Quiet propeller

A propeller, noiseless technology, applied in the direction of rotary propellers, machines/engines, non-variable pumps, etc., can solve problems such as rotational energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

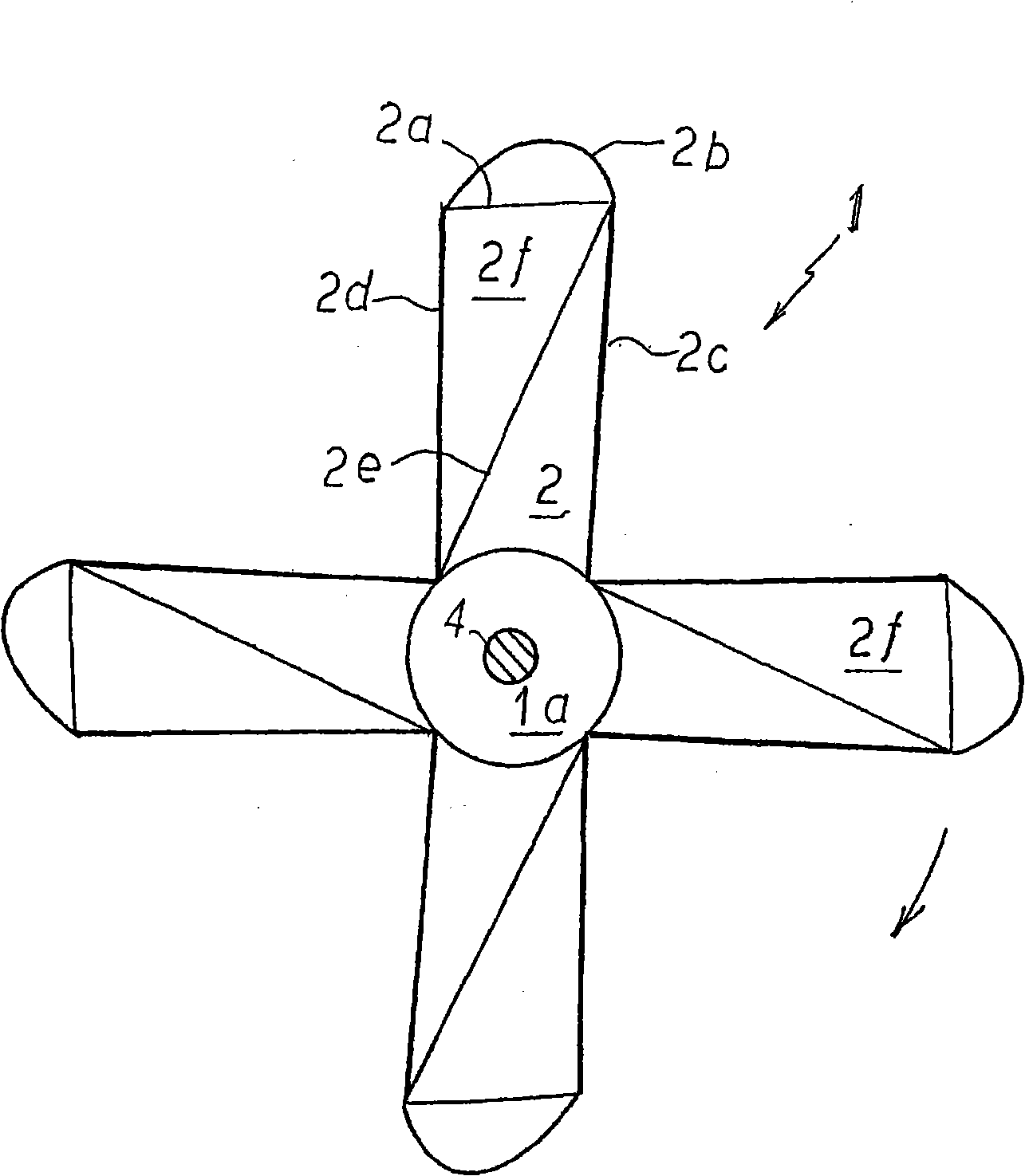

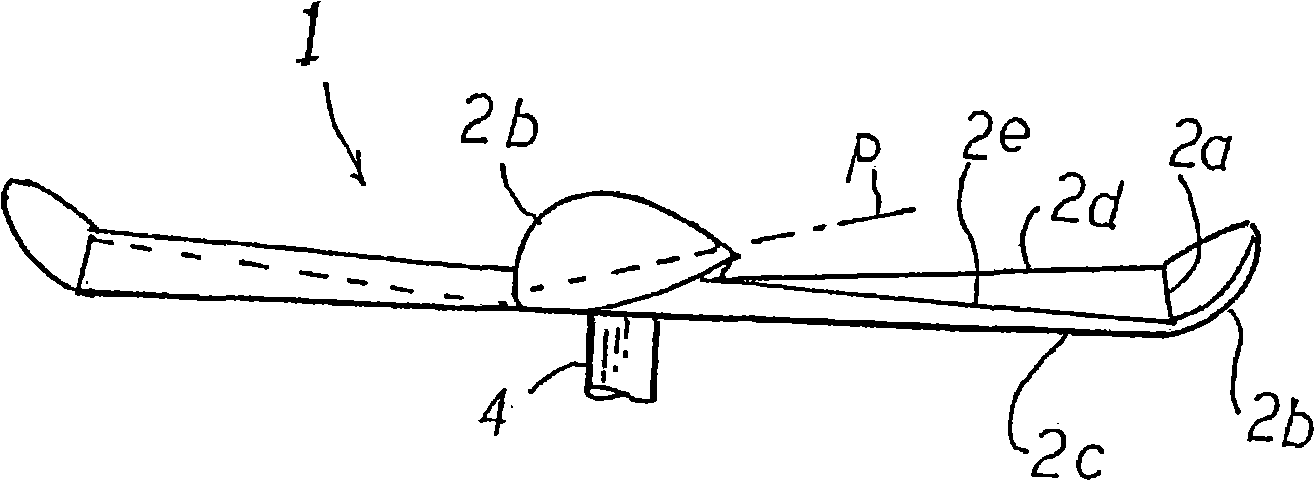

[0035] Embodiments of the present invention will be described below. figure 1 is the rear view of the noiseless thruster according to the present invention, figure 2 is the top plan view. The propeller 1 comprises four propeller blades 2 equally spaced around the punch 1a. The number of propeller blades 2 is not limited to four.

[0036] The base-to-tip lengths of the individual propeller blades 2 are substantially equal to each other. Between the first side 2c and the second side 2d is a bending line 2a.

[0037] From the bending line 2a, a tapered warped end portion 2b is formed.

[0038] The bent end portion 2b is bent from the bending line 2a.

[0039] Depending on the length of the blade 2b, the angle of the warped end 2b can vary between 15° and 45°.

[0040] exist figure 2 Among them, the warped tip 2b is 15% of the blade length, but can vary from 15% to 60%.

[0041] exist figure 1 In , the diagonal line 2e extends from the end of the first side 2c of the bl...

