Multifunctional automatic stacking conveyor

A multi-functional, conveyor technology, applied in the direction of conveyors, conveyor objects, object stacking, etc., can solve the problems of inability to load and unload goods, inconvenient use, and loading and unloading goods can only be done from right to left, etc., to achieve low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

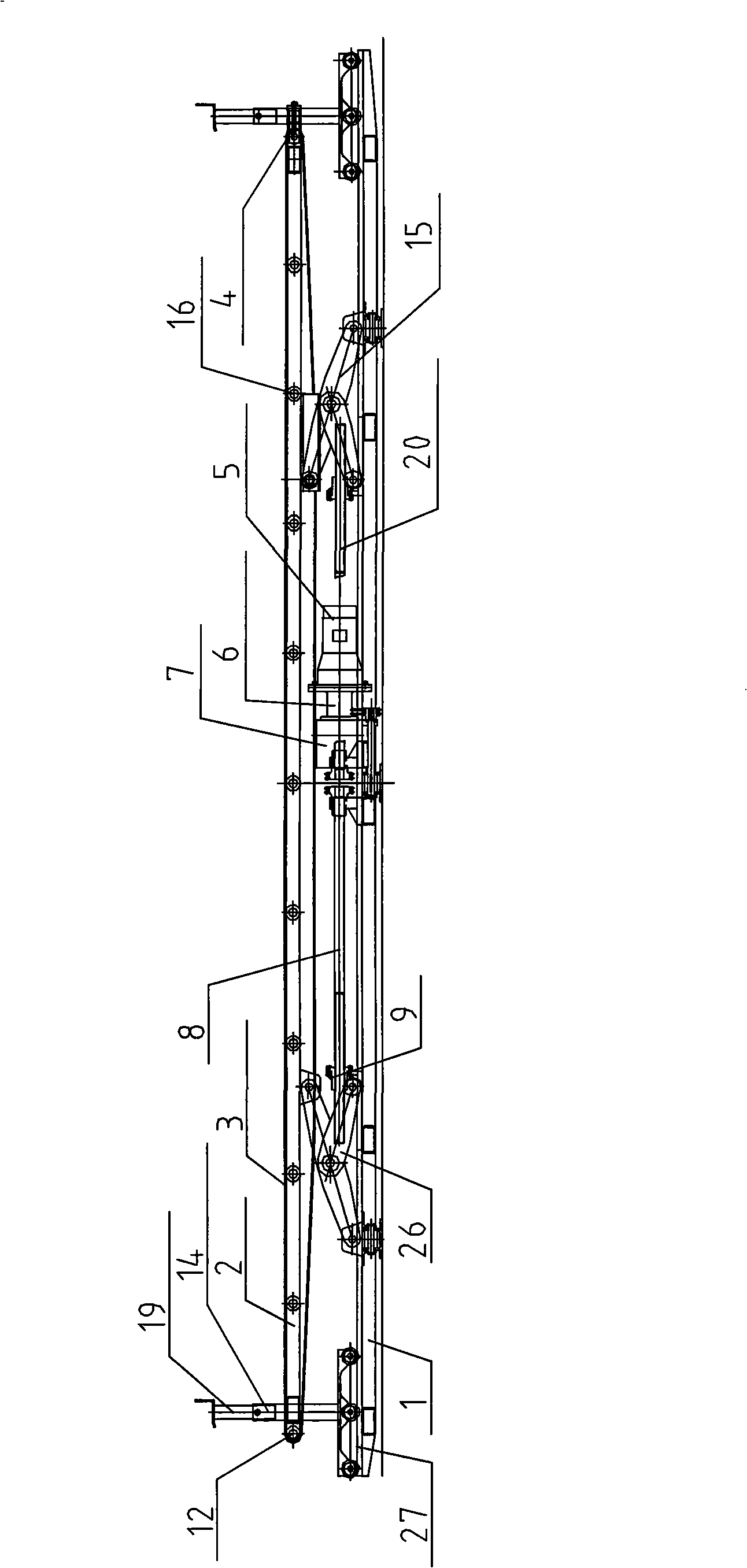

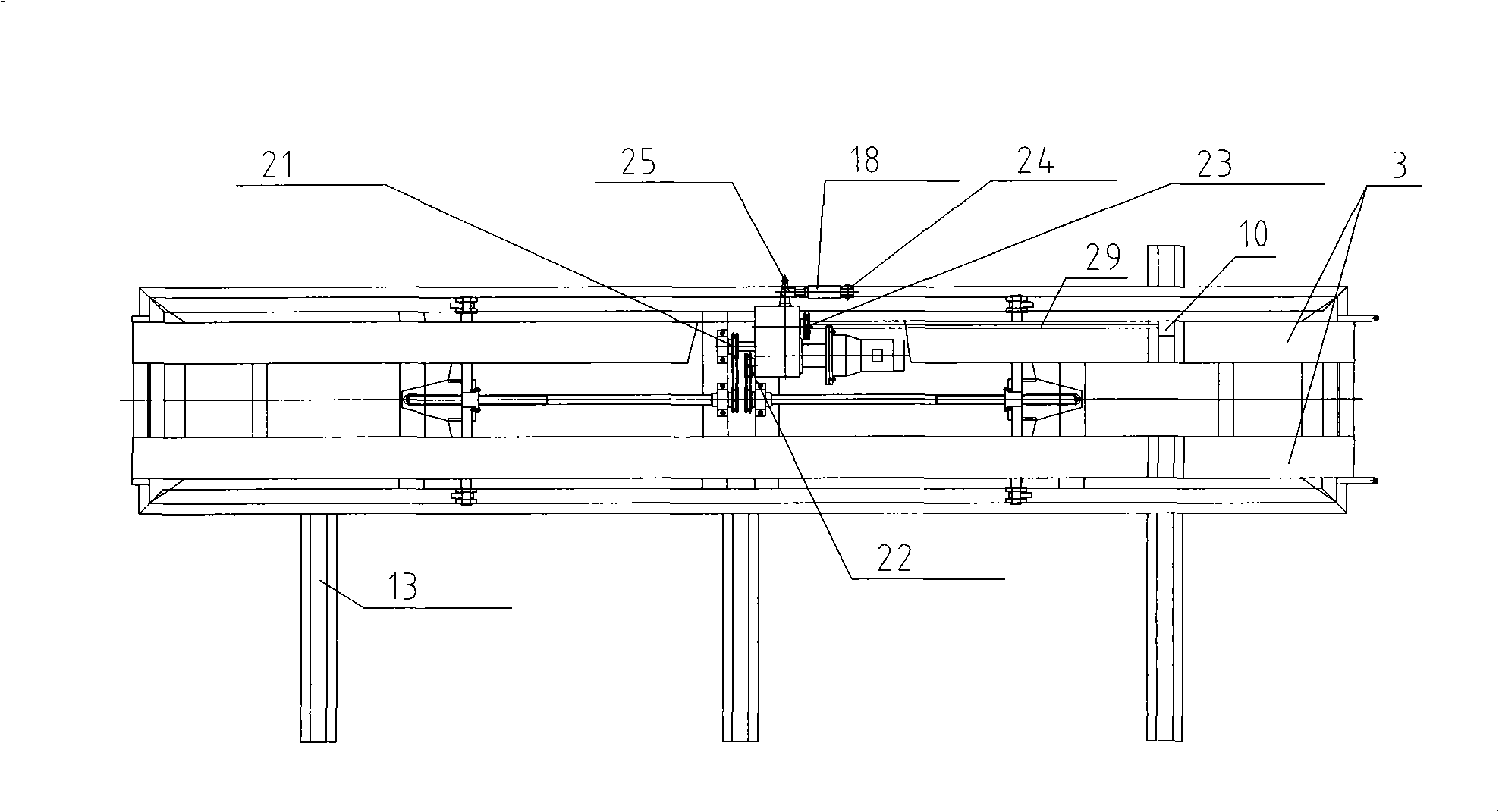

