Preparation of nano cobalt granule

A technology of nano-cobalt and particles, which is applied in the field of preparation of nano-cobalt particles, can solve the problems of inability to obtain particle size, good dispersion, single composition, etc., and achieve the effect of pollution-free by-products, simple preparation method, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

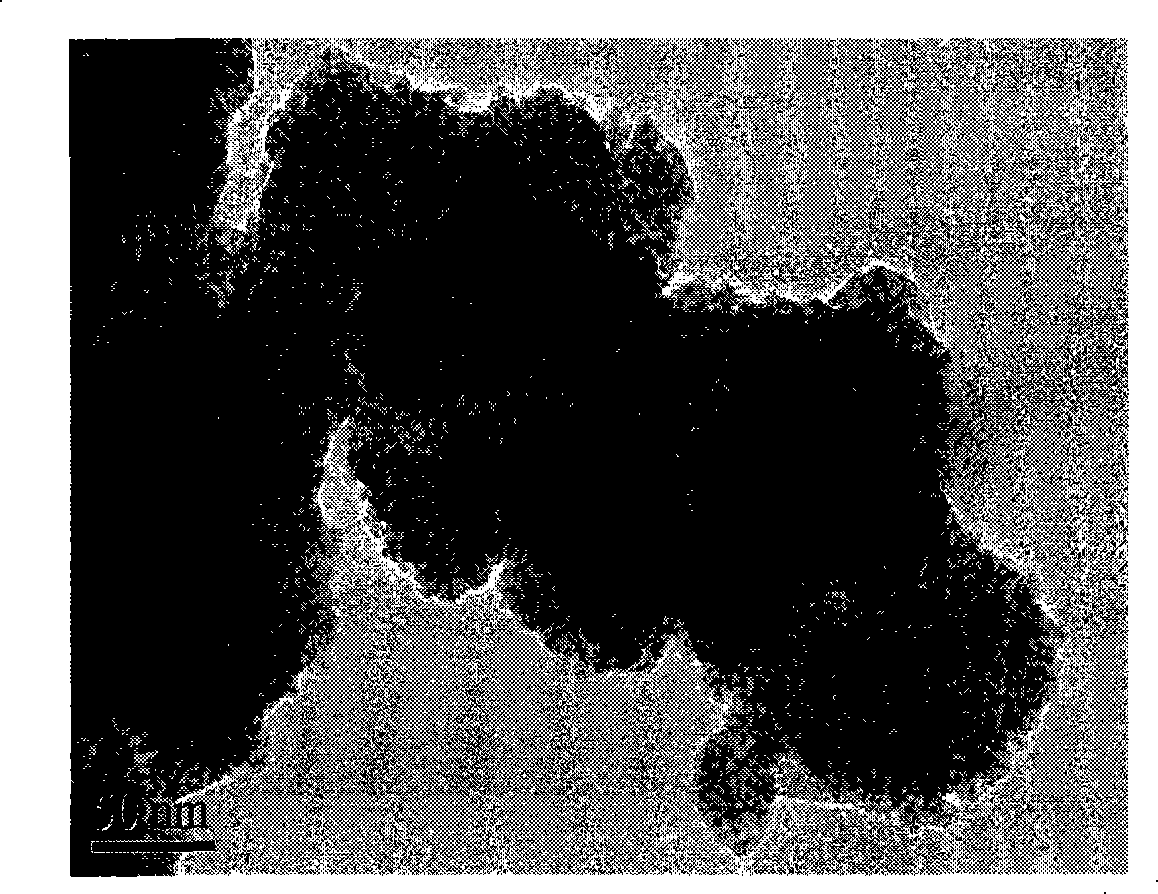

Embodiment 1

[0031] The specific steps of the method for preparing nano cobalt particles provided in this embodiment are as follows:

[0032] a) Preparation of template agent: Add the third-generation product (3G) of polyamide-amine dendrimer with benzene ring as the core to double distilled water, stir at 15~30℃ to completely dissolve it, and prepare 1mmol / L template agent solution;

[0033] b) Preparation of cobalt salt solution: add cobalt chloride to double distilled water, stir at 15-30°C to completely dissolve it, prepare 40mmol / L cobalt chloride solution;

[0034] c) At 15~30℃, add 10ml of the 40mmol / L cobalt chloride solution prepared above dropwise to 10ml of the 1mmol / L template solution prepared above, after dripping, continue to stir for 1~3 hours, where: cobalt The molar ratio of salt to template is 40:1;

[0035] d) Put NaBH at 15~30℃ 4 Add to double distilled water, make 10ml of 0.16mol / L sodium borohydride solution, and quickly add it to the mixed solution obtained in step c) aft...

