Water ejector of aircraft carrier

A technology for aircraft carriers and catapults, which is applied in the direction of launch/tow gears, etc., can solve the problems of steam energy utilization rate of only 6%, high cost of steam catapults, low efficiency of steam catapults, etc., so as to achieve the utilization rate of steam energy. High, low cost, the effect of increasing the contact area of soda and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

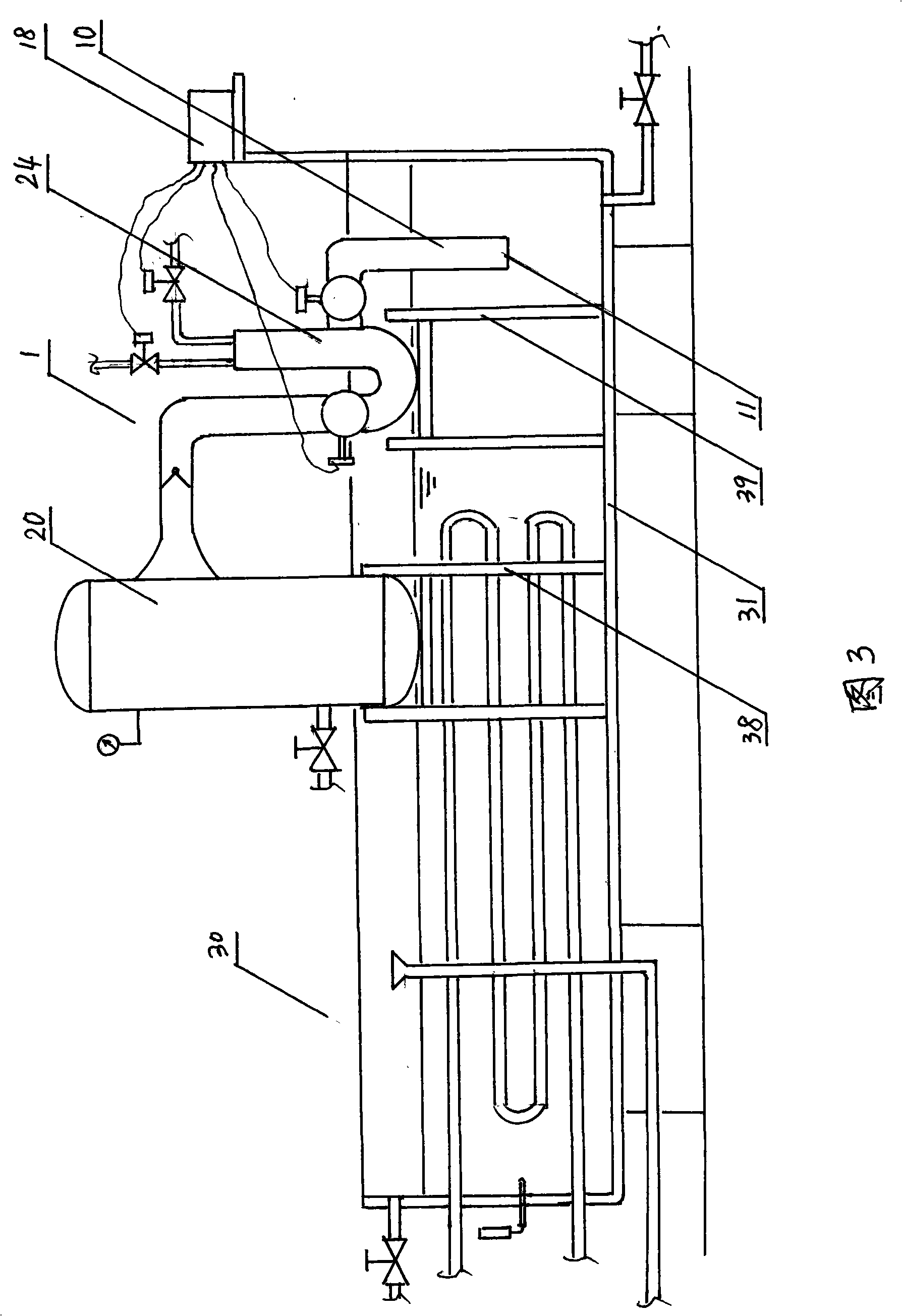

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

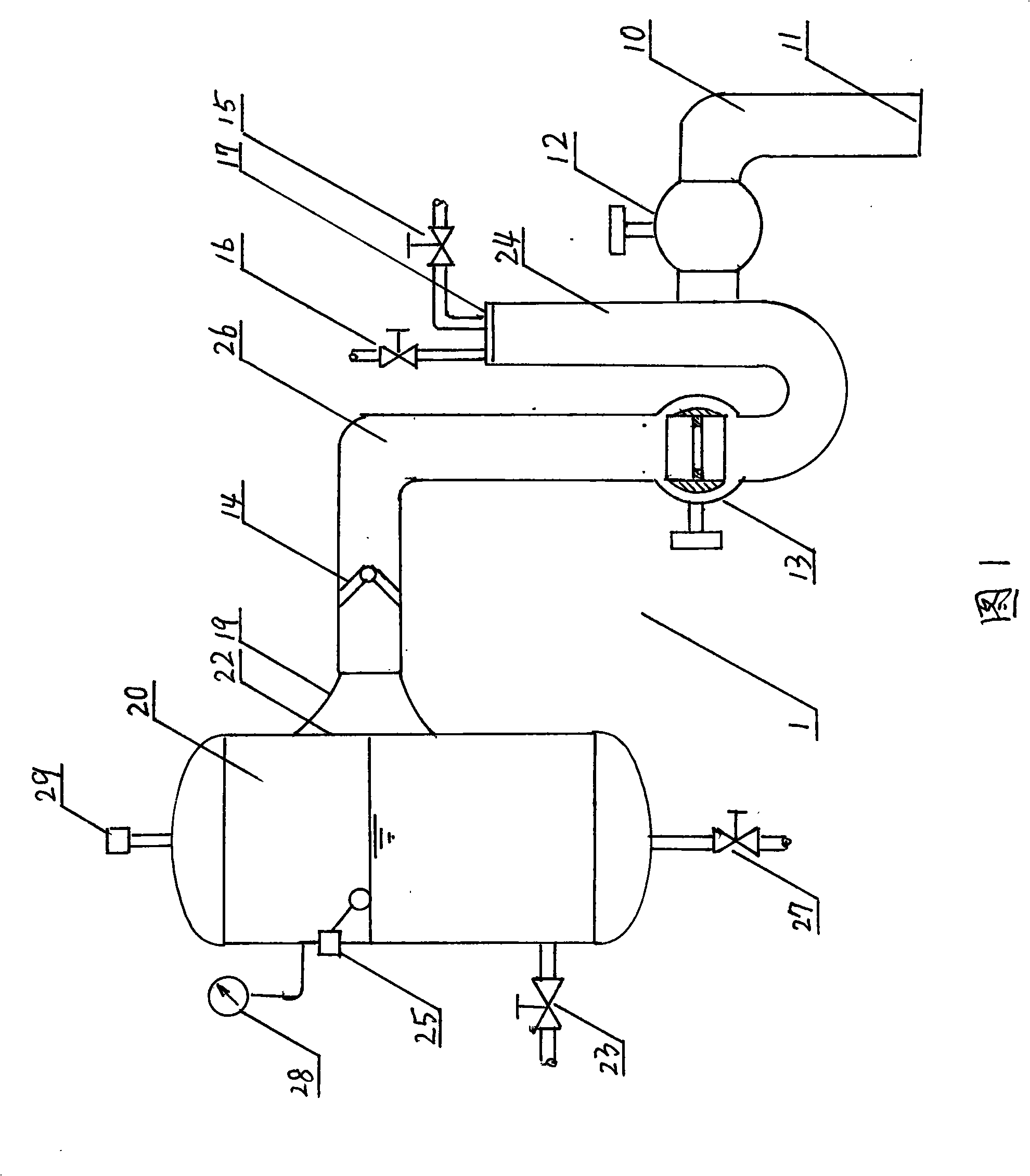

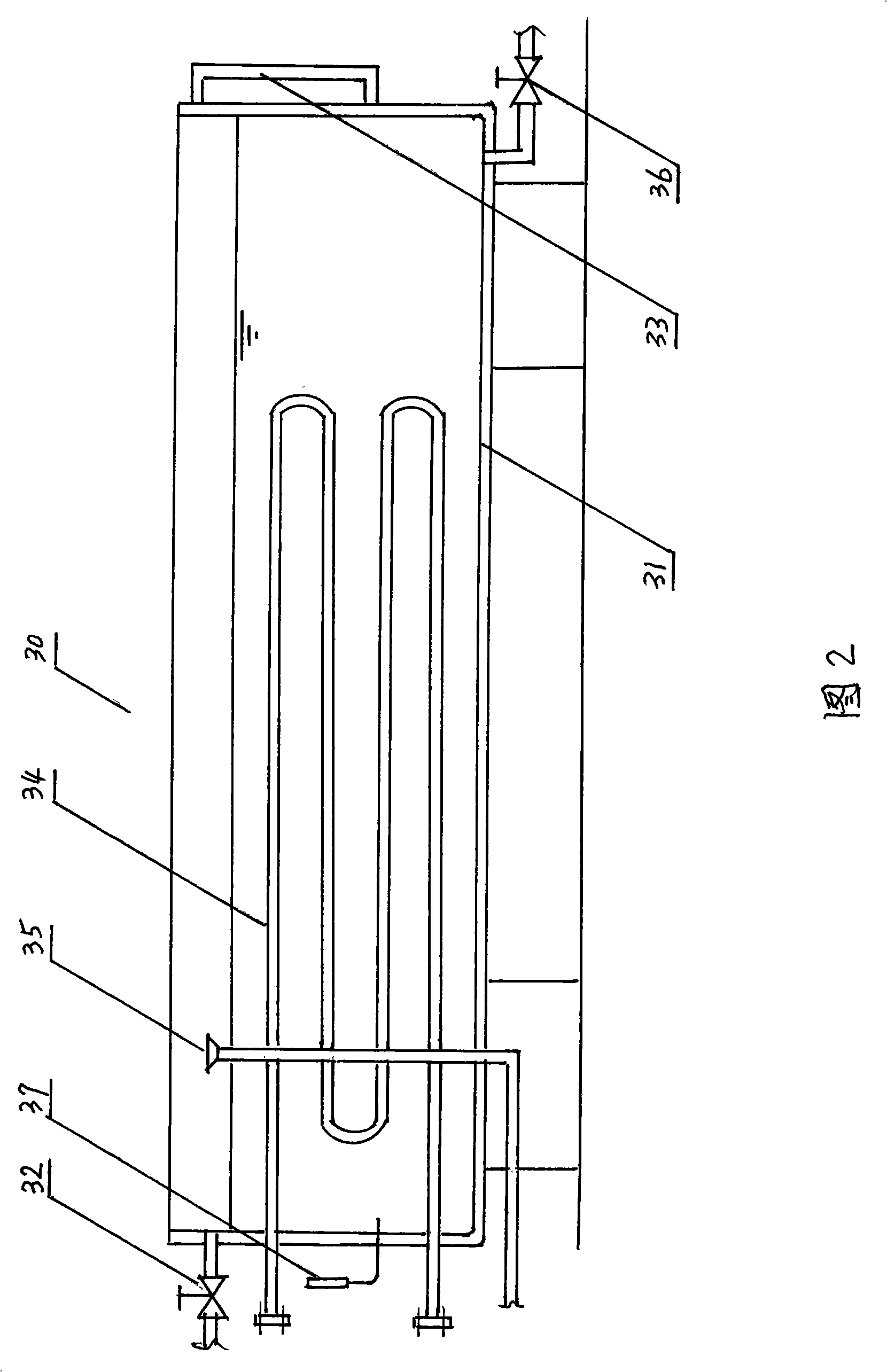

[0082] Fig. 1 is the structural diagram of the steam water feeder of the embodiment of the aircraft carrier hydraulic catapult of the present invention, the steam water feeder is made up of water inlet pipe, steam water pipe, booster pipe and pressure stabilizing tank, wherein, water inlet pipe, steam water pipe, booster pipe are combined again called a transducer.

[0083] The water inlet pipe 10 of the steam water feeder 1 is a right-angle elbow, and its inlet is vertically downwards, which is a water inlet 11. Before the water outlet, a water inlet valve 12 is set.

[0084] The steam water pipe 24 of the steam water feeder 1 is a J-shaped elbow, and the upper end of its vertical section is an inlet, which is closed by an end plate 17 on which an air valve 16 and a steam valve 15 are arranged. The air valve 16 is connected to the air source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com