Method for coating DPF with sandwich type catalyst coating, obtained product and application

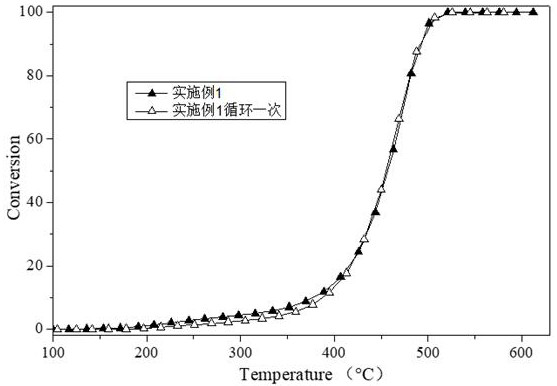

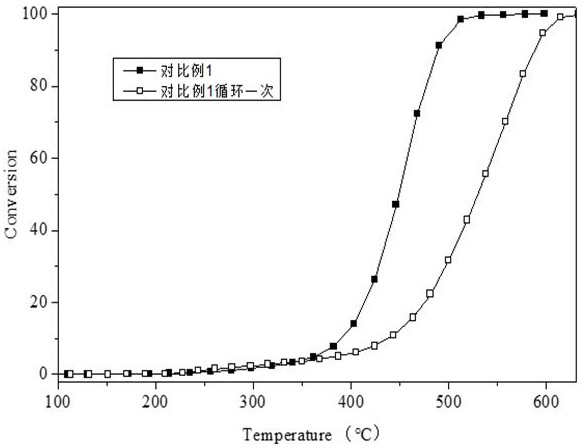

A catalyst coating, sandwich-type technology, applied in the direction of chemical instruments and methods, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problems of easy loss and potassium loss, and achieve improved combustion activity, high activity and Effect of stability, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for coating a sandwich-type catalyst coating on a DPF, the specific steps of which are:

[0050] a. First weigh 4.0 g of cerium-based composite oxide (CeO 2 : ZrO 2 : La 2 o 3 : Nd 2 o 3 (mass ratio = 80:80:50:50) was added to 100 ml of deionized water, stirred for 2 h and then ball-milled for 9 h to obtain a suspension with an average particle size of 390 nm, and continued to stir for 1.5 h; weighed 0.07 g of carboxyl Sodium methylcellulose was dissolved in 10 mL of deionized water, mixed with the cerium-based composite oxide suspension, and stirred for 2 h to obtain the slurry of the first coating; according to the coating amount of the active component 8 g / L , the slurry of the first coating was quantitatively and uniformly coated on the cordierite honeycomb ceramic carrier; the coated cordierite honeycomb ceramic carrier was dried at 70 °C for 5 h, and then transferred to an oven at 110 °C Dry for 5 h. A cordierite honeycomb ceramic carrier coated wi...

Embodiment 2

[0054] A method for coating a sandwich-type catalyst coating on a DPF, the specific steps of which are:

[0055] a. First weigh 4.0 g of cerium-based composite oxide (CeO 2 : ZrO 2 : La 2 o 3 : Y 2 o 3 (mass ratio=20:80:13:13) was added to 190 mL deionized water, stirred for 2 h and ball milled for 6 h to obtain a suspension with an average particle size of 430 nm; weigh 0.05 g sodium carboxymethyl cellulose to dissolve In 10 mL of deionized water, mixed with the cerium-based composite oxide suspension, and continued to stir for 2.5 hours to obtain the slurry of the first coating; according to the coating amount of the active component 8 g / L, the prepared second coating The slurry of the first coating was quantitatively and evenly coated on the cordierite honeycomb ceramic carrier; the coated cordierite honeycomb ceramic carrier was dried at 70 °C for 5 h, and then transferred to an oven at 110 °C for 5 h. A cordierite honeycomb ceramic carrier coated with the first laye...

Embodiment 3

[0059] A method for coating a sandwich-type catalyst coating on a DPF, the specific steps of which are:

[0060] a. First weigh 6.0 g of cerium-based composite oxide (CeO 2 : PrO 2 : ZrO 2 : La 2 o 3 : Nd 2 o 3 : Y 2 o 3 mass ratio=80:50:80:50:50:13) into 100 mL of deionized water, stirred for 3 h and ball milled for 12 h to obtain a suspension with an average particle size of 380 nm; weigh 0.5 g of carboxymethyl Sodium cellulose was dissolved in 10 mL of deionized water, mixed with the cerium-based composite oxide suspension, and stirred for 3 h to obtain the slurry of the first coating; according to the coating amount of the active component 5 g / L, the prepared The slurry of the first coating was quantitatively coated on the cordierite carrier; the coated cordierite carrier was dried at 90 °C for 1 h, and then transferred to an oven at 100 °C for 10 h. A cordierite carrier coated with the first layer of coating is obtained.

[0061] b. First weigh 6.0 g of cerium-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com