Processing technique of fried codonopsis lanceolata at vacuum and low temperature

A technology of vacuum low-temperature frying, Codonopsis rotundus, applied in medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, plant raw materials, etc., can solve the loss of nutrients in products, oil oxidation, and high fat content problem, to achieve the effect of low fat moisture content, unique flavor and crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

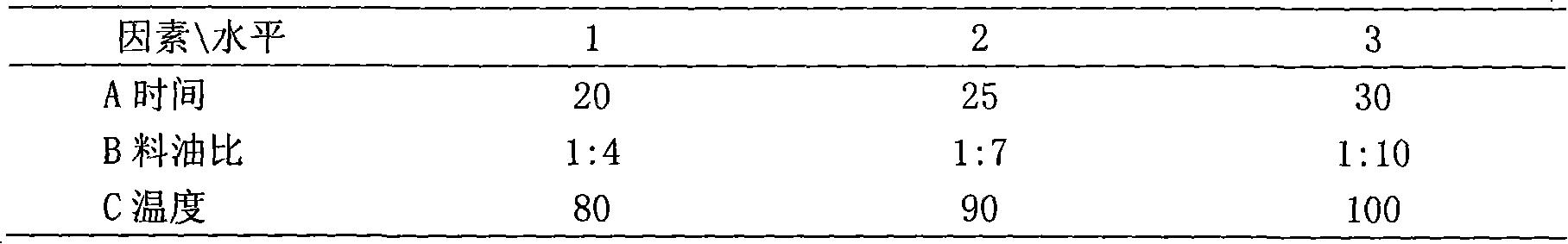

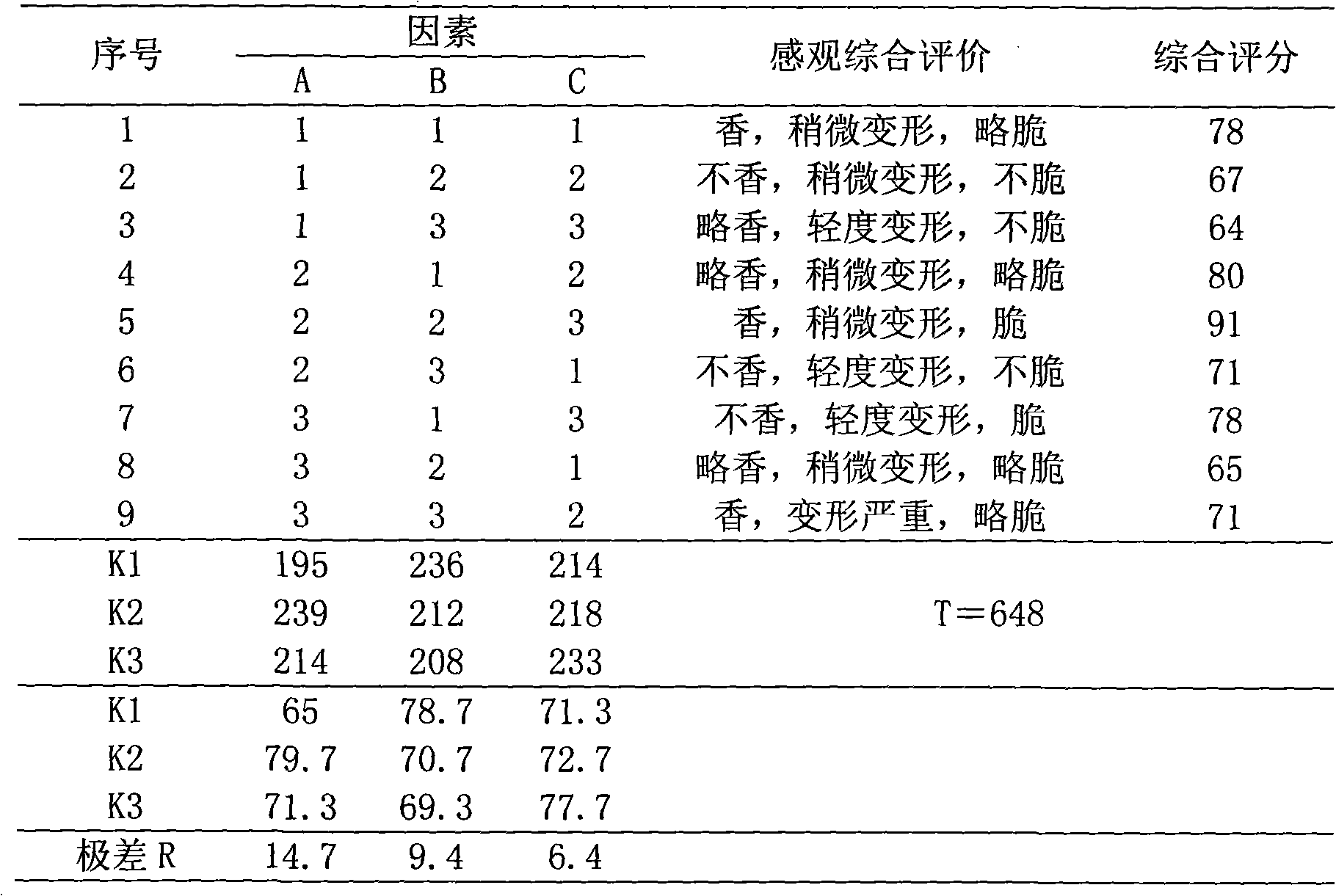

Method used

Image

Examples

Embodiment 1

[0019] Take the raw material fresh Codonopsis pilosula with clear water and remove mud, soak in lye and heat at a temperature not exceeding 90°C, heat for 3 minutes, take out clean water to wash away the lye, peel off the salted skin for later use; select the raw materials, and divide them into different groups according to their size and color Graded to facilitate subsequent processing and slicing; cut the graded Codonopsis verticillum slices into slices with a thickness of 1 mm; put the cut Codonopsis verticillum slices into clean water for desalination, the desalination time is 10 hours, and the mass ratio of water to raw materials is 4: 1. Change the water once every 2 hours; prepare a mixed filling solution with maltose and maltodextrin at a ratio of 2:1, and the concentration is 30%; take the cut Codonopsis pilosula slices and put them into the filling solution, and fill it in a vacuum Filling, vacuum degree 0.08MPa, filling time 45 minutes, take out and drain water after...

Embodiment 2