Embodiment approach 2

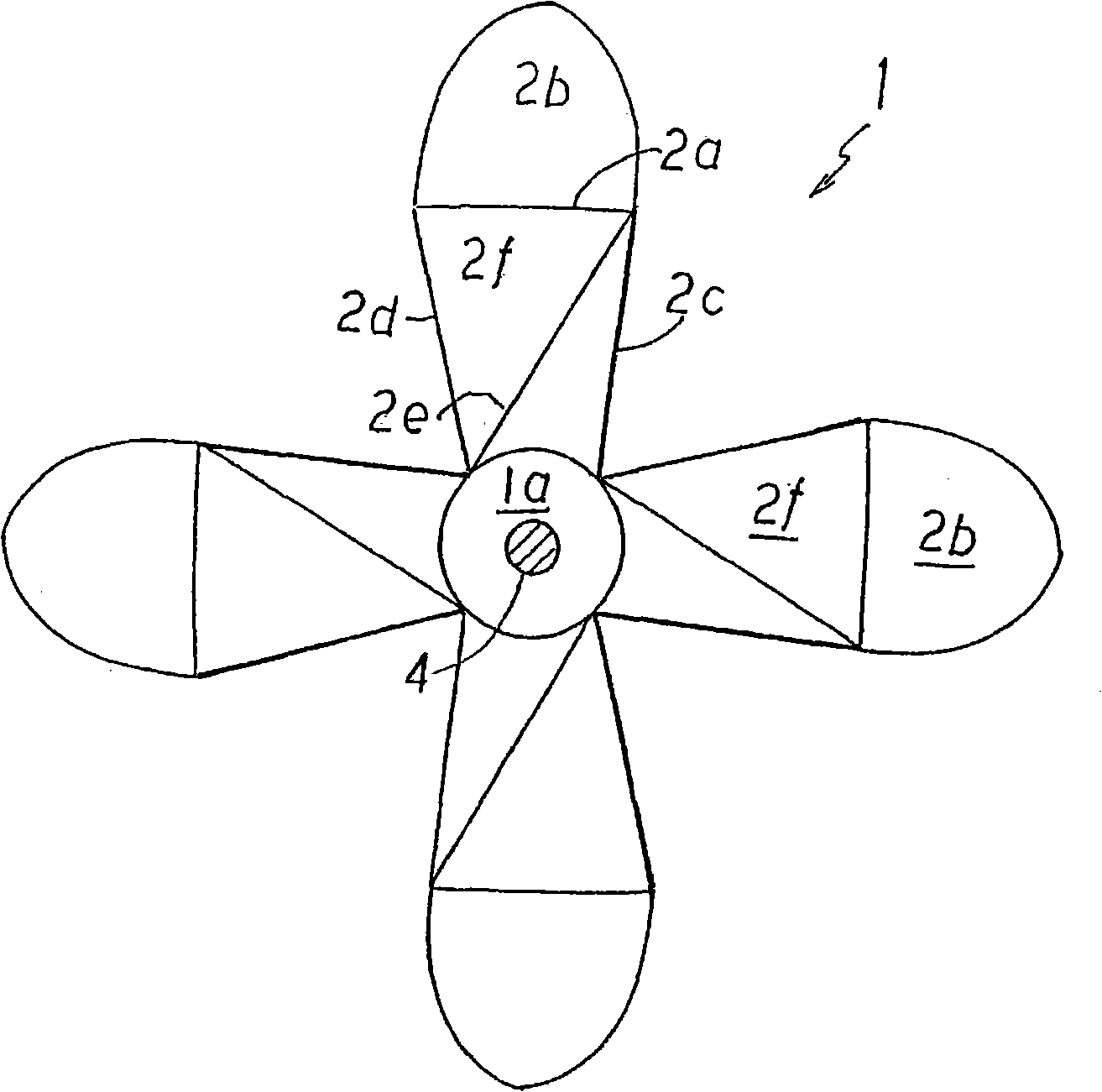

[0054] image 3 is a rear view of a second embodiment of a propeller according to the invention, Figure 4 is its top plan view.

[0055] In the second embodiment, the bending line 2 a of the propeller blade 2 is located at a distance of 40% of the propeller 1 radius from the peripheral end. The length of the warped end 2b is 40% of the length of the blade 2 or the radius of the propeller. But not limited to this.

[0056] The warped rear surface 2f and the warped end portion 2b having the pitch angle P are wider than those of the first embodiment so that the pushing amount of water can be increased. The length of the warped end portion 2 b is set to be 15% to 60% of the length of the blade 2 . If the warped end 2b is longer, the warped angle of the warped end 2b can be smaller.

Embodiment approach 3

[0058] Figure 5 is a rear view of a third embodiment of the thruster, Figure 6 is the top plan view. The description of the same components as those of the previous embodiment denoted by the same reference numerals will be omitted.

[0059] exist Figure 5 In the third embodiment, the distal end of the second side 2d of the propeller blade 2 contacts the bending line 2a. A diagonal line 2e extends from the aforementioned contact point to the proximal end of the first side 2c.

[0060] exist Figure 6 Among them, the first side 2c gradually becomes thinner from the punch 1a to the periphery of the pusher 1 . The propeller blades 2 are warped forward to form a pitch angle P with respect to the diagonal 2e. exist Figure 6 , the pitch angle P is in the range of 7 degrees to 25 degrees.

[0061]In the third embodiment, the pitch angle is not formed close to the center of the propeller 1 . Therefore, in high speed rotation, there is neither cavitation nor eddy current. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com