Method for improving ventilation sterilization speed of foods

A speed and food technology, applied in the field of food freezing equipment, can solve the problems of uneven distribution of air distribution, large equipment volume, poor quality of frozen products, etc., and achieve the effect of preserving the original quality, reducing the volume and improving the freezing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

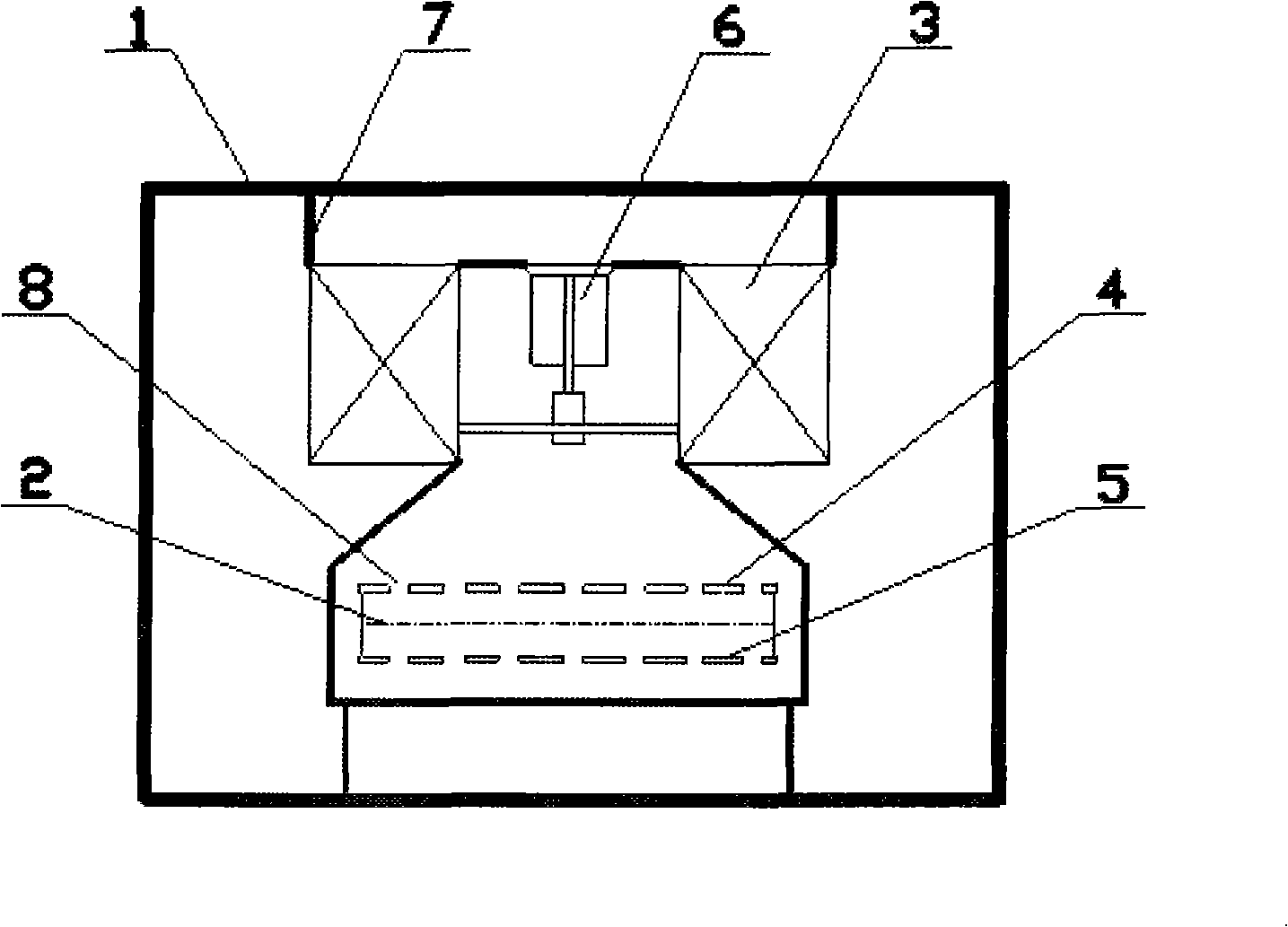

[0008] The present invention and its implementation will be further described below in conjunction with the accompanying drawings.

[0009] Two evaporators (3) are installed on the upper part of the freezing device at the level with the height of both sides of the fan (6), and are connected with the fan (6) through the wind deflector (7).

[0010] During the implementation process, the food enters the stainless steel mesh belt (2), and is transported into the freezing room through the mesh belt. The blower fan (6) runs at high speed, sucks the cold air flow cooled by the evaporator (3), and sends it to the stainless steel mesh belt (2). Part of the air flows through the upper air equalizing plate (4) with a certain opening density above the mesh belt, and after being accelerated, it is directly sprayed to the upper surface of the stainless steel mesh belt (2), and the other part flows along the air deflectors (7) on both sides of the static pressure box. The space formed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com