Farm machinery capable of crushing corn straw and returning the same to farmland

A technology of corn stalks and agricultural machinery, applied in the field of agricultural machinery, can solve problems such as air pollution, affecting the depth of cultivated land, hindering the soil coverage of wheat seeds, etc., and achieve the effect of improving soil structure and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

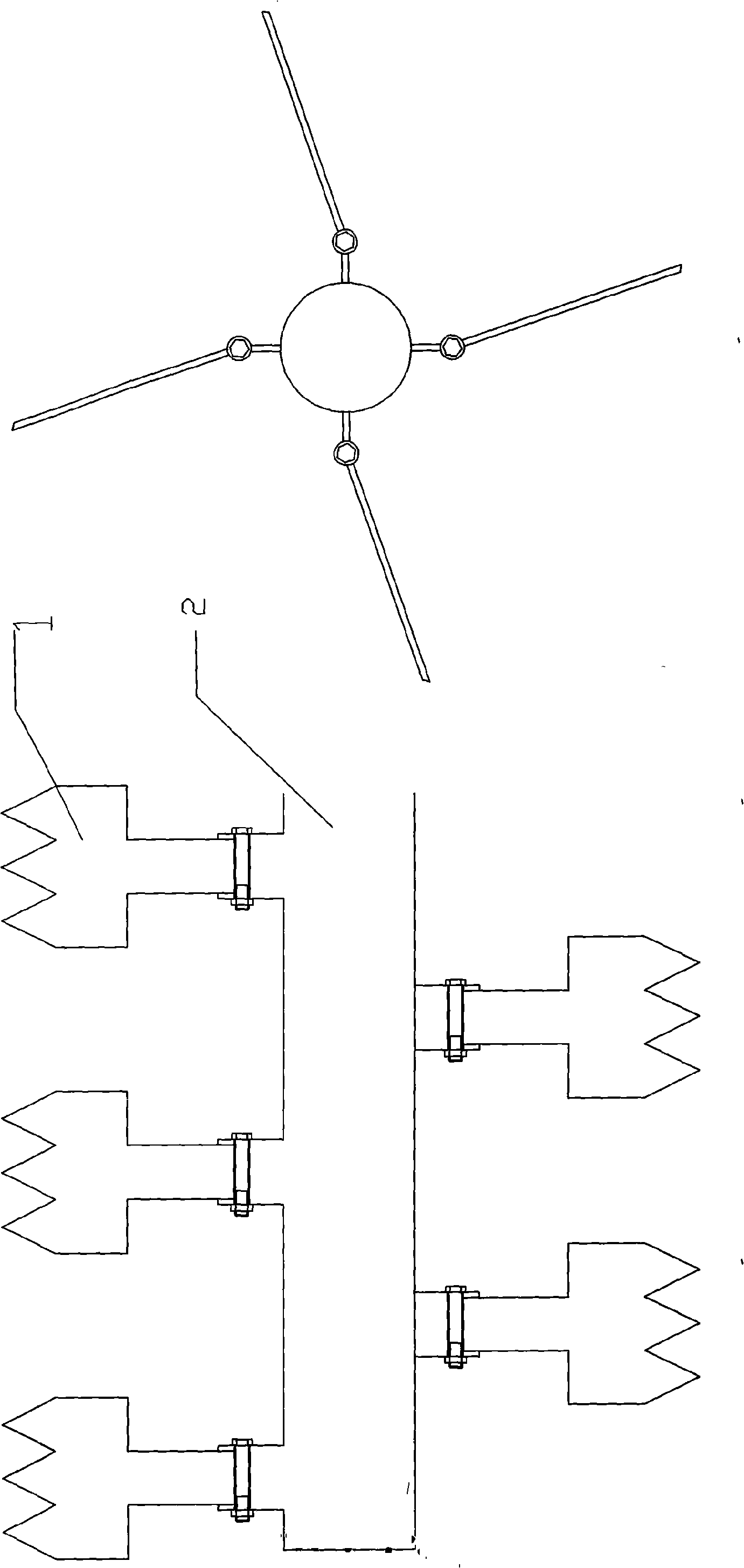

[0022] figure 1 The shape of the cutter (1) in the middle is to avoid affecting the subsequent sowing in order to be able to process the corn stalk thinner and shorter. It is connected together with a bolt and the shaft (2), and the purpose of the movable connection is to better protect the cutting tool. Because the gap between the cutter and the shaft is very easily filled up by the wound corn stalks and affects the mechanical work, so that the work effect is not satisfactory and abandoned.

