Steel rib polyurethane foaming chair

A steel-bonded polyurethane and polyurethane technology, applied in the field of chairs, can solve the problems of hard seat plate and backrest, low strength of plastic chairs, short service life, etc., and achieve the effects of excellent resilience, beautiful appearance and high product quality.

Inactive Publication Date: 2008-10-29

STARWAY INTERNATIONAL HOME LIVING CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing plastic chairs still have the following disadvantages: one is that the seat board and the backrest of the chair are very hard, and the air permeability is poor, and people feel bad and uncomfortable when sitting; the other is that the strength of the plastic chair is low and the service life is short

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

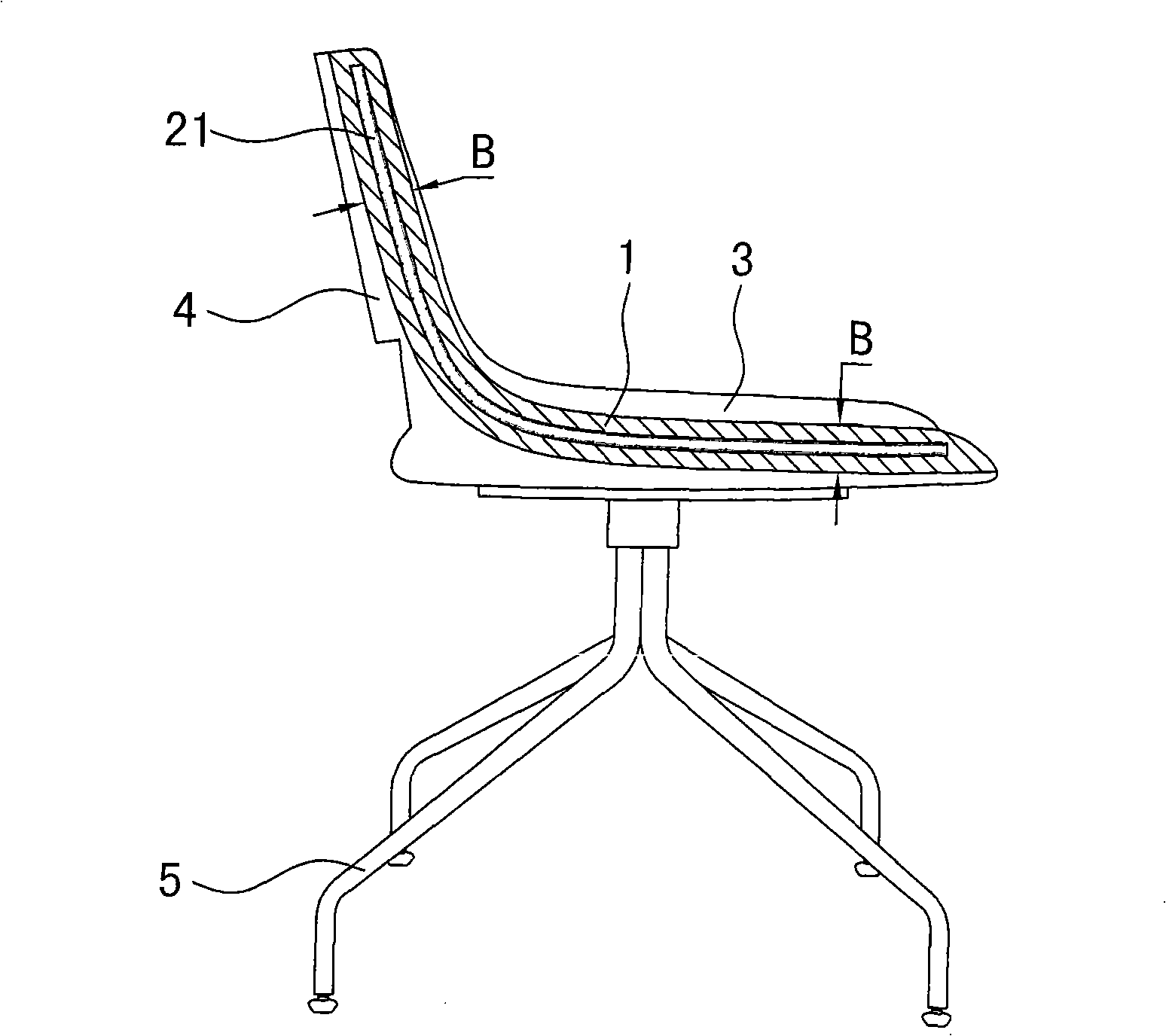

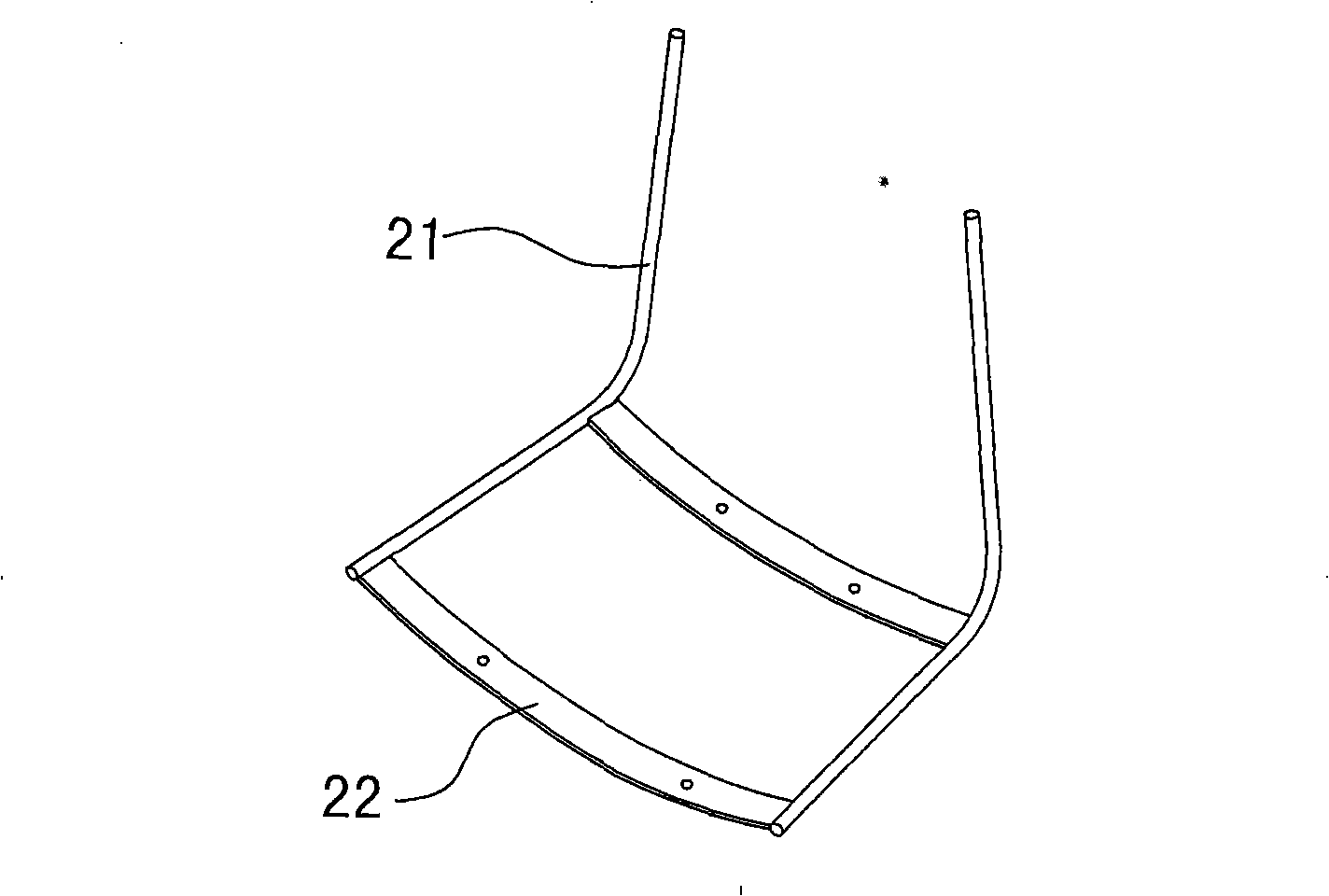

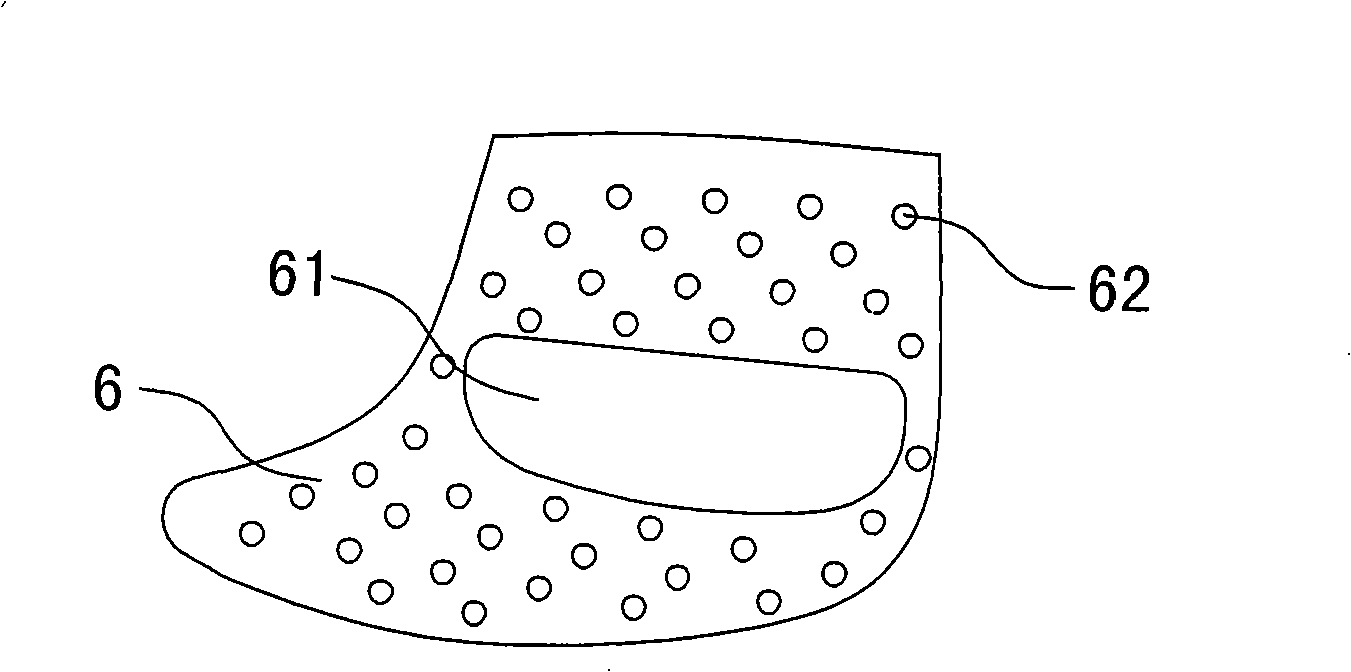

