Regenerative method of processing fluid and reclaiming method of metals contained therein

A technology for treating liquid and recycling pipe, which is applied in the improvement of process efficiency, the manufacture of electrical components, semiconductor/solid-state devices, etc., can solve the problems that the substrate manufacturer cannot easily implement, the transportation cost is high, and the concentration is low, and it is simple and cheap. The effect of low equipment and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

