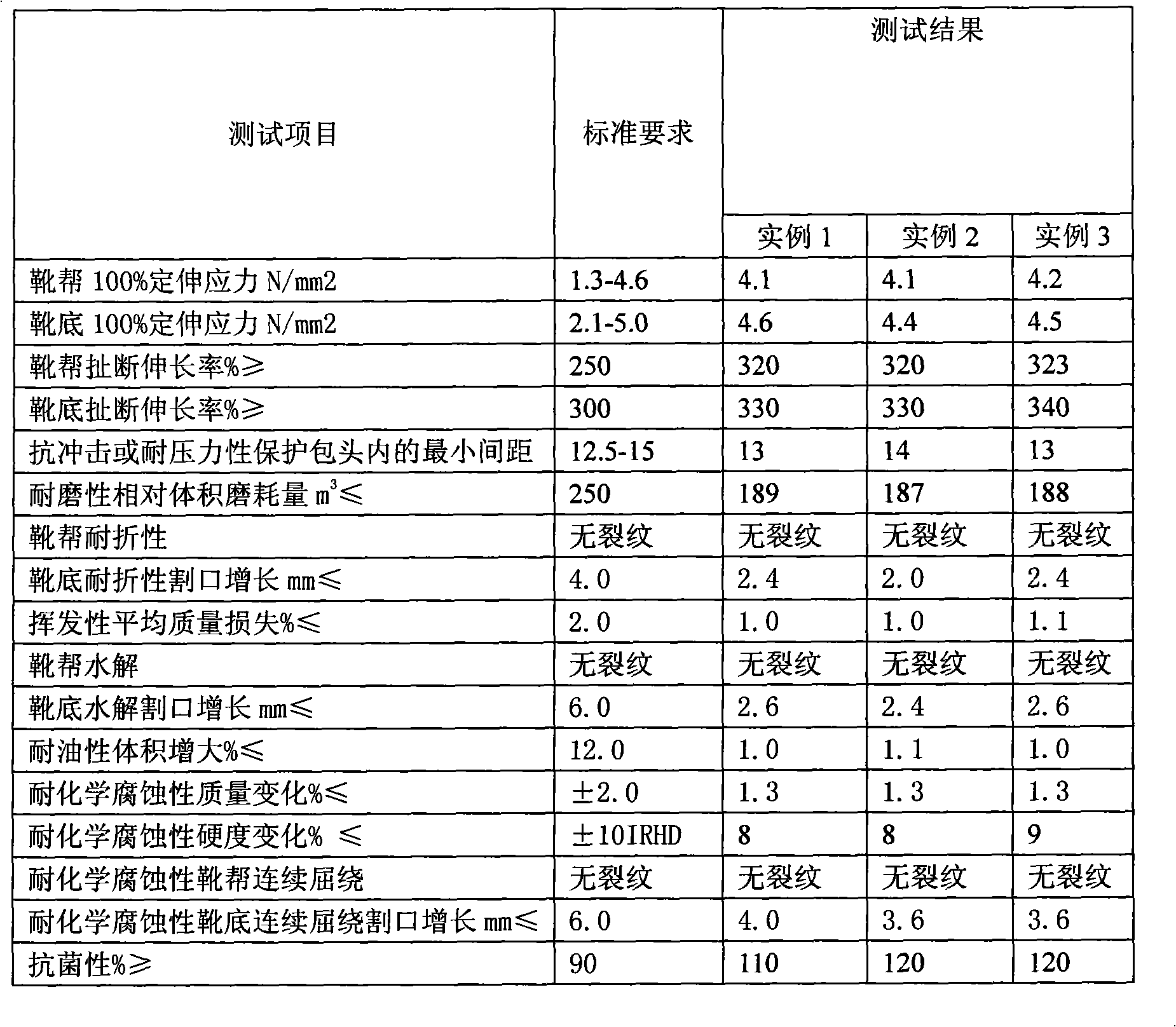

Examples

example 1

[0034] Example 1: First, take the weight of the upper and the bottom of the boot according to the composition as follows:

[0035] Boot sole

[0036] Polyvinyl chloride-PVC-S-1000 51.0% 51.2%

[0037] Dioctyl phthalate-DOP 30.6% 26.1%

[0038] Polyester Plasticizer-GLOBZNEX-2340-S 15.3% 19.1%

[0039] Composite rare earth stabilizer 2.1% 2.5%

[0040] Inorganic silver-based antibacterial agent 1.0% 1.2%

[0041] Then, the plastic granules of the boot upper and the sole are produced separately. The plastic granules are produced by the following specific steps: ①Dioctyl phthalate-DOP and polyester plasticizer-GLOBINEX-2340-S are blended in a mixer and pre-mixed. Heat to 50°C and set aside; ②Add other components together to a high-speed mixer and stir at a low speed for 2 minutes, mix thoroughly and mix well at a speed of 750 rpm; ③Add the pretreated plasticizer to a high-speed mixer and stir at a low speed for 15 minutes, The speed is 750 rpm;...

example 2

[0043] Example 2: First, take the weight of the upper and the sole of the boot according to the composition as follows:

[0044] Boot sole

[0045] Polyvinyl chloride-PVC-S-1000 51.0% 51.2%

[0046]Dioctyl phthalate-DOP 30.6% 26.1%

[0047] Polyester Plasticizer-GLOBZNEX-2340-S 15.3% 19.1%

[0048] Composite rare earth stabilizer 2.1% 2.5%

[0049] Inorganic silver-based antibacterial agent 1.0% 1.2%

[0050] Then, the plastic granules of the boot upper and the sole are produced separately. The plastic granules are produced by the following specific steps: ①Dioctyl phthalate-DOP and polyester plasticizer-GLOBINEX-2340-S are blended in a mixer and pre-mixed. Heat to 60°C and set aside; ② Add other components together to a high-speed mixer and stir at a low speed for 2 minutes, mix thoroughly and mix well at a speed of 770 rpm; ③ Add the pretreated plasticizer to a high-speed mixer and stir at a low speed for 18 minutes, The speed is 770 rpm;...

example 3

[0052] Example 3: First, weigh the upper and sole of the boot according to the composition as follows:

[0053] Boot sole

[0054] Polyvinyl chloride-PVC-S-1000 51.0% 51.2%

[0055] Dioctyl phthalate-DOP 30.6% 26.1%

[0056] Polyester Plasticizer-GLOBZNEX-2340-S 15.3% 19.1%

[0057] Composite rare earth stabilizer 2.1% 2.5%

[0058] Inorganic silver-based antibacterial agent 1.0% 1.2%

[0059] Then, plastic granules for boot uppers and soles are produced respectively. The production of plastic granules consists of the following specific steps: ①Dioctyl phthalate-DOP and polyester plasticizer-GLOBINEX-2340-S are mixed in a mixer and preheated to 70°C for use; ② Add other components together to a high-speed mixer and stir at a low speed for 5 minutes, mix thoroughly and mix well, and the speed is 790 rpm; ③ Add the pretreated plasticizer to the high-speed mixer and stir at a low speed for 20 minutes. 790 rev / min; ④ Stir the material at a low s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com