Method for separating and preparing salidroside

A technology for salidroside and ethanol, which is applied in the field of preparation of salidroside separation, can solve the problems of inability to large-scale production, low product purity, organic residues and the like, and is suitable for industrialized large-scale production and has high sample purity. , the effect of low organic residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

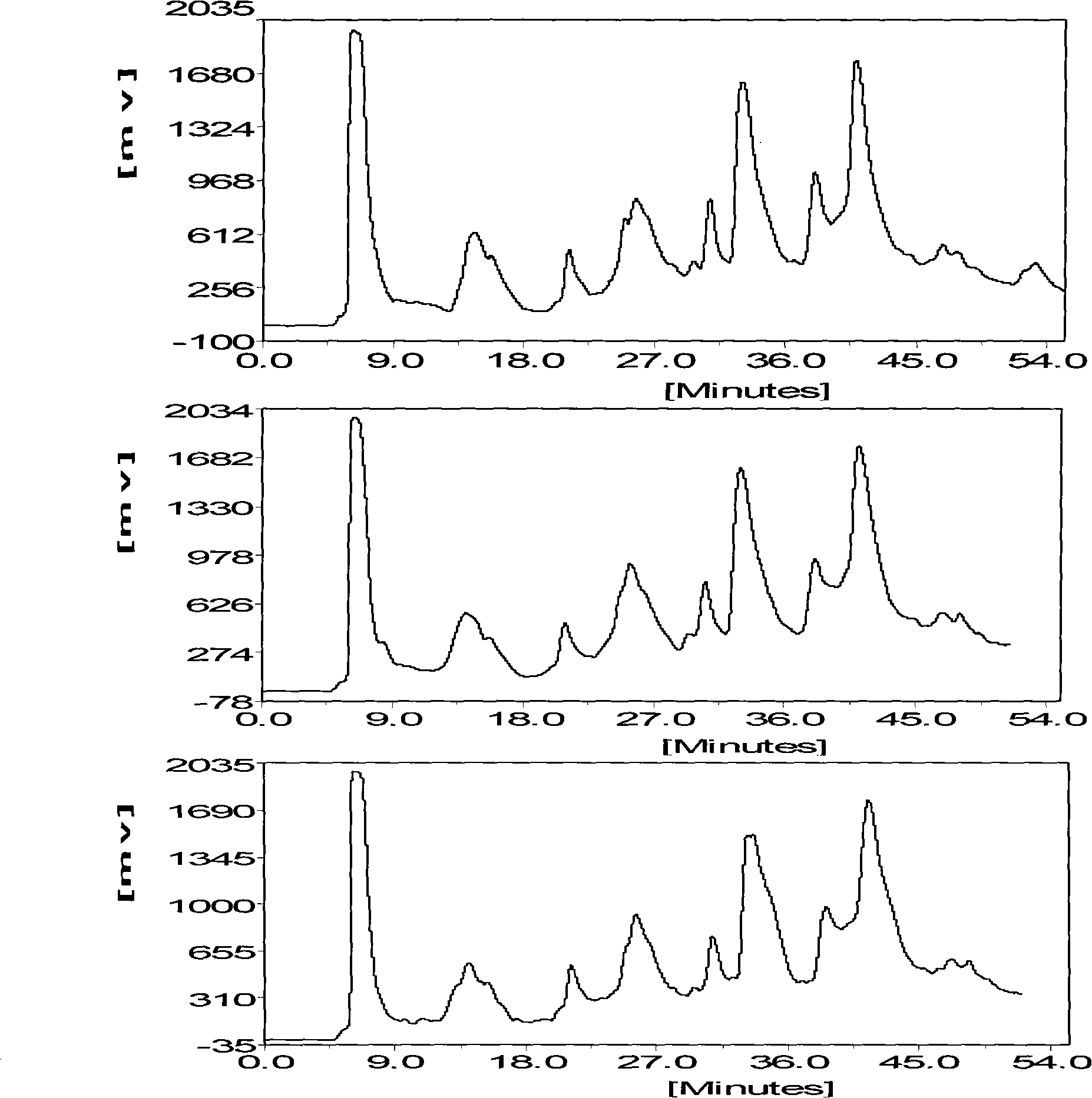

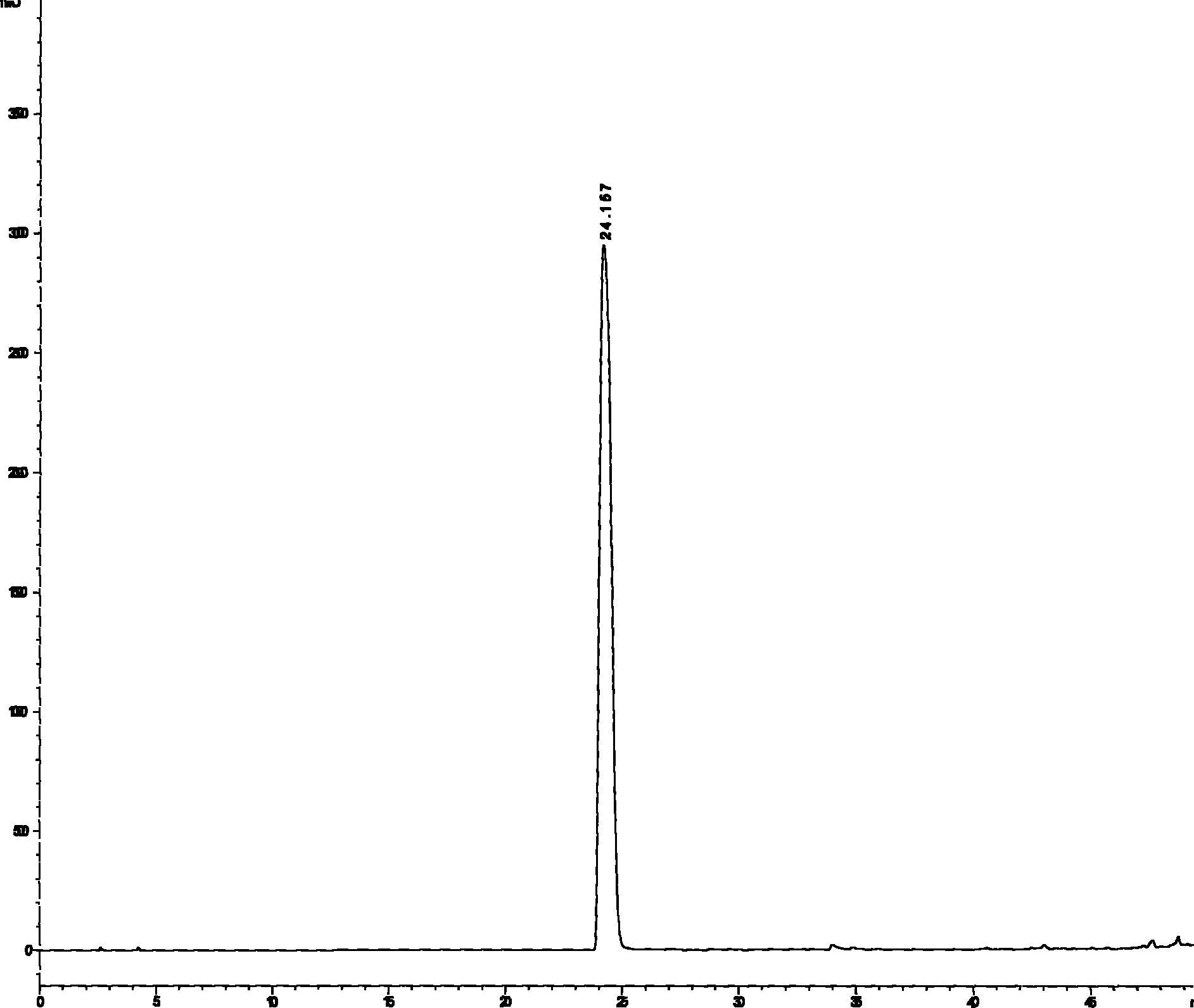

Embodiment 1

[0022] Crush the original medicinal material of Rhodiola rosea, weigh 1 kg quantitatively, put it in a 50-liter extraction tank, add 10 liters of water to decoct for 2 hours, filter, and save the filtrate for later use, add 10 liters of water to the filter residue and decoct for 2 hours, filter, and the filtrate Combined with the first time, the filter residue was discarded. The extract was concentrated by rotary evaporation to obtain 240 ml of extract with a relative density of 1.12. Add 412 milliliters of 95% ethanol to the extract, stir well, leave it in a refrigerator at 0°C for 24 hours, filter, discard the filter residue, and concentrate the filtrate to 160 milliliters, relative density 1.05, add 854 milliliters of 95% ethanol to the concentrated solution, fully Stir, refrigerate and stand at 0°C for 24 hours, filter, discard the filter residue, concentrate the filtrate until it has no alcohol smell, and centrifuge the concentrated solution in a high-speed centrifuge (20...

Embodiment 2