[0021] 1. Take the raw material fresh Codonopsis pilosula and remove the mud, soak it in lye and heat it at a temperature not exceeding 90°C, heat it for 5 minutes, take out the water to wash off the lye, peel off the salted skin for later use; select the raw material according to the size and color Divided into different grades to facilitate later processing and slicing; cut the graded Codonopsis pilosula into slices with a thickness of 2 mm; put the sliced Codonopsis pilosula into clear water for desalting, the desalination time is 10 hours, and the mass ratio of water to raw materials is 4:1, change the water every 2 hours or so; prepare a mixed filling solution with maltose and maltodextrin in a ratio of 2:1, the concentration of which is 30%; put the cut Codonopsis pilosula into the filling solution, fill For vacuum filling, the vacuum degree is 0.09MPa, and the filling time is 60 minutes. After 45 minutes, take out and drain the water; store the drained Codonopsis slice...

Embodiment 3

[0023] Take the raw material fresh Codonopsis pilosula and remove the mud, soak in lye and heat the temperature not to exceed 90°C, heat for 4 minutes, take out the clean water to rinse off the lye, peel off the salted skin for later use; select the raw materials, and divide them into different groups according to their size and color. Graded to facilitate subsequent processing and slicing; cut the graded Codonopsis verticillum into slices with a thickness of 1.5 mm; put the cut Codonopsis verticillum slices into clear water for desalination, the desalination time is 10 hours, and the mass ratio of water to raw materials is 4: 1. Change the water once every 2 hours; prepare a mixed filling solution with maltose and maltodextrin at a ratio of 2:1, and the concentration is 30%; take the cut Codonopsis pilosula slices and put them into the filling solution, and fill it in a vacuum Filling, vacuum degree 0.08MPa, filling time 50 minutes, take out and drain water after 45 minutes; p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com