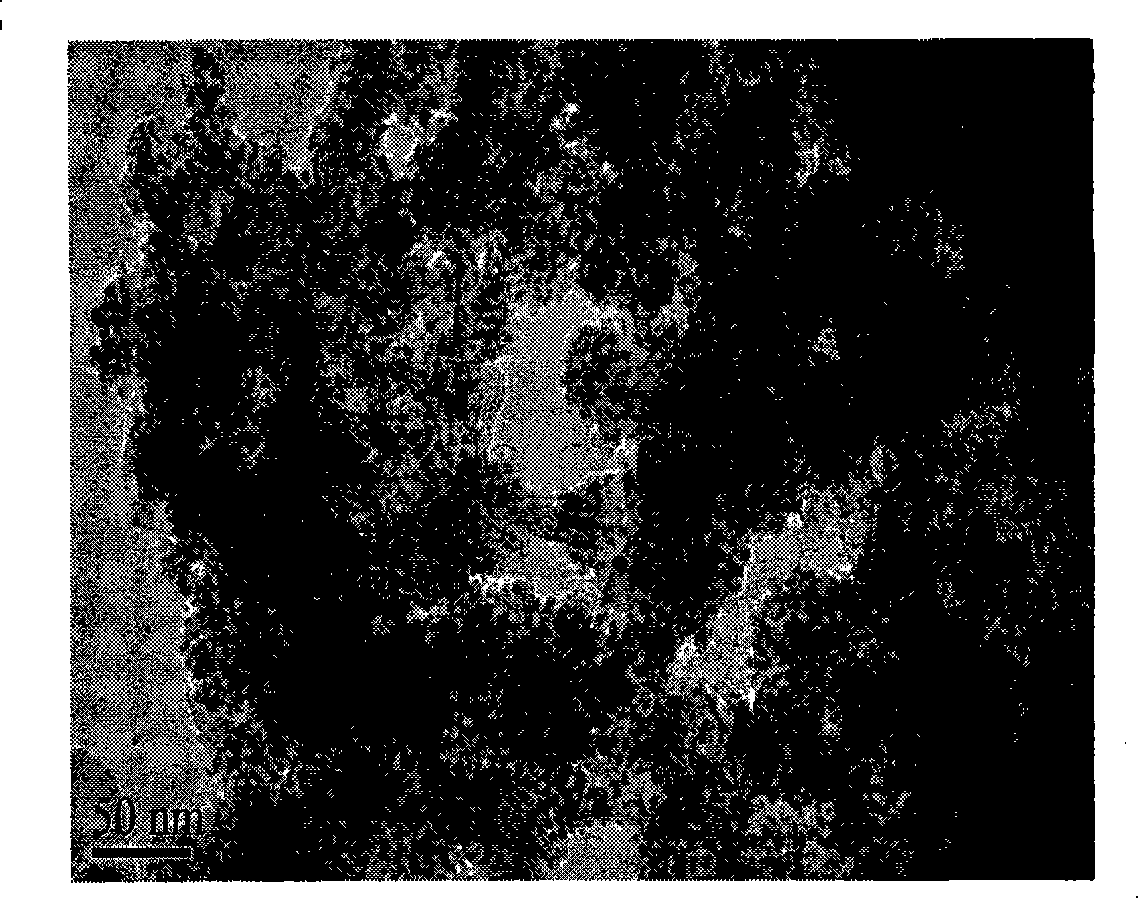

Embodiment 2

[0040] The specific steps of the method for preparing nano cobalt particles provided in this embodiment are as follows:

[0041] a) Preparation of template agent: Add the third-generation product (3G) of polyamide-amine dendrimer with benzene ring as the core to double distilled water, stir at 15~30℃ to completely dissolve it, and prepare 1mmol / L template agent solution;

[0042] b) Preparation of cobalt salt solution: add cobalt chloride to twice-distilled water, stir at 15~30℃ to completely dissolve it, prepare 30mmol / L cobalt chloride solution;

[0043] c) At 15~30℃, add 10ml of the 30mmol / L cobalt chloride solution prepared above dropwise to 10ml of the 1mmol / L template solution prepared above, and continue to stir for 1 to 3 hours after dripping. The molar ratio of salt to template is 30:1;

[0044] d) Put NaBH at 15~30℃ 4 Add to double distilled water, make 10ml of 0.12mol / L sodium borohydride solution, and quickly add it to the mixed solution obtained in step c) after prepara...

