Fuel economizing device

A technology of fuel oil and shell, applied in the direction of combustion method, liquid fuel supply/distribution, etc., can solve the problems of no discovery, not belonging to fuel saving, etc., and achieve the goal of increasing the number of molecules, fine and uniform oil droplets, and increasing the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

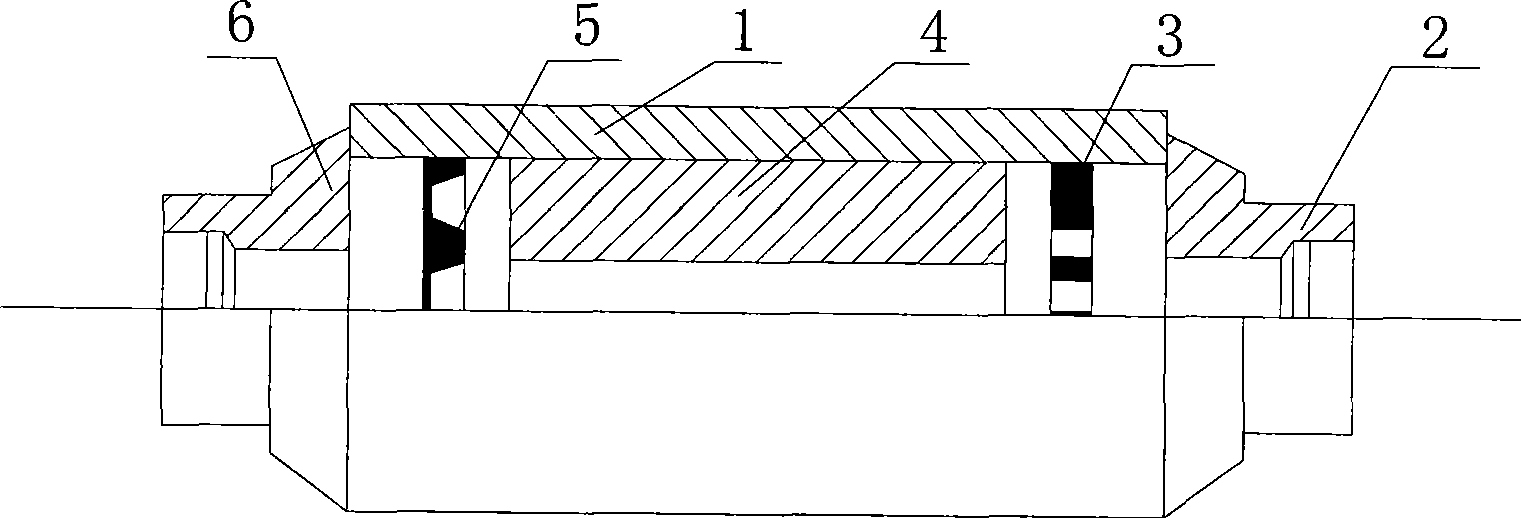

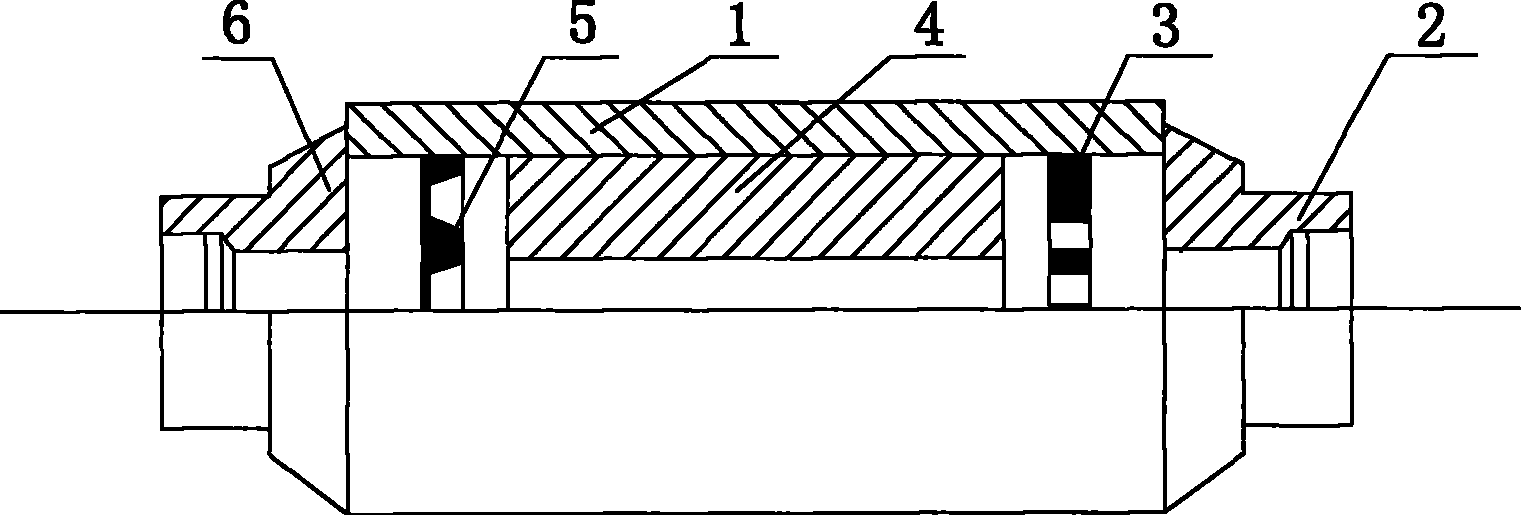

Image

Examples

Embodiment 1

[0020] Embodiment 1: The fuel oil-saving device of the present invention is used in an oil-fired boiler of an enterprise, wherein the elements and weight percentages included in the precious metallized sheet are: platinum 0.66%, ruthenium 0.041%, and the balance is copper; the precious metal catalytic sheet Included elements and percentages by weight are 0.17% rhodium, 0.09% palladium, and the balance is copper. After testing, the fuel saving efficiency reaches 8.8%.

Embodiment 2

[0021] Embodiment 2: The fuel-saving device of the present invention is used in a certain large diesel engine, wherein the elements and weight percentages included in the precious metallized sheet are: platinum 0.6%, ruthenium 0.09%, and the balance is copper; the precious metal catalytic sheet Included elements and percentages by weight are 0.37% rhodium, 0.11% palladium, and the balance is copper. After testing, the fuel saving efficiency reaches 7.55%.

Embodiment 3

[0022] Embodiment three: the fuel oil-saving device of the present invention is used in a certain hotel boiler, wherein the elements and weight percentages included in the precious metallized sheet are: platinum 0.6%, ruthenium 0.09%, and the balance is copper; the precious metal catalytic sheet includes The elements and weight percentages are rhodium 0.5%, palladium 0.19%, and the balance is copper. After testing, the fuel saving efficiency reaches 14.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com