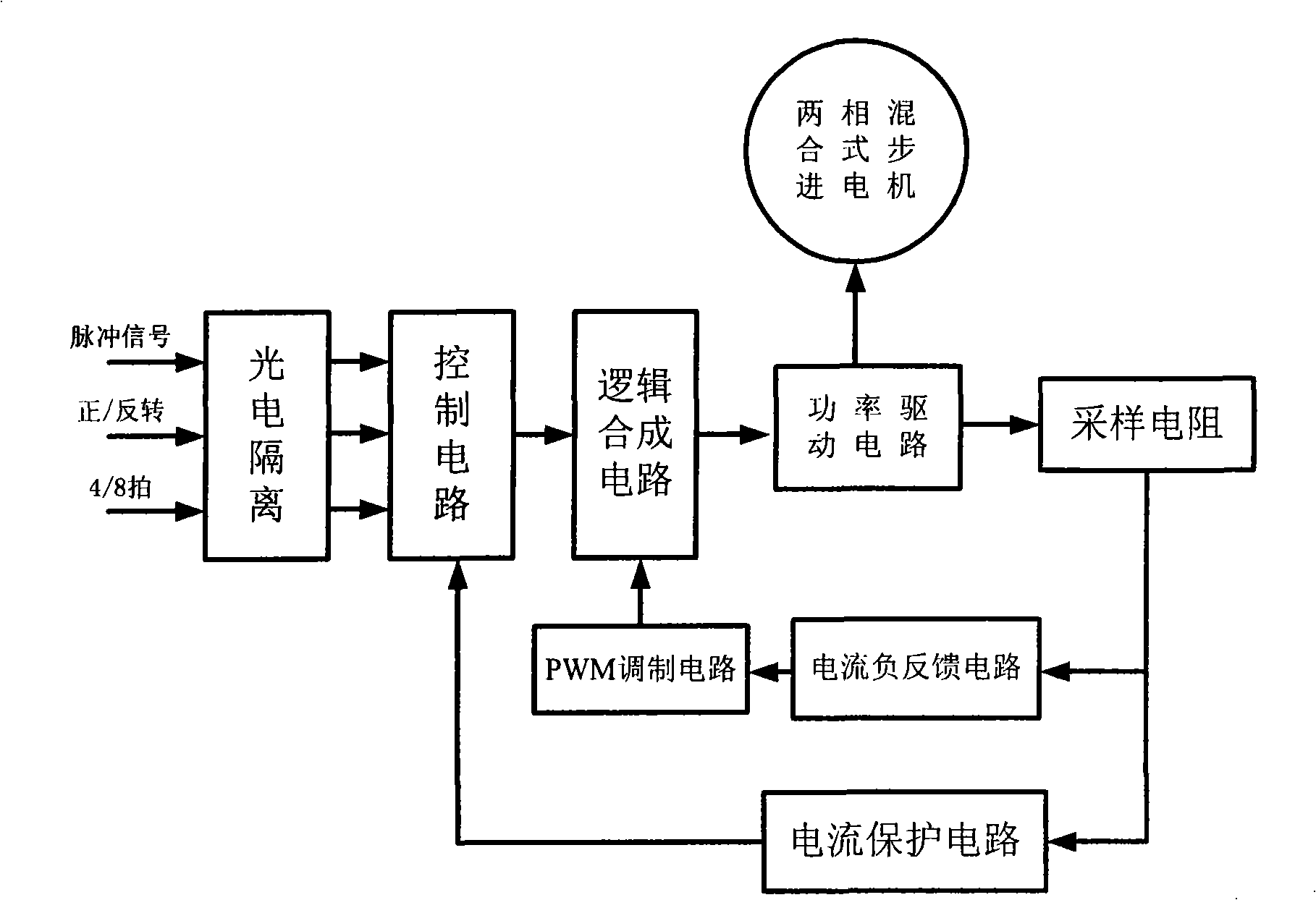

Driving system of stepping motor with current negative feedback

A technology of current negative feedback and stepping motors, which is applied in the direction of motor generator control, control systems, electrical components, etc., and can solve problems such as increasing circuit complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