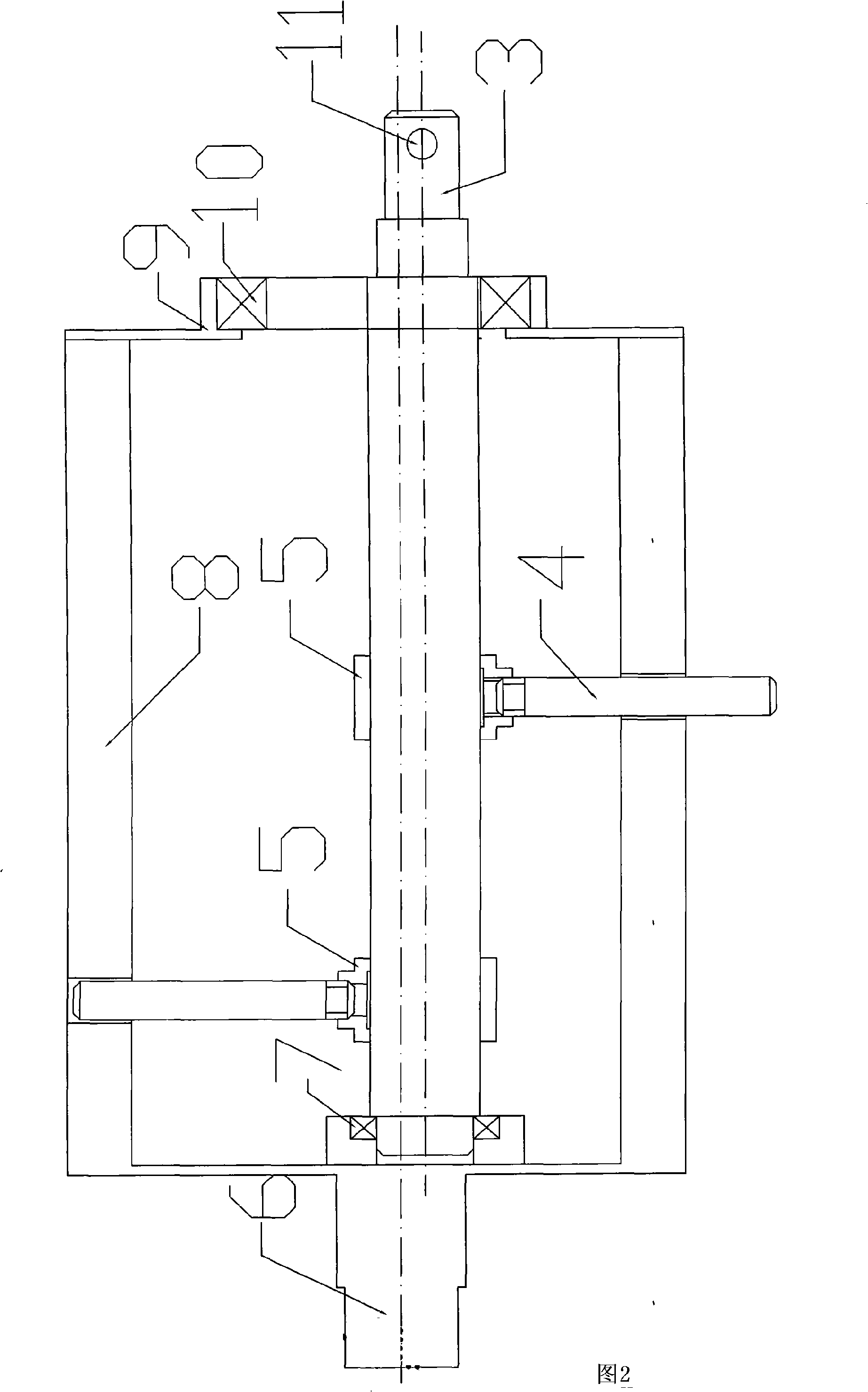

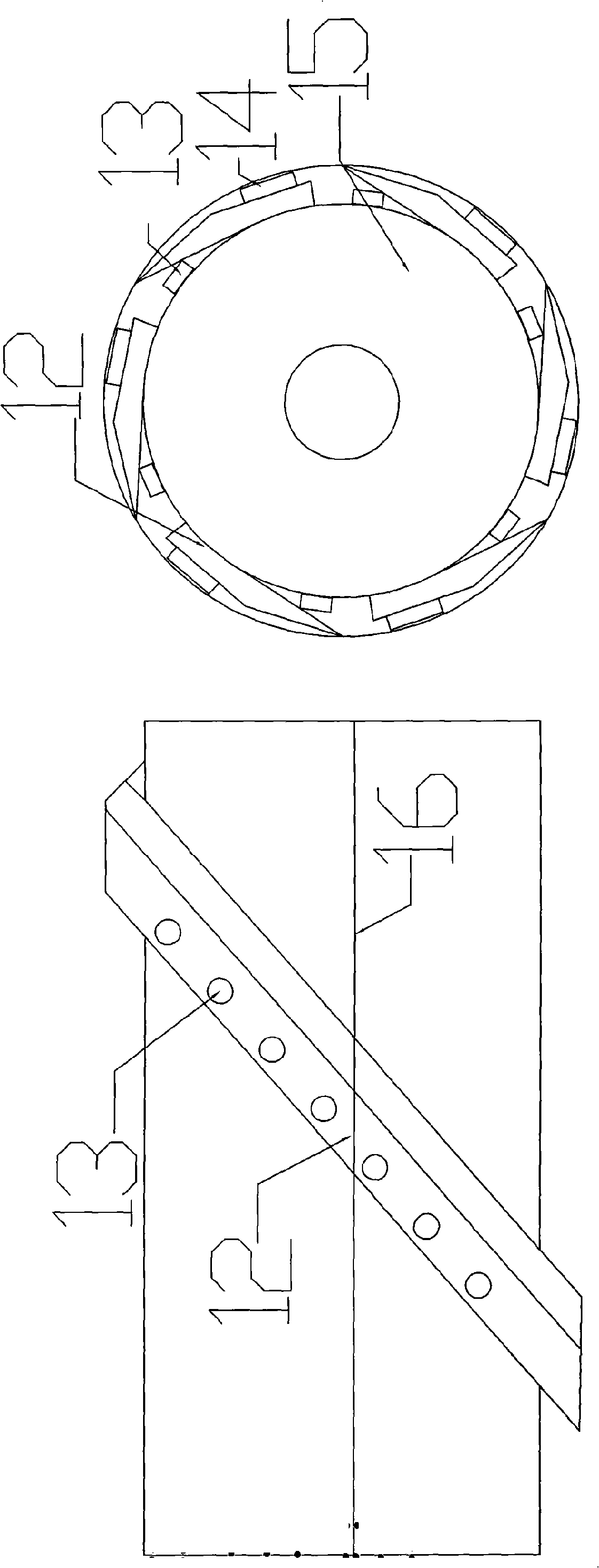

[0023] Mechanism among Fig. 2 is exactly the corn stalk picking-up mechanism designed in order to solve the winding problem of corn stalk. Axle (6) and cylinder (8) are one, and axle (3) is connected together with them by bearing (7) and a bearing seat, has just formed an eccentric mechanism like this. The shaft (3) is fixed by the positioning pin through the pin hole (11) and cannot rotate. When the power is transmitted to the shaft (6), it drives the round tube (8) to rotate, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com