The invention discloses a steel-skeleton polyurethane foaming chair which comprises a chair seat board and a back board, with chair legs being connected under the seat board, and is characterized in that the seat board and the back board are polyurethane foaming layers in which steel skeletons are embedded; the steel skeletons are steel pipes at the both sides of the back board and the seat board and the steel pipes at the both sides are connected by transverse steel sheets; the steel pipes and the steel sheets are fixed through the welding or the connection with rivets. Since the steel skeletons are embedded in the seat board and the back board, good rigidity, high mechanical strength and large bearing capacity of the steel skeletons can ensure that the chair can firmly stand and bear large pressure; furthermore, the polyurethane foaming layers are soft, elastic, smooth and slightly rough and can provide a soft and comfortable feeling for human bodies and are breathable; additionally, the chair wall is thicker than a plastic plate and the chair has an artistic appearance and can be applicable to houses, offices and hotels with a broad range of application and high grade.

Description

Steel bone polyurethane foam chair Technical field The invention relates to a chair, in particular to a steel frame polyurethane foamed chair, and belongs to the field of furniture. Background technique Chairs are closely related to people's life and work. There are many types of chairs. According to different manufacturing materials, they can be divided into wooden chairs, bamboo chairs, rattan chairs, steel chairs, cloth chairs, and plastic chairs. Plastic chairs are characterized by simple processing methods and low cost, and they have developed rapidly in recent years. However, the existing plastic chairs still have the following shortcomings: First, the seat plate and backrest of the chair are very hard, and the air permeability is poor, and people feel bad and uncomfortable when sitting up; second, the strength of the plastic chair is low and the service life is short. Therefore, most of the existing plastic chairs are suitable for temporary places such as outdoors, beache...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47C5/00

Inventor 叶根林

Owner STARWAY INTERNATIONAL HOME LIVING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com