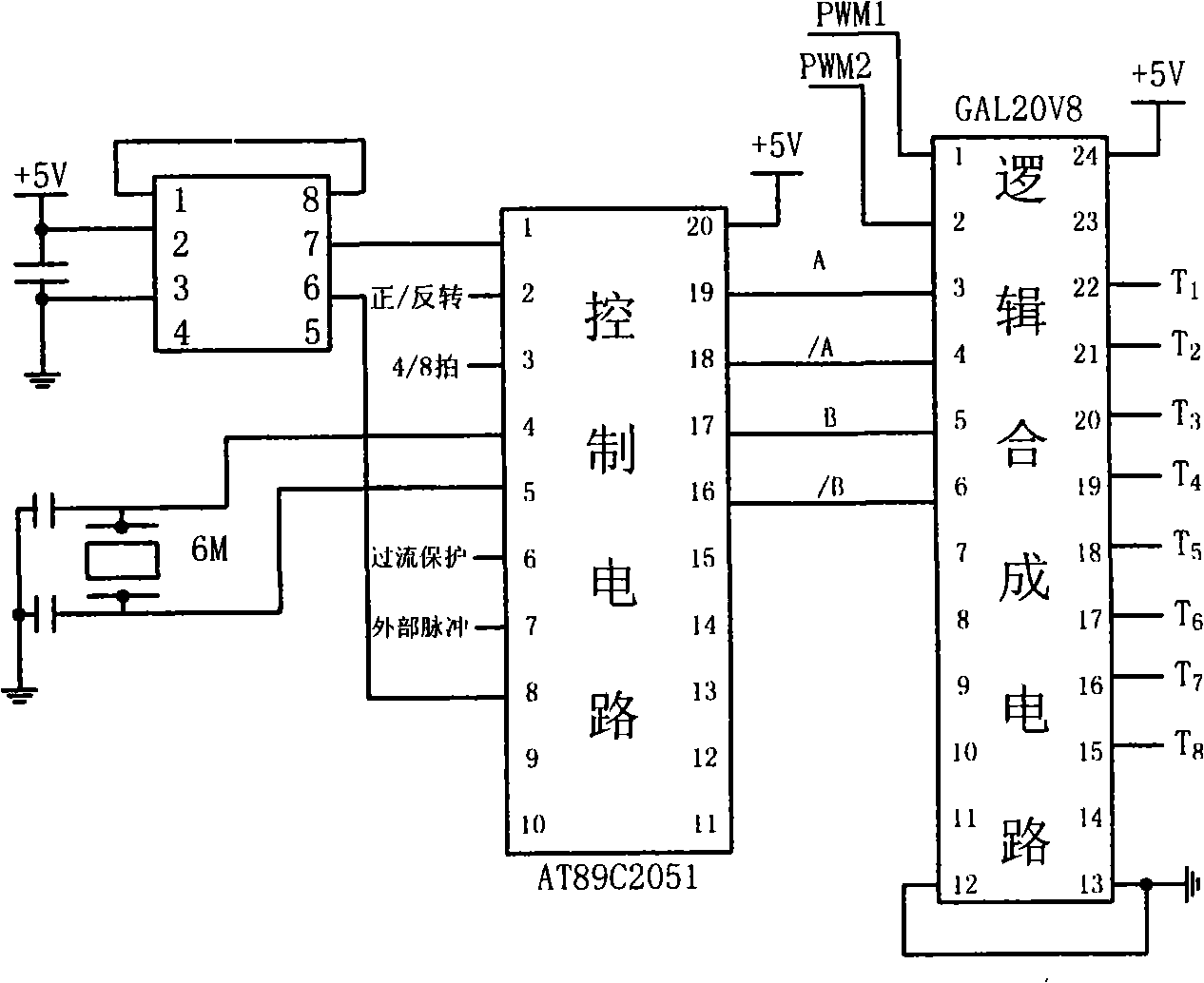

[0024] The present invention will be further described now in conjunction with accompanying drawing:

