Method for producing first-grade metallurgical coke using high-sulfur and high-ash coking coal

A technology for metallurgical coke and coking coal, applied in the production field of primary metallurgical coke, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

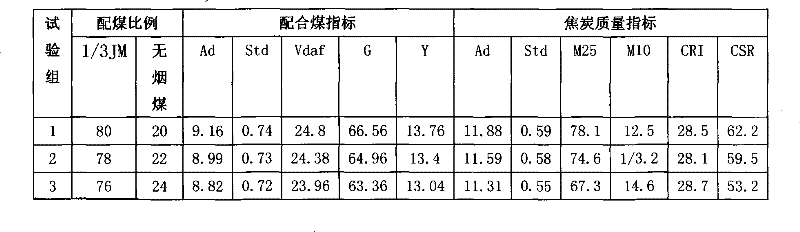

Method used

Image

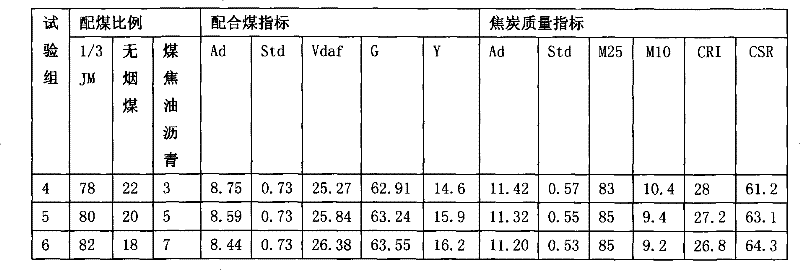

Examples

Embodiment 1

[0037] 1. Coal blending: According to the weight ratio, 1 / 3JM: anthracite: coal tar pitch is 78:22:3;

[0038] The coal blending accuracy reaches 98.45%;

[0039] 2. Cooperate with coal fineness and crushing method:

[0040] The coal fineness below 3mm accounts for 92%;

[0041] The process of breaking first and then mixing is adopted. 1 / 3JM is easy to be broken, and the first-level crushing method is adopted. Anthracite adopts a three-stage crushing method, that is, pre-crushing, preliminary adjustment of particle size, then entering the coal blending tank, using a special hard coal crusher for fine crushing, and finally entering the final crusher together with coking coal for the third crushing.

[0042] 3. With coal moisture: 10% by weight.

[0043] 4. Mixing of bitumen: When stored in summer, it will soften and agglomerate, which will affect coal extraction and coal blending operations. The solution is to pre-mix bitumen with a small amount of coal and store it as a coal type, and ...

Embodiment 2

[0050] 1. Coal blending: according to the weight ratio, 1 / 3JM: anthracite: coal tar pitch is 80:20:5;

[0051] The coal blending accuracy reaches 98.50%;

[0052] 2. Cooperate with coal fineness control and crushing method:

[0053] The coal fineness below 3mm accounts for 93%;

[0054] 3. The coal moisture is 11% by weight;

[0055] 4. Tamping: the density of briquettes reaches 1.03;

[0056] The other processes are the same as in the first embodiment.

[0057] The obtained coke indicators are as follows:

[0058] Analysis Project Ad Std M40 M25 M10 CRI CSR index 11.20 0.53 86.5 92.5 5.8 26 63

[0059] It can be seen from the above table that the coke fully meets the national first-level metallurgical coke standard, and its strength index and thermal performance index are better than the first-level metallurgical coke standard.

Embodiment 3

[0061] 1. Coal blending: 1 / 3JM: anthracite: coal tar pitch in parts by weight 82:18:7;

[0062] The coal blending accuracy reaches 98.90%;

[0063] 2. Cooperate with coal fineness control:

[0064] The coal fineness below 3mm accounts for 95%;

[0065] 3. The moisture content of the coal is 11% by weight;

[0066] 4. Tamping: the density of briquettes reaches 1.05;

[0067] The other processes are the same as in the first embodiment.

[0068] The obtained coke indicators are as follows:

[0069] Analysis Project Ad Std M40 M25 M10 CRI CSR index 11.53 0.56 87 92.5 5.8 26 63

[0070] It can be seen from the above table that the coke fully meets the national first-level metallurgical coke standard, and its strength index and thermal performance index are better than the first-level metallurgical coke standard.

[0071] Fat coal is also a kind of high-sulfur and high-ash coal. Its characteristic is that the sulfur index is higher than 1 / 3JM, and other indexes are better than 1 / 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com