Asphalt reactor and blending system

A reactor and asphalt technology, applied in mixers, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve problems such as unsuitable modified asphalt, and achieve the effect of reducing internal blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

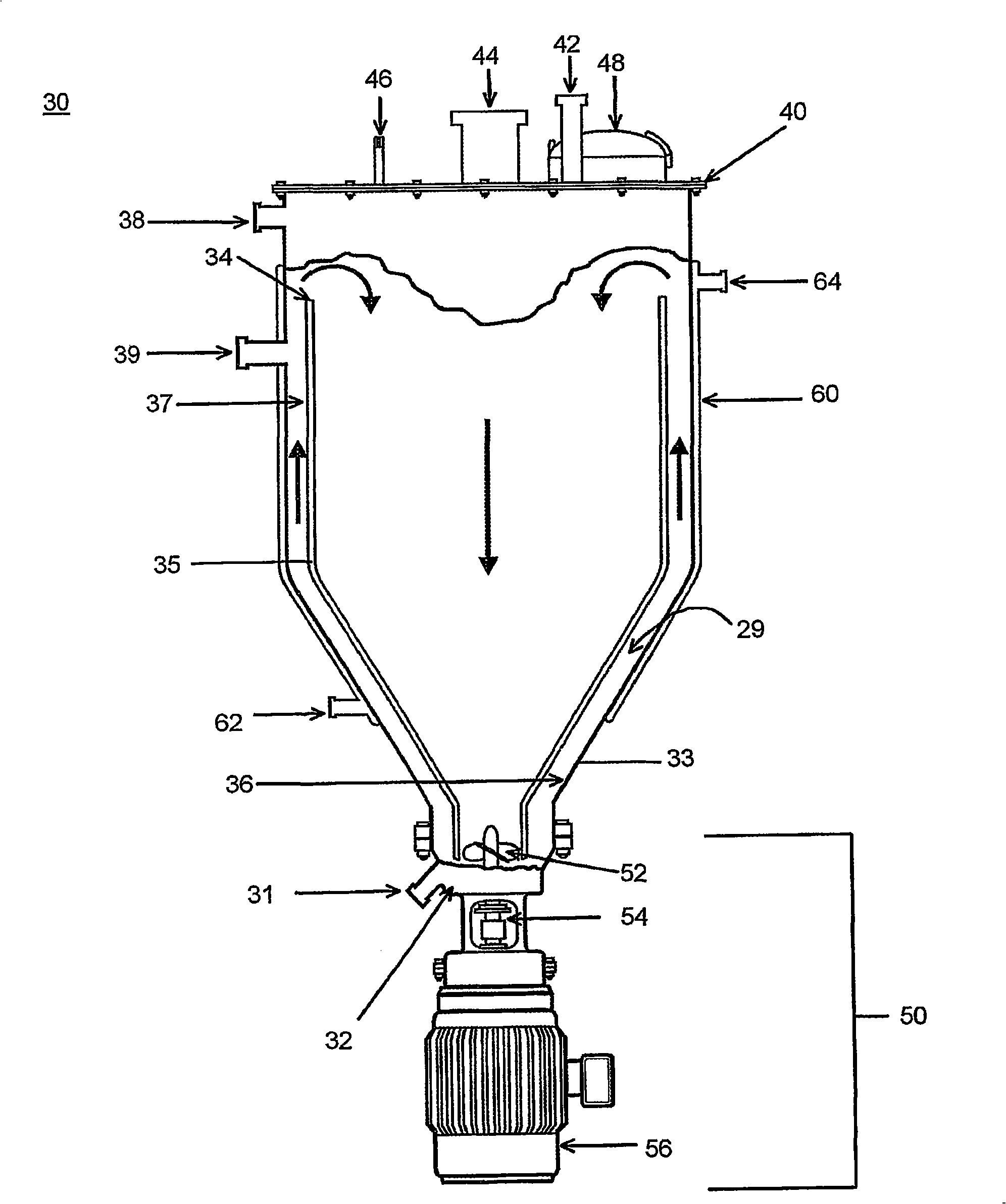

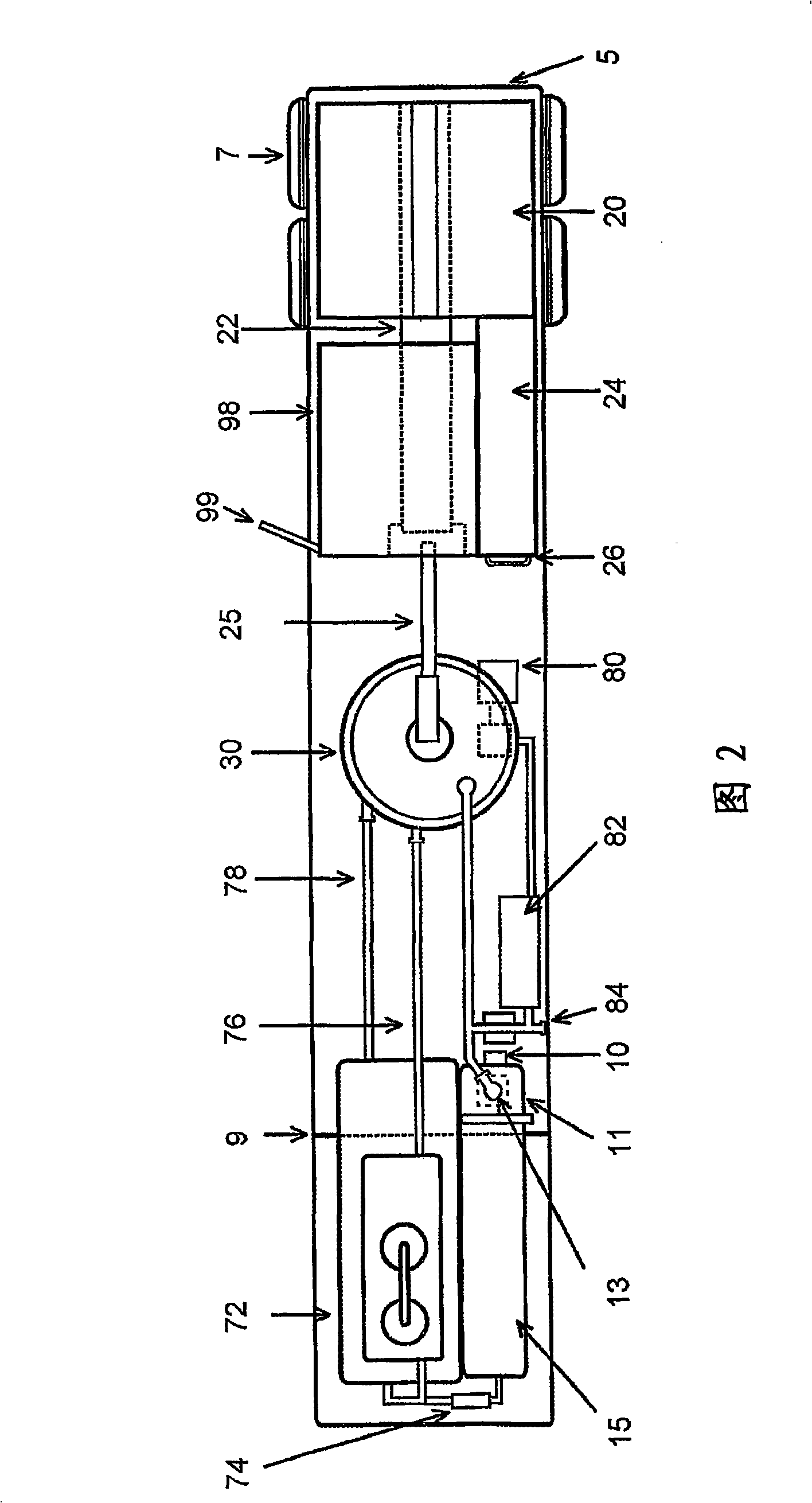

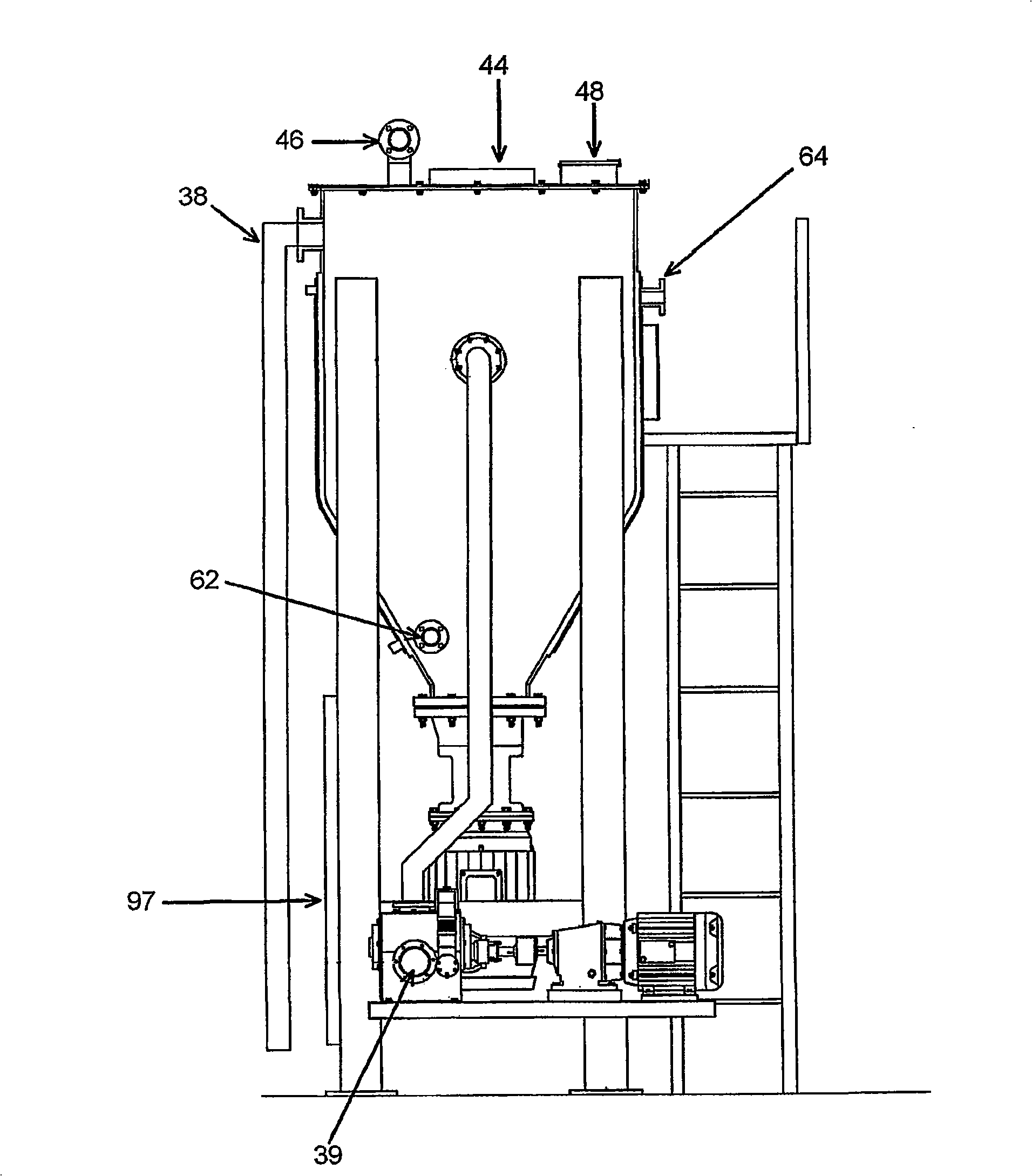

[0062] The main technological process will be described as an example below, figure 1 , 2 and 3 show the ECOPATH TM Devices for mixing systems. Figure 2 specifically shows a preferred embodiment of the invention connected to a single standard trailer 5 with tires 7 and a trailer riser 9 at the front, the trailer 5 can be mounted on its front The lower part (not shown) of the car is connected with a semi-trailer (not shown).

[0063] Shipping raw asphalt binder: The raw asphalt binder can be delivered to the mixing system location using a standard tank truck. The temperature of the asphalt being shipped is typically between about 250°F-300°F. Typical loading volumes for haul trucks are approximately 5,000 to 6,000 gallons. The gear-type positive displacement pump (also known as the asphalt binder pump) 10 in the mixing system can be connected to the discharge connection of the tank truck through a flexible high-temperature hose (also provided by the mixing system) to delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com