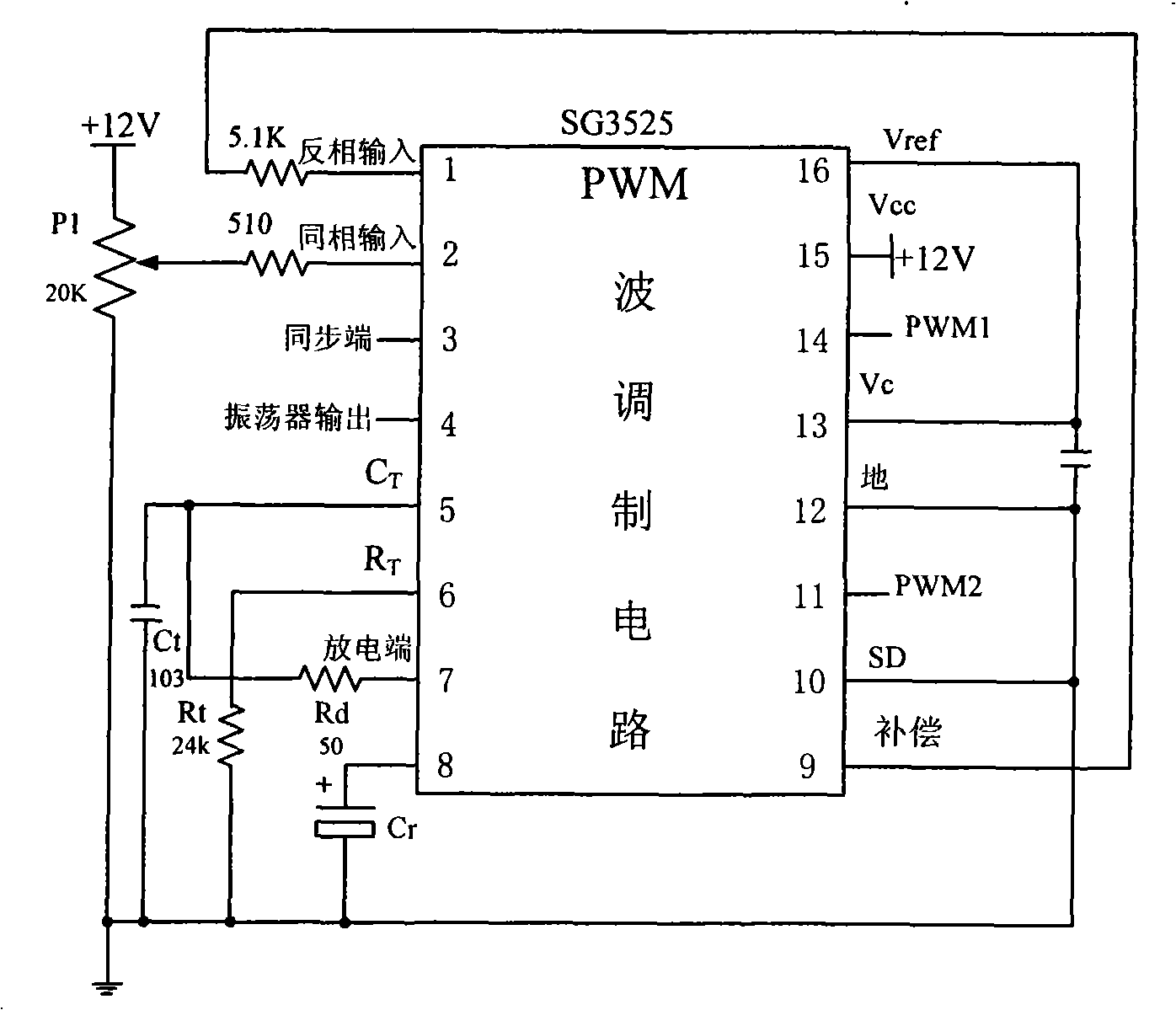

[0025] In this embodiment, the control circuit is mainly composed of a single-chip microcomputer AT89C2051. At the same time, in order to prevent the program from running away and effectively monitor the circuit, a watchdog circuit is used in the control circuit. The control circuit accepts external forward / reverse, pulse signals, 4 / 8 beat switching and overcurrent protection signals, which are input to the P3.0, P3.3, P3.1, and P3.2 ports of the microcontroller after photoelectric isolation. Output A, / A, B, / B 4-way signal. Among them, A and / A represent the positive and negative power bridge control signals of the A-phase winding, and B and / B represent the positive and negative power bridge control signals of the B-phase winding. The PWM wave modulation circuit adopts the integrated pulse width modulator SG3525 to realize the generation of the chopping current signal. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com