Silicon capacitor microphone

A technology of microphones and silicon capacitors, applied in the field of microphones, can solve the problems of limited increase in the rear cavity, difficulty in manufacturing silicon microphone products, and increased product height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

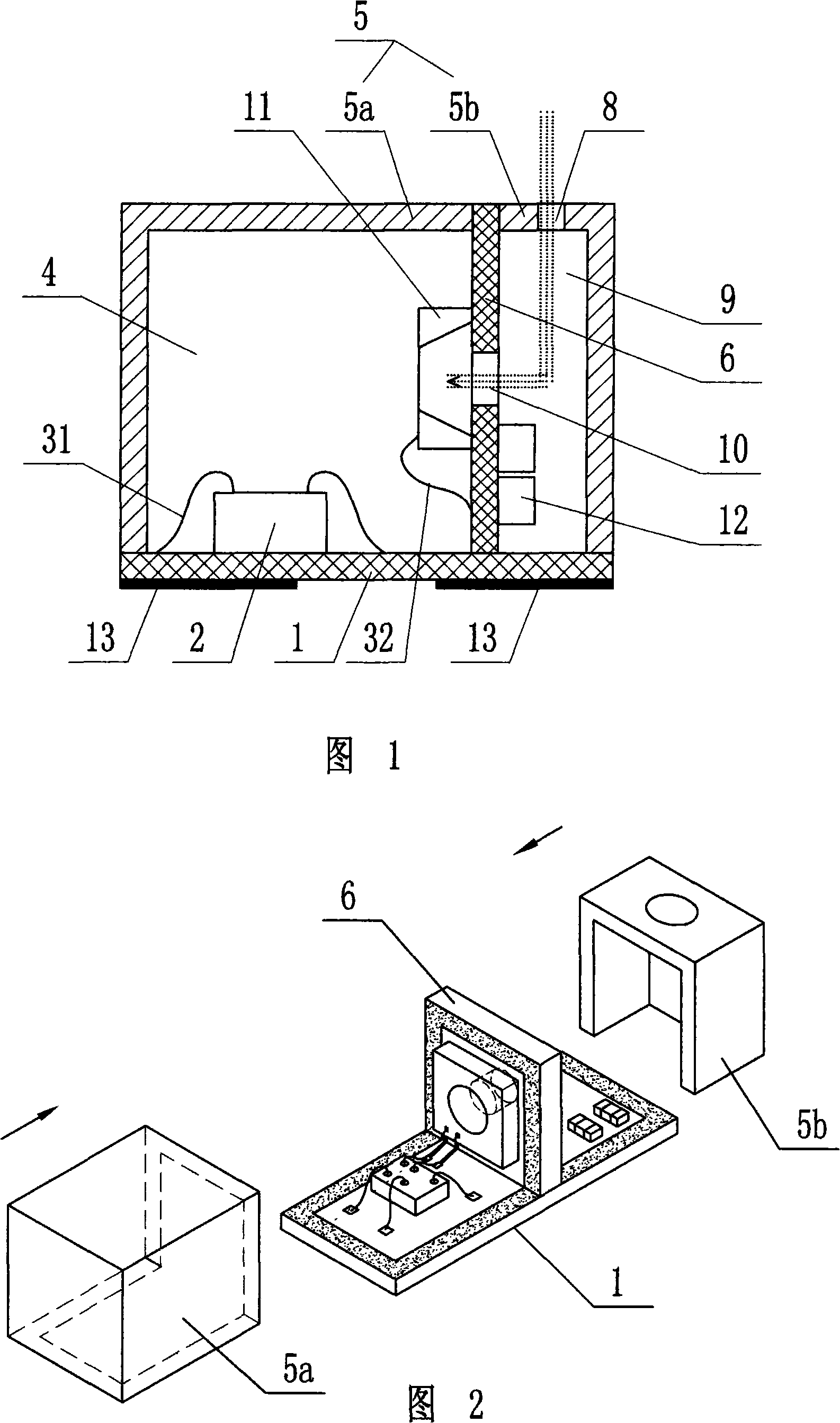

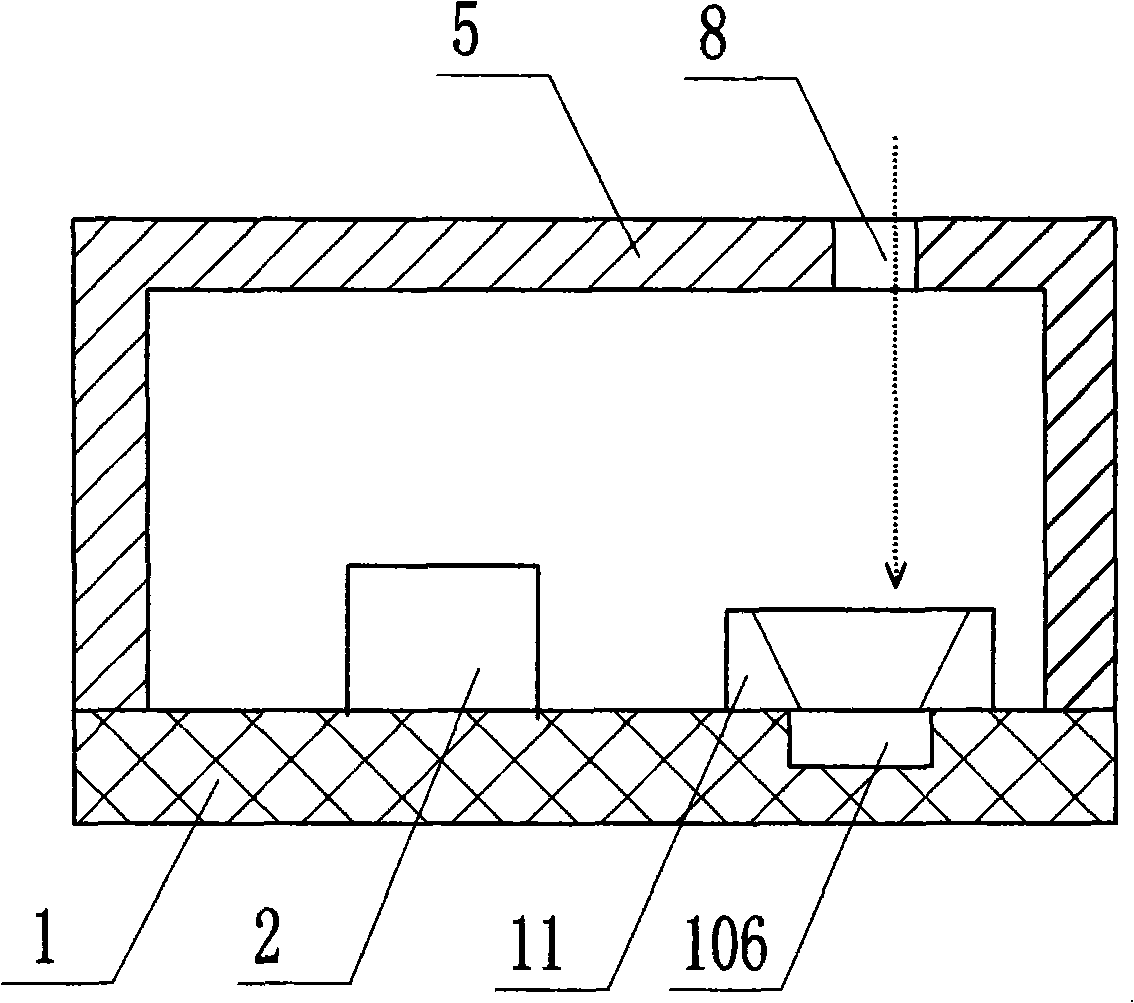

[0020] Embodiment 1: As shown in Figure 1 and Figure 2, the silicon capacitor microphone includes: a rectangular first circuit board 1, a plurality of pads 13 are arranged on the lower side of the first circuit board 1, and an integrated circuit 2 is installed on the upper side, integrated On the circuit 2, a gold wire 31 is connected to the first circuit board 1; on one side of the integrated circuit 2, a rectangular second circuit board 6 is installed on the first circuit board 1, and the second circuit board 6 and the first circuit board 1 The direction is vertical and mechanically connected together and part of the circuit is electrically connected. On the second circuit board 6, a MEMS acoustic chip 11 is installed on the side facing the integrated circuit 2, and a gold wire 32 is connected to the second circuit board 6 on the MEMS acoustic chip 11. There is an inner acoustic hole 10 on the bottom surface of the MEMS acoustic chip 11, and electronic components 12 such as c...

