Rare earth metal methane catalyst and preparation method thereof

A rare earth metal and catalyst technology, applied in the field of catalyst and its preparation, can solve the problems of easy volatilization and decomposition, catalyst deactivation, industrialization restrictions, etc., and achieve the effect of low cost, high combustion activity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

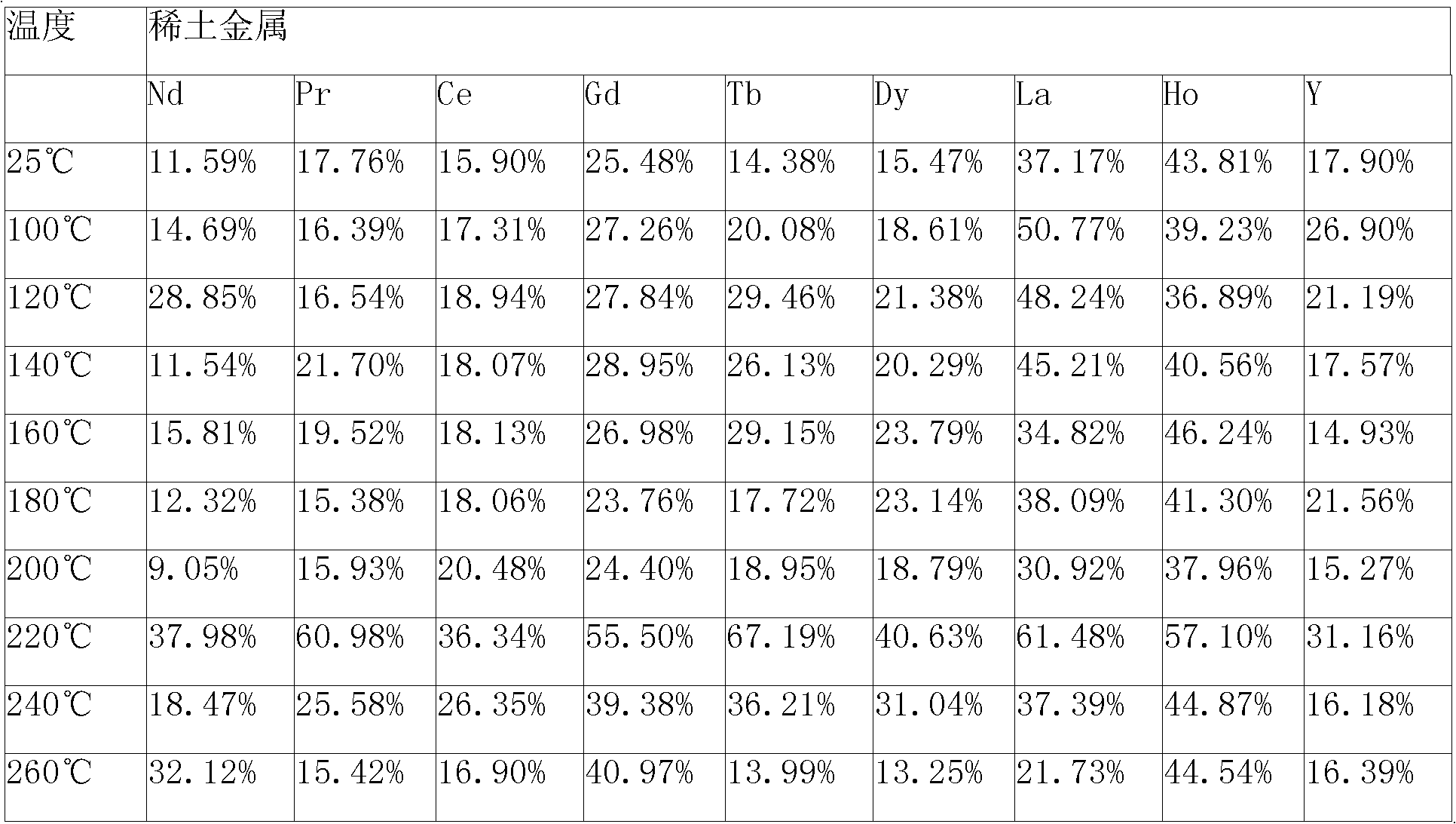

[0011] Specific embodiment one: in this embodiment, the rare earth metal methane catalyst is made of palladium nitrate, rare earth metal, dilute nitric acid and carrier with a mass concentration of 1% to 3%, and the mass ratio of rare earth metal to palladium nitrate is 1.5 to 2.5:1 , the mass ratio of the rare earth metal to the carrier is 1:2.5-3.0, and the mass ratio of palladium nitrate to dilute nitric acid is 1g:50mL.

[0012] The rare earth metal methane catalyst described in this embodiment is sealed and stored.

[0013] In this embodiment, part of the palladium is replaced by rare earth metals, so the cost is greatly reduced.

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment is different from Embodiment 1 in that: the mass ratio of the rare earth metal to palladium nitrate is 2:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the mass ratio of the rare earth metal to the carrier is 1:2.85. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com