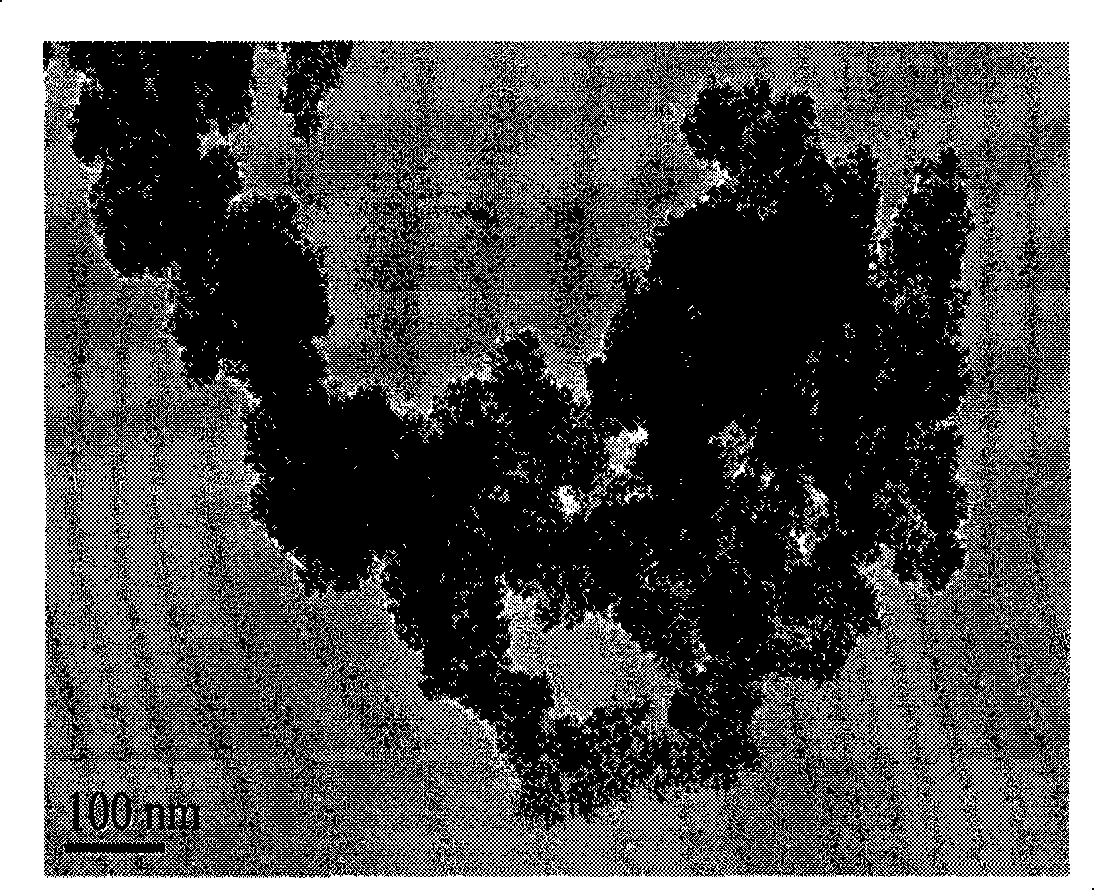

Embodiment 3

[0048] The specific steps of the method for preparing nano cobalt particles provided in this embodiment are as follows:

[0049] a) Preparation of template agent: Add the third-generation product (3G) of polyamide-amine dendrimer with benzene ring as the core to double distilled water, stir at 15~30℃ to completely dissolve it, and prepare 1mmol / L template agent solution;

[0050] b) Preparation of cobalt salt solution: add cobalt chloride to twice-distilled water, stir at 15-30°C to dissolve it completely, and prepare 20mmol / L cobalt chloride solution;

[0051] c) At 15~30℃, add 10ml of the 20mmol / L cobalt chloride solution prepared above dropwise to 10ml of the 1mmol / L template solution prepared above, and continue to stir for 1 to 3 hours after dropping. The molar ratio of salt to template is 20:1;

[0052] d) Put NaBH at 15~30℃ 4 Add to double distilled water, make 10ml of 0.08mol / L sodium borohydride solution, and quickly add it to the mixed solution obtained in step c) after pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com