Armature in rotary electric device and its manufacturing method

A technology of rotating electric machines and manufacturing methods, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as magnetic imbalance, achieve the effects of improving magnetic balance, reliable fixing, and reducing the mixing of windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, a first embodiment of the present invention will be described with reference to the drawings.

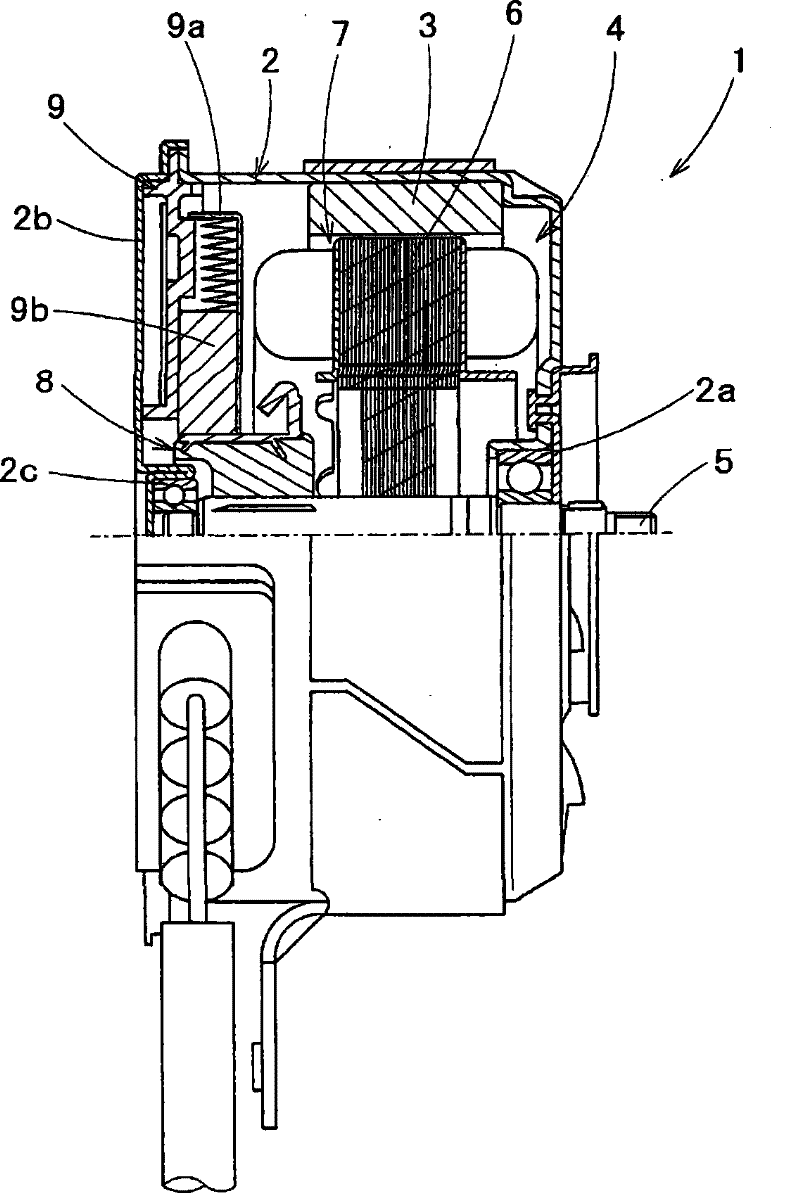

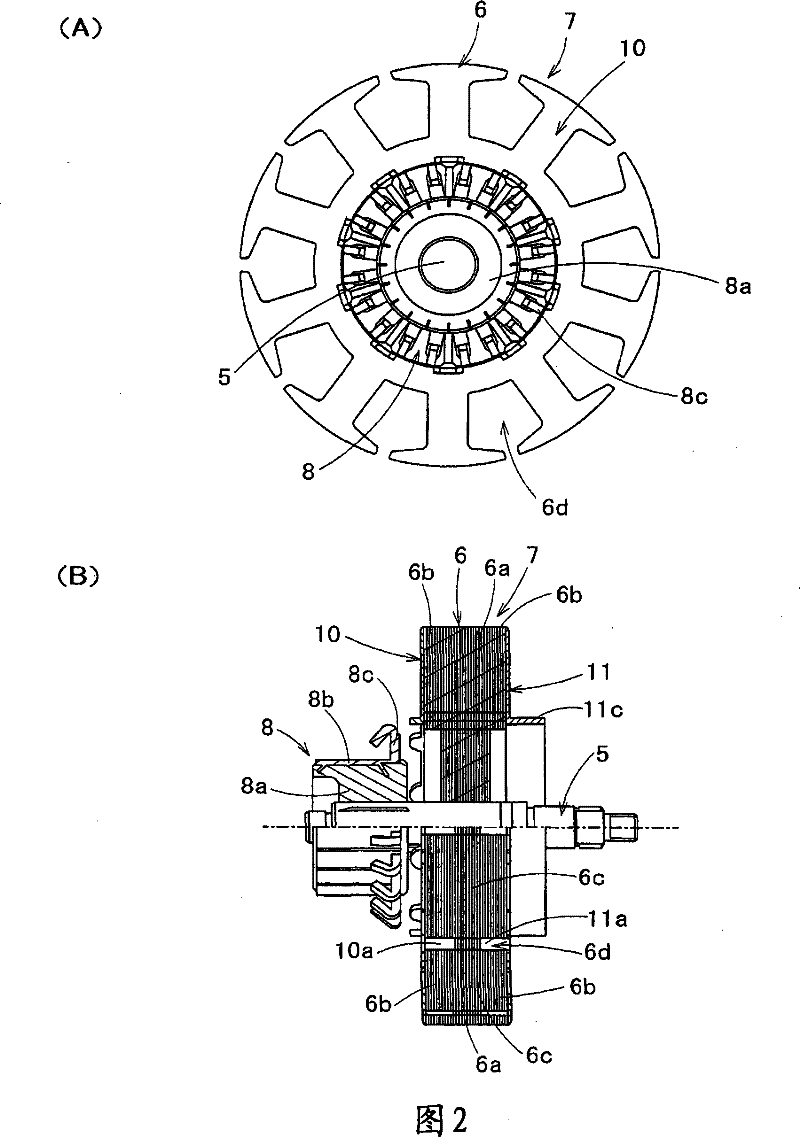

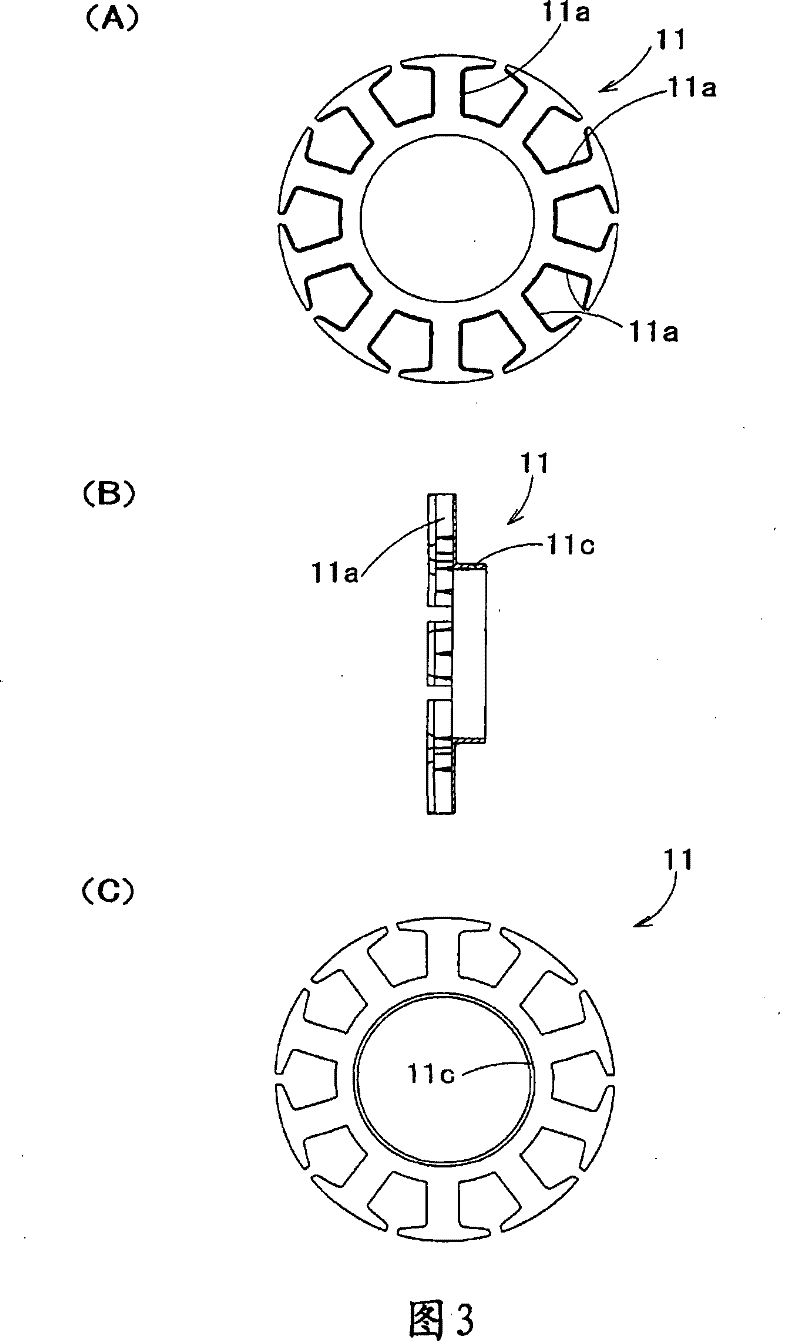

[0032] In the figure, 1 is an electric motor (rotating electric machine) as a driving source of an electrical component mounted on a vehicle, and on the inner peripheral surface of a bottomed cylindrical yoke (motor housing) 2 constituting the electric motor 1 , along A permanent magnet 3 for forming two pairs of N and S poles is fixed along the circumferential direction, thereby forming a four-pole motor 1 with the same magnetic poles facing along the radial direction. 4 is an armature, and a plurality of ring-shaped plates The armature core 7 formed by stacking the core material 6 is integrally embedded on the armature shaft 5 constituting the armature 4, and furthermore, the commutator 8 is externally embedded and fixed at the position of the front end of the armature core 7. . Further, the armature shaft 5 is pivotally supported at its proximal end by the yoke 2 vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com