Petrochemical fuel oil normal-temperature cracking hydrogen-rich device

A catalytic cracking and fuel oil technology, applied in the petroleum industry, catalytic cracking, cracking, etc., can solve the problems that hydrogen-rich combustion cannot be widely used, the dehydrogenation process is complicated and difficult to control, and the transportation and storage risks are high, and it can expand the lean burn limit. Range, reliable handling, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

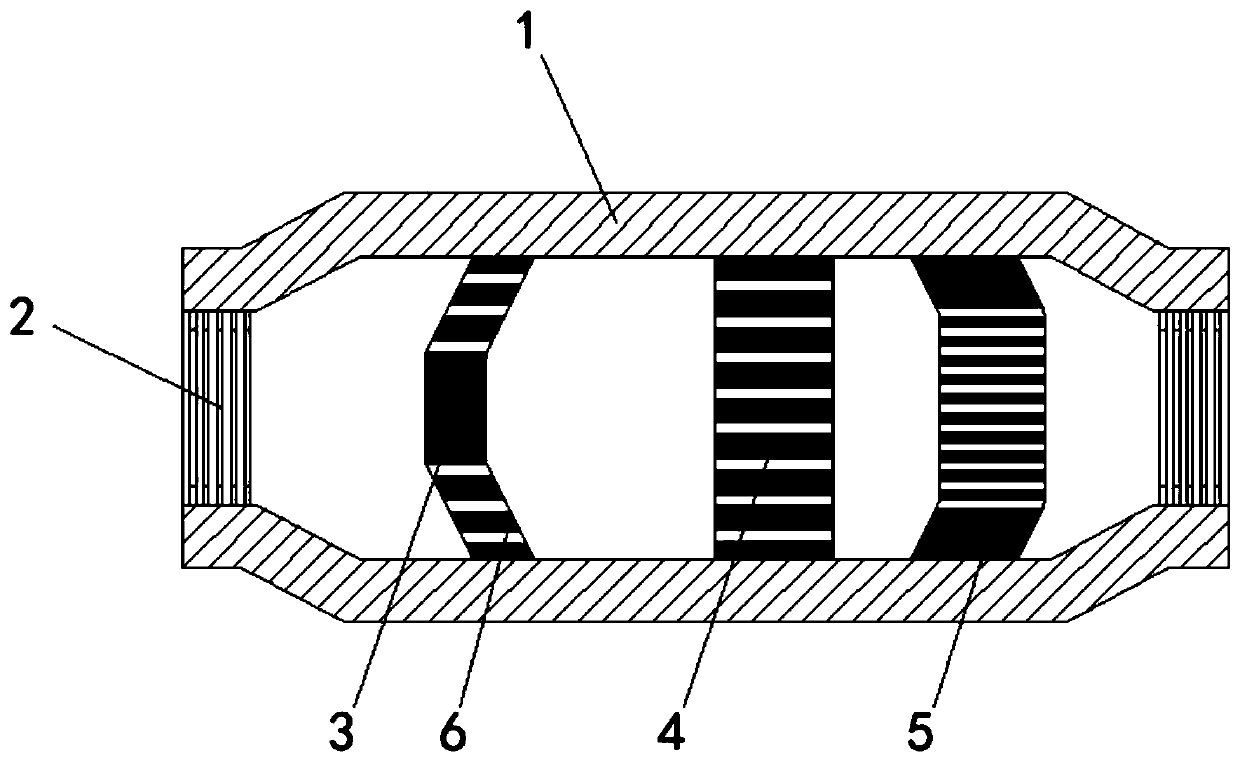

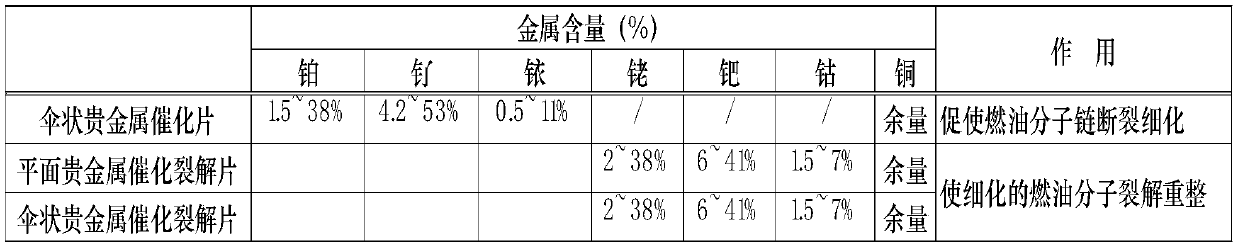

Embodiment 1

[0021] The device of the present invention is used in two 8T / H fuel oil (diesel) boilers in a tertiary hospital. Among them, the elements and mass proportions included in the umbrella-shaped precious metal catalytic piece 3 are respectively: 26% platinum, 39% ruthenium, 7% iridium, and the balance is copper; the planar precious metal catalytic cracking piece 4 and the umbrella-shaped precious metal catalytic cracking piece 5 include The elements and mass proportions are respectively rhodium 28%, palladium 38%, cobalt 4%, and the balance is copper. Test and set the device of the present invention: 1. Automatically feed water to the high water level, and the water pump automatically stops; 2. Set the steam pressure to 12 kg, record the numbers of the oil inlet meter and the oil return meter, and then turn on the automatic combustion mode to boost the pressure When the weight reaches 12 kg, the boiler will automatically shut down. The purpose is to observe the change of combusti...

Embodiment 2

[0023] The device of the present invention is used in three 4T / H oil-fired boilers (diesel) in a five-star hotel. Among them, the elements and mass proportions included in the umbrella-shaped precious metal catalytic piece 3 are respectively: 26% platinum, 39% ruthenium, 7% iridium, and the balance is copper; the planar precious metal catalytic cracking piece 4 and the umbrella-shaped precious metal catalytic cracking piece 5 include The elements and mass proportions are respectively rhodium 28%, palladium 38%, cobalt 4%, and the balance is copper. Tested at an ambient temperature of 25°C, the fuel-saving rate reached 7.4%, and the fuel cost of using traditional fuel devices dropped by more than 900,000 yuan after 5 months of operation. It was rated as the first batch of green hotels that year. (The comparison test method is the same as that of a certain hospital, and the comparison is made with reference to the fuel consumption at the same time period in previous years).

Embodiment 3

[0025] The device of the present invention is used on a 30-ton large truck of a certain large-scale logistics company in Shanghai, and the power of the diesel engine is 330kw (for a high-pressure common rail technology engine). Among them, the elements and mass ratios included in the umbrella-shaped precious metal catalytic piece 3 are: platinum 19%, ruthenium 39%, iridium 8%, and the balance is copper; the planar precious metal catalytic cracking piece 4 and the umbrella-shaped precious metal catalytic cracking piece 5 include The elements and mass proportions are respectively 22% rhodium, 38% palladium, 5% cobalt, and the balance is copper. The test plan is formulated by the logistics company. The ambient temperature is -3°C, and the test is performed at idle speed. There is a spare electronic weighing scale with an accuracy of 0.1%, and a plastic open oil drum with a capacity of 100 liters. Implementation of the test plan: park in neutral, set the speed at 800, and run at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com