Metal rubber flexible web gear

A metal rubber and gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of aging and damage, short life, etc., to suppress high-frequency components of noise, reduce Vibration noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

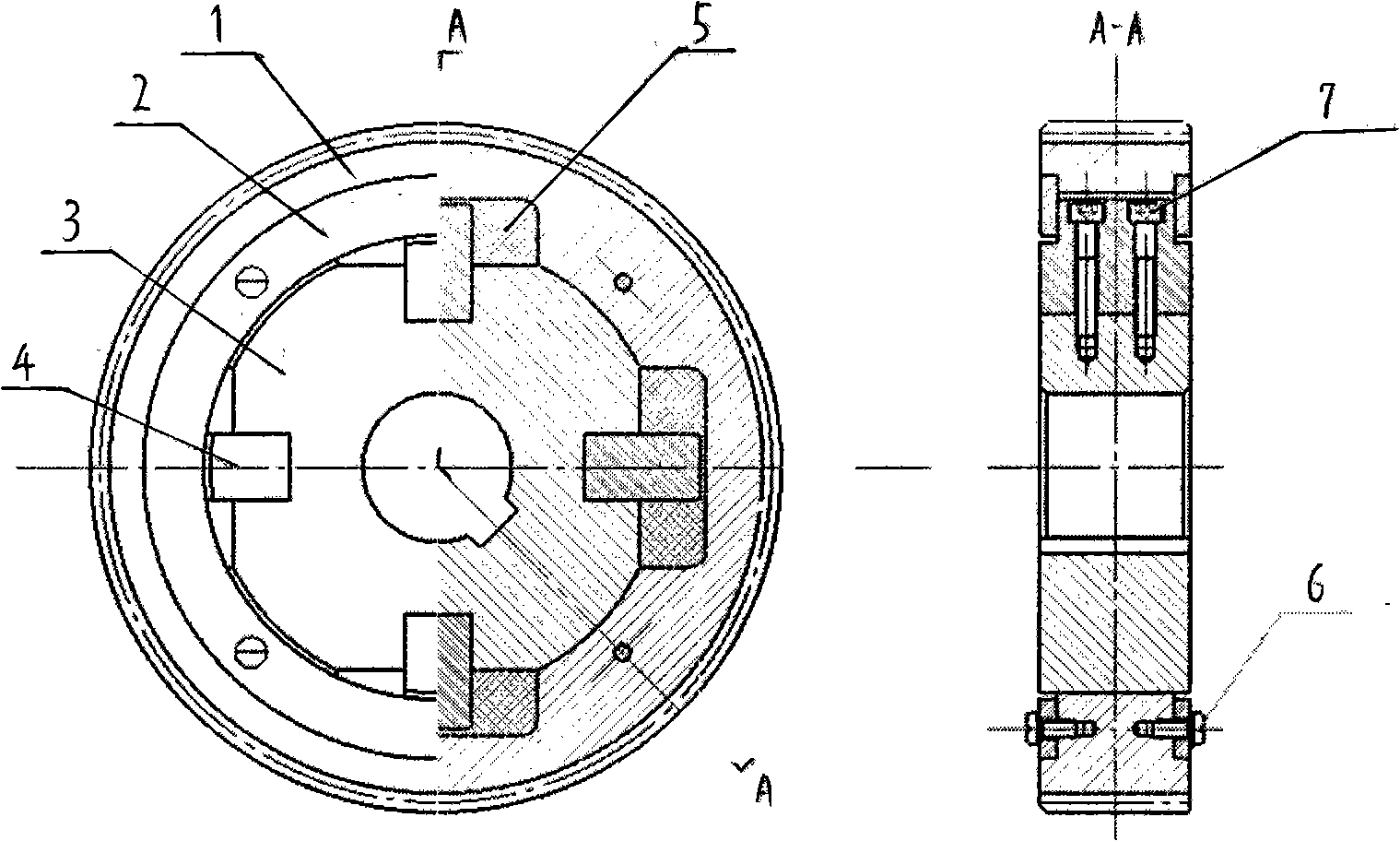

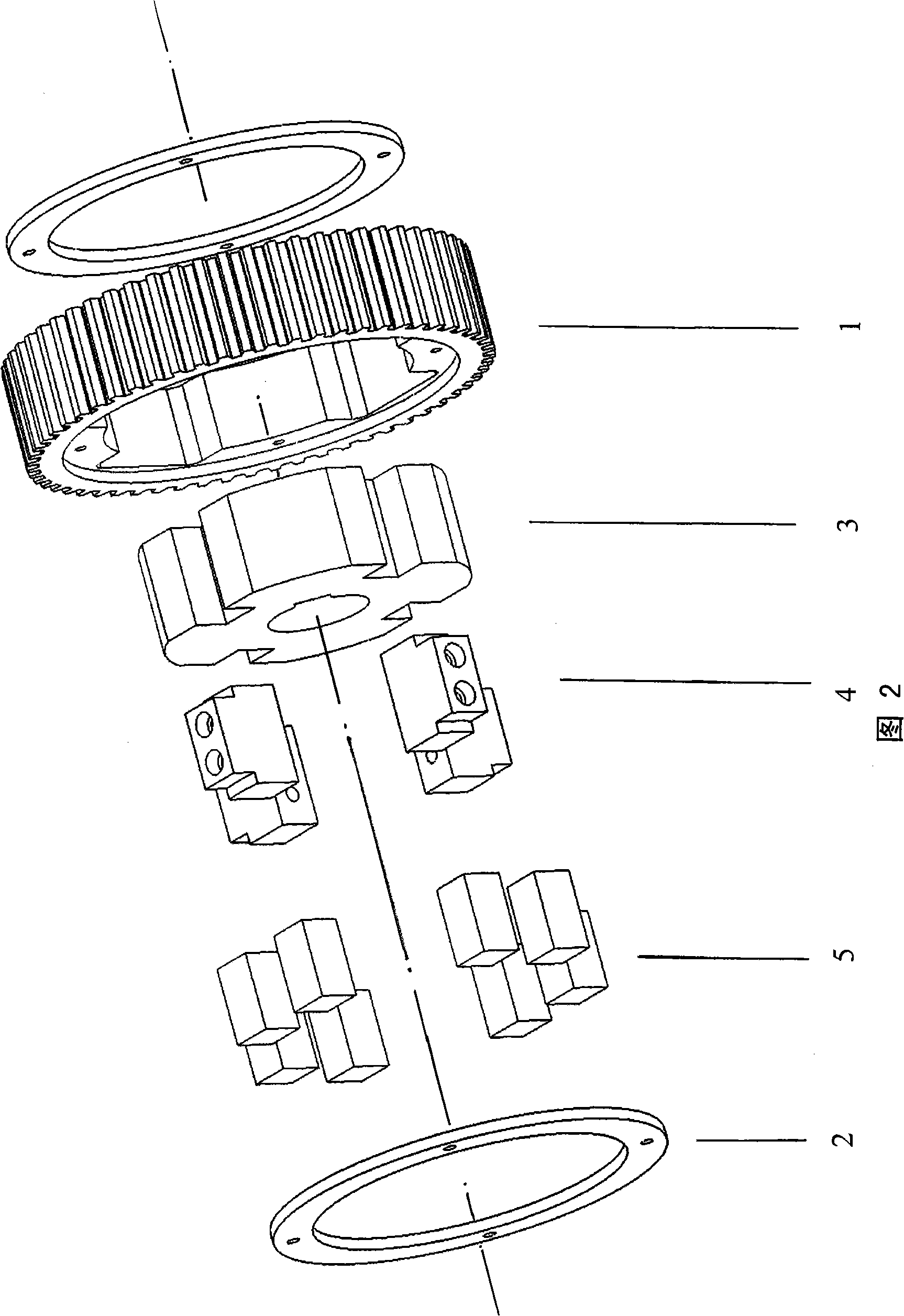

[0024] A kind of metal rubber flexible web gear of the present invention, as figure 1 , 2, which specifically includes: ring gear 1, retaining ring 2, wheel hub 3, key 4 and metal rubber block 5, etc., the ring gear 1 is evenly punched with a rectangular through hole along its inner diameter and circumference; The ring 1 is designed separately, and there is a keyway at the position corresponding to the through hole of the ring gear; the key 4 is matched with the keyway of the hub 3, and it is connected with the hub 3 through the hexagon socket head screw 7; the metal rubber Block 5 is embedded in the gap formed by hub, key and ring gear. During the normal operation of the gear, the metal rubber will be squeezed when the hub and the ring gear rotate relative to each other. Since the metal rubber has certain elasticity and good damping characteristics, the above design can realize the vibration reduction and vibration isolation of the metal rubber flexible web gear. characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com