[0031] Crush the original medicinal material of Rhodiola rosea, weigh 0.5 kg quantitatively, put it in a 20-liter extraction tank, add 6 liters of water to decoct for 1 hour, filter, and save the filtrate for later use, add 5 liters of water to the filter residue and decoct for 3 hours, filter, and the filtrate Combined with the first time, the filter residue was discarded. The extract was concentrated by rotary evaporation to obtain 140 ml of extract with a relative density of 1.10. Add 240 milliliters of 95% ethanol to the extract, fully stir, refrigerate and stand for 24 hours at 0°C, filter, discard the filter residue, and concentrate the filtrate to 40 milliliters, relative density 1.07, add 428 milliliters of 95% ethanol to the concentrated solution, fully Stir, refrigerate and stand at 0°C for 24 hours, filter, discard the filter residue, concentrate the filtrate until it has no alcohol smell, and centrifuge the concentrated solution in a high-speed centrifuge (20,000 r...

Embodiment 3

[0035] Crush the original medicinal material of Rhodiola rosea, weigh 5 kg quantitatively, put it in a 250-liter extraction tank, add 60 liters of water to decoct for 2 hours, filter, and save the filtrate for later use, add 60 liters of water to the filter residue and decoct for 2 hours, filter, and the filtrate Combined with the first time, the filter residue was discarded. The extract was concentrated by rotary evaporation to obtain 1.2 liters of extract with a relative density of 1.13. Add 2.1 liters of 95% ethanol to the extract, stir fully, and refrigerate at 0°C for 24 hours, filter, discard the filter residue, and concentrate the filtrate to 0.7 liters, relative density 1.08, add 3.8 liters of 95% ethanol to the concentrated solution, fully Stir, refrigerate and stand at 0°C for 24 hours, filter, discard the filter residue, concentrate the filtrate until it has no alcohol smell, and centrifuge the concentrated solution in a high-speed centrifuge (20,000 rpm) to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com