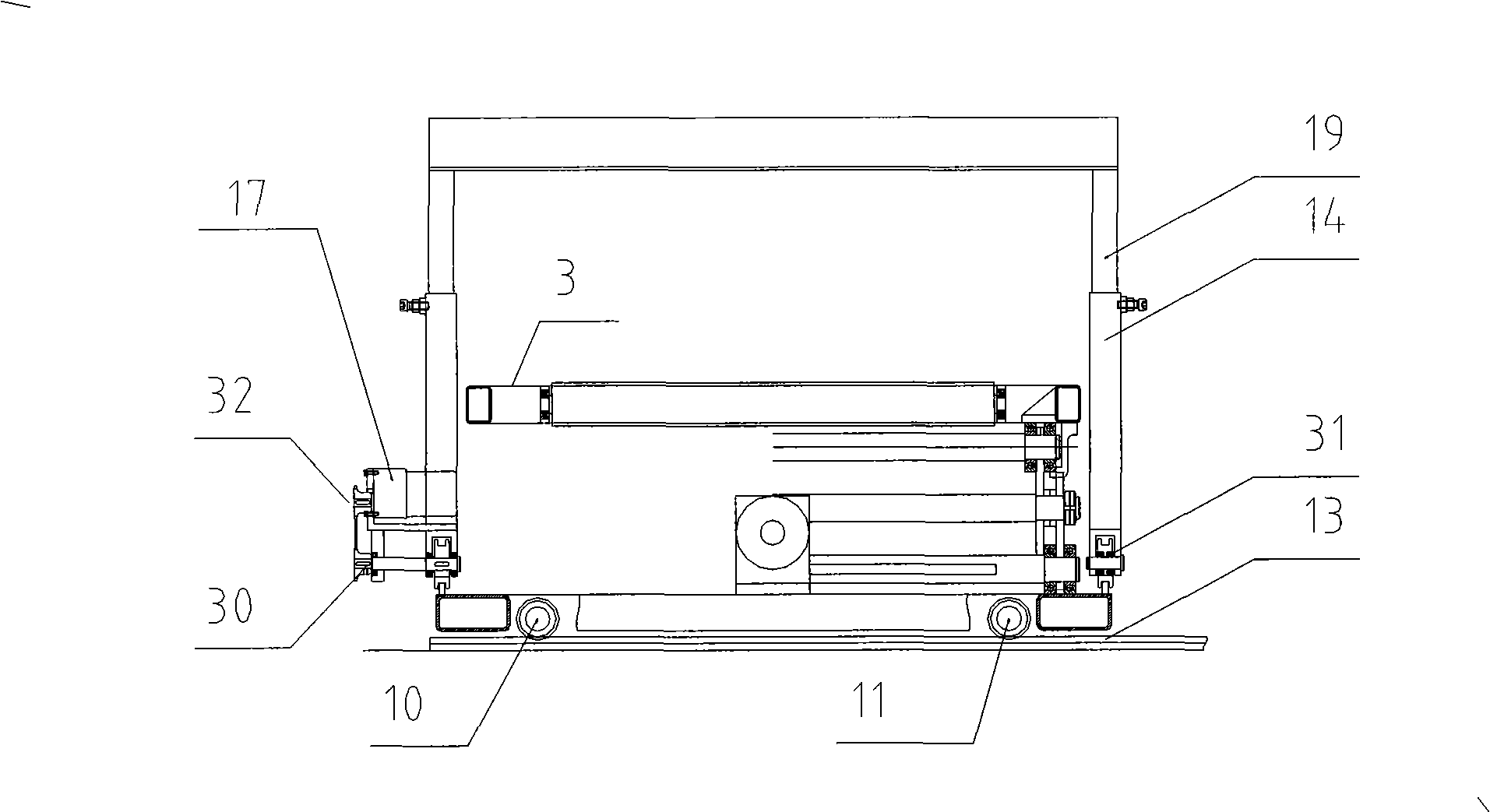

[0023] figure 1 It is a schematic diagram of the side view structure of the multifunctional automatic palletizing conveyor described in the present invention, figure 2 It is a schematic diagram of the transmission part of the multifunctional automatic palletizing conveyor, including the base 1 and the movable platform 2. There is a left lifting arm 26 and a right lifting arm 15 between the base 1 and the movable platform 2. The displacement function box 7 of the handle 25, the manual displacement handle 25 is connected to the displacement execution cylinder 18, the displacement execution cylinder 18 is connected to the base 1 through the cylinder mounting frame 24, and the displacement function box 7 is connected to the flange 6 and the deceleration through the motor The machine 5 is connected, the displacement function box 7 is connected with the left lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com