Embodiment 2

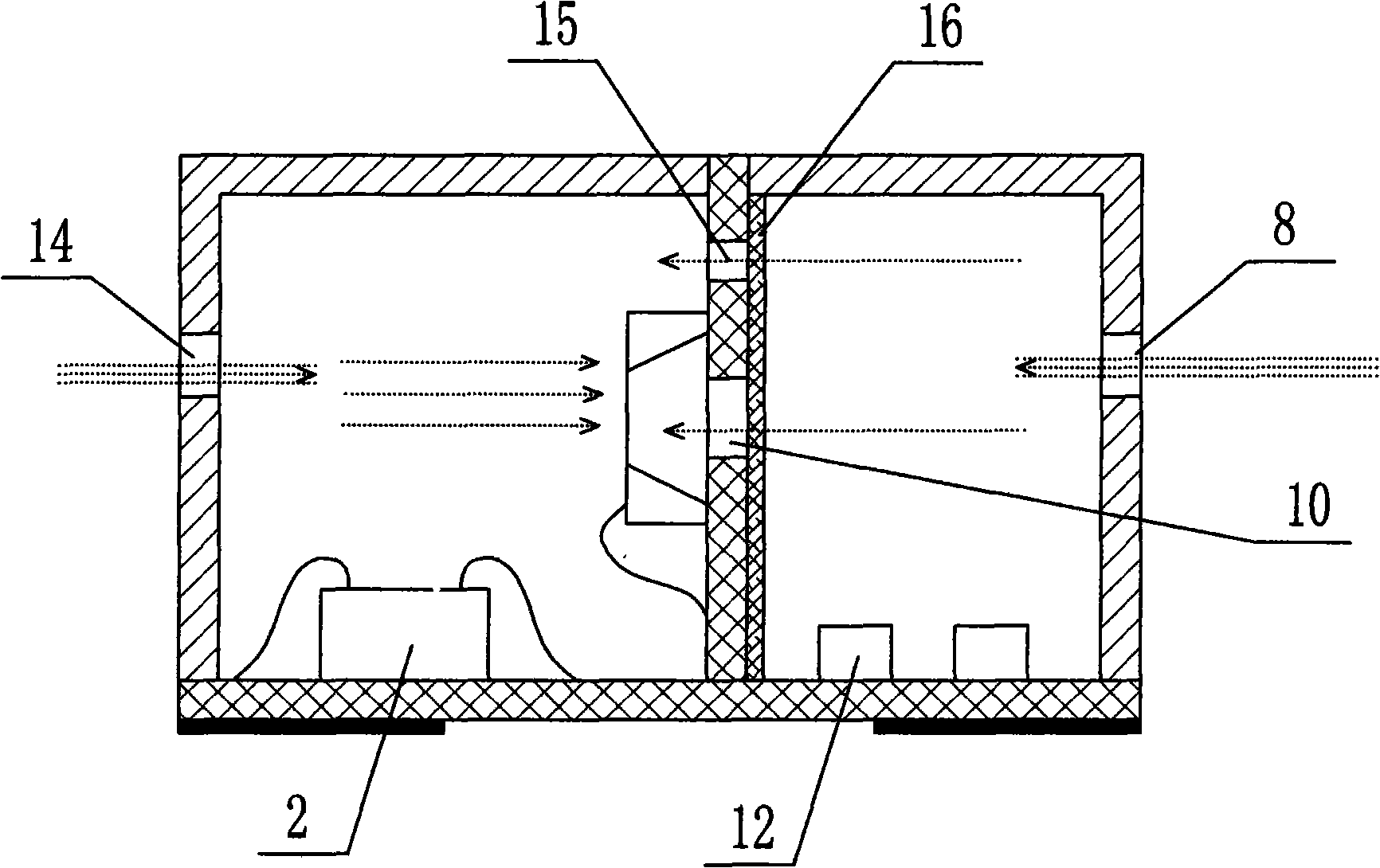

[0030] Embodiment two: if image 3As shown, the silicon condenser microphone of this embodiment is a unidirectional silicon condenser microphone. Compared with the embodiment 1, the adjustment of this case is: the first housing 5a and the second housing 5b are respectively provided with external sound holes 14 and 8; on the second circuit board 6, except the inner acoustic hole 10 below the MEMS acoustic chip 11, a cavity-connected acoustic hole 15 is also provided around the MEMS acoustic chip 11; on the second circuit board 6 relative to the MEMS acoustic One side of the chip 11 is affixed with an acoustic resistance 16, and the acoustic resistance 16 covers all sound holes set on the second circuit board 6; no capacitor 12 is installed on the second circuit board 6 relative to the side of the MEMS acoustic chip 11 and other parts, and these parts are installed on the first circuit board 1. There are no components such as capacitors on the side of the second circuit board 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com