Dechlorination process from zinc electrolytic solution

A zinc electrolysis and solution technology, applied in the field of hydrometallurgy, can solve the problems of high zinc loss rate, large copper excess coefficient, difficult process control, etc., and achieve the effect of eliminating high cost

Active Publication Date: 2008-10-15

YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

View PDF0 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Obviously, due to the above several reasons, the copper slag dechlorination method has a large excess coefficient of copper, a large amount of feed, a large amount of slag, a high zinc loss rate, and the regeneration and recycling of copper slag is difficult, and the process is difficult to control.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

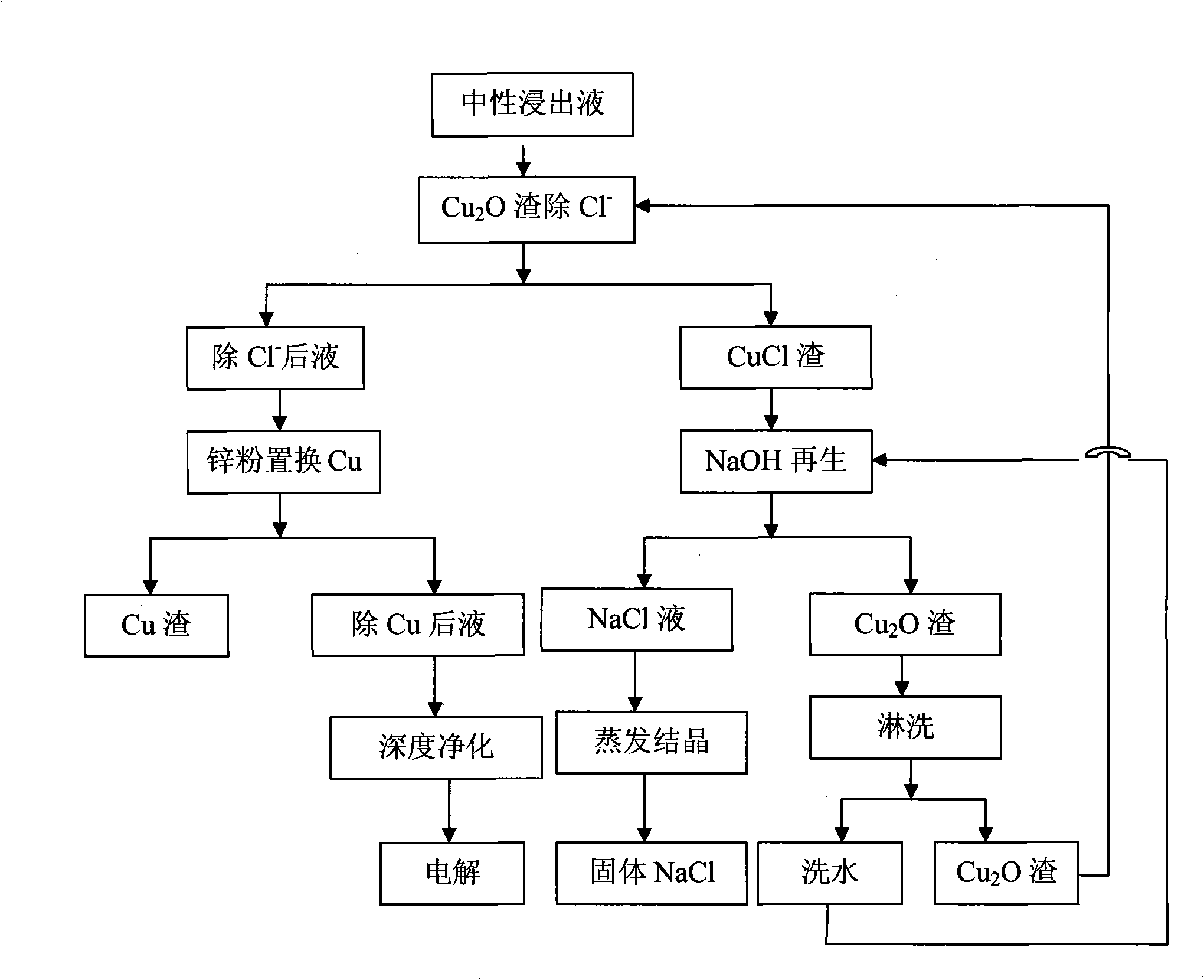

Login to View More Abstract

The invention relates to a dechlorination method for zinc electrolytic solution, in particular to a dechlorination method for high concentration chloridion neutral lixivium of zinc hydrometallurgy. The method comprises the following steps that: the zinc electrolytic neutral lixivium with chloridion is in the dilute sulphuric acid condition with Cu2O and pH value of between 2.0 and 3.5, obtained Cu2SO4 through dissolving and Cl-1 react to obtain CuCl precipitate which is difficult to dissolve; CuCl is separated and then reacts with alkaline solution to obtain Cu2O which can be circularly used; and the chloride becomes solid chloride through evaporating and crystallizing. The dechlorination method for zinc electrolytic solution has the advantages of low technological cost, high efficiency, high extraction yield of regenerant and easy operation.

Description

A method for removing chlorine in zinc electrolytic solution technical field The invention relates to a process for dechlorinating the neutral leachate when the chlorine ion concentration of the neutral leachate is relatively high during the zinc electrolysis process, which belongs to the hydrometallurgical technology. Background technique In the field of zinc hydrometallurgy, the dechlorination process of neutral leachate has been mainly adopted for a long time: silver chloride precipitation method and copper slag dechlorination method. 1. Silver chloride precipitation method: Reaction formula: Ag2SO4+2Cl-=SO4 2-+2AgCl↓ Although this method is effective in removing chlorine, it is economically unreasonable because the silver salt is expensive, and the actual yield of silver regeneration is low, and the cost is high. 2. Copper slag dechlorination method: Reaction formula: Cu+Cu2++2Cl-=2CuCl↓ This method mainly uses elemental copper and copper ions (Cu2+) to inter...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B3/46

CPCY02P10/20

Inventor 罗玉德

Owner YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com