Portable atmospheric pressure plasma cleaner

A constant voltage, portable technology, applied in the field of cleaning devices, can solve the problems of electrode surface erosion, short plasma life, unsafe human body and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The objects and advantages of the present invention will be illustrated by the following detailed description of the embodiments and accompanying drawings.

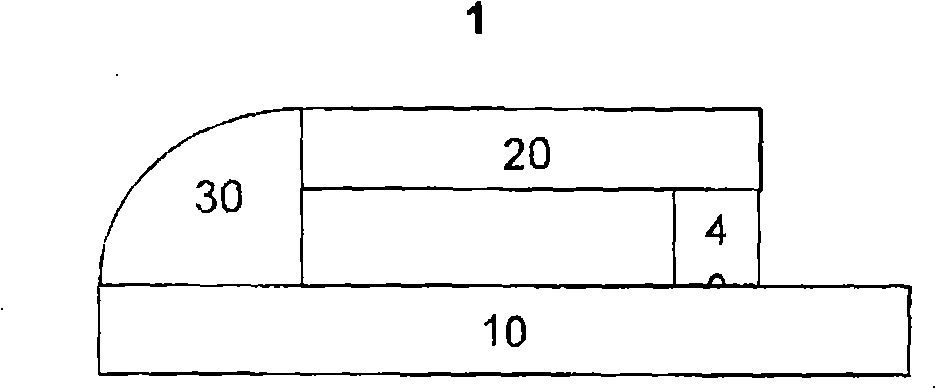

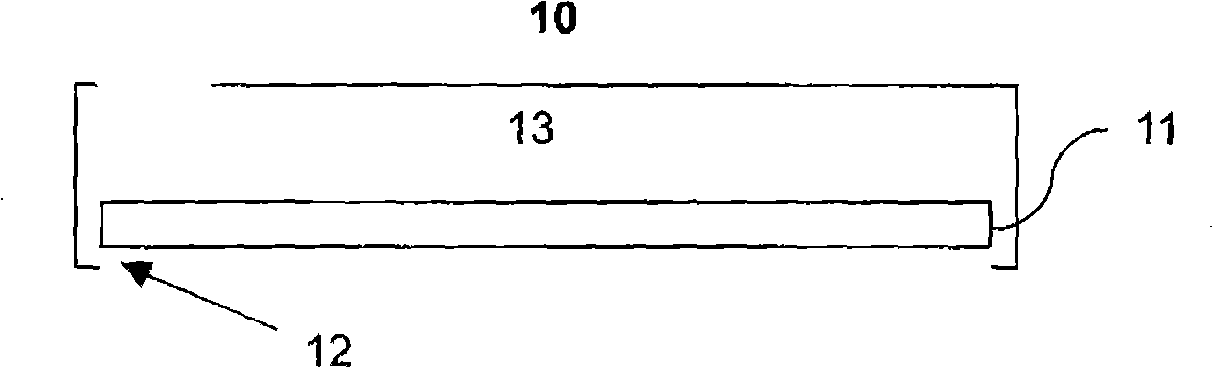

[0029] see Figure 1-7 , the present invention is a portable atmospheric plasma cleaning machine 1, which is a hand-held device for cleaning glass and glass coating materials. It mainly includes an electrode system 11 and a water and air supply module 30; Household power generates a plasma layer; the water and air supply module 30 integrates a water storage tank 32 and an air flow channel 31 and uses a small atomizer 33 to mix water and air.

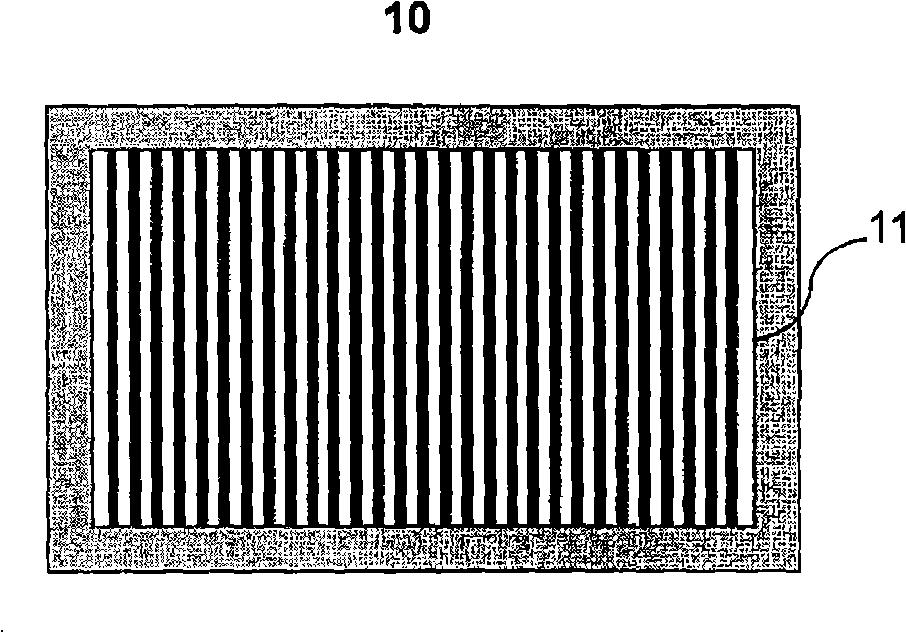

[0030] The electrode system 11 is composed of a dielectric material 112 and a certain number of conductive electrodes 111 embedded in the dielectric material 112; the dielectric material 112 is a ceramic or glass substrate; the distance between the electrodes 111 is between 0.05 mm and 5 mm , and the working distance between the dielectric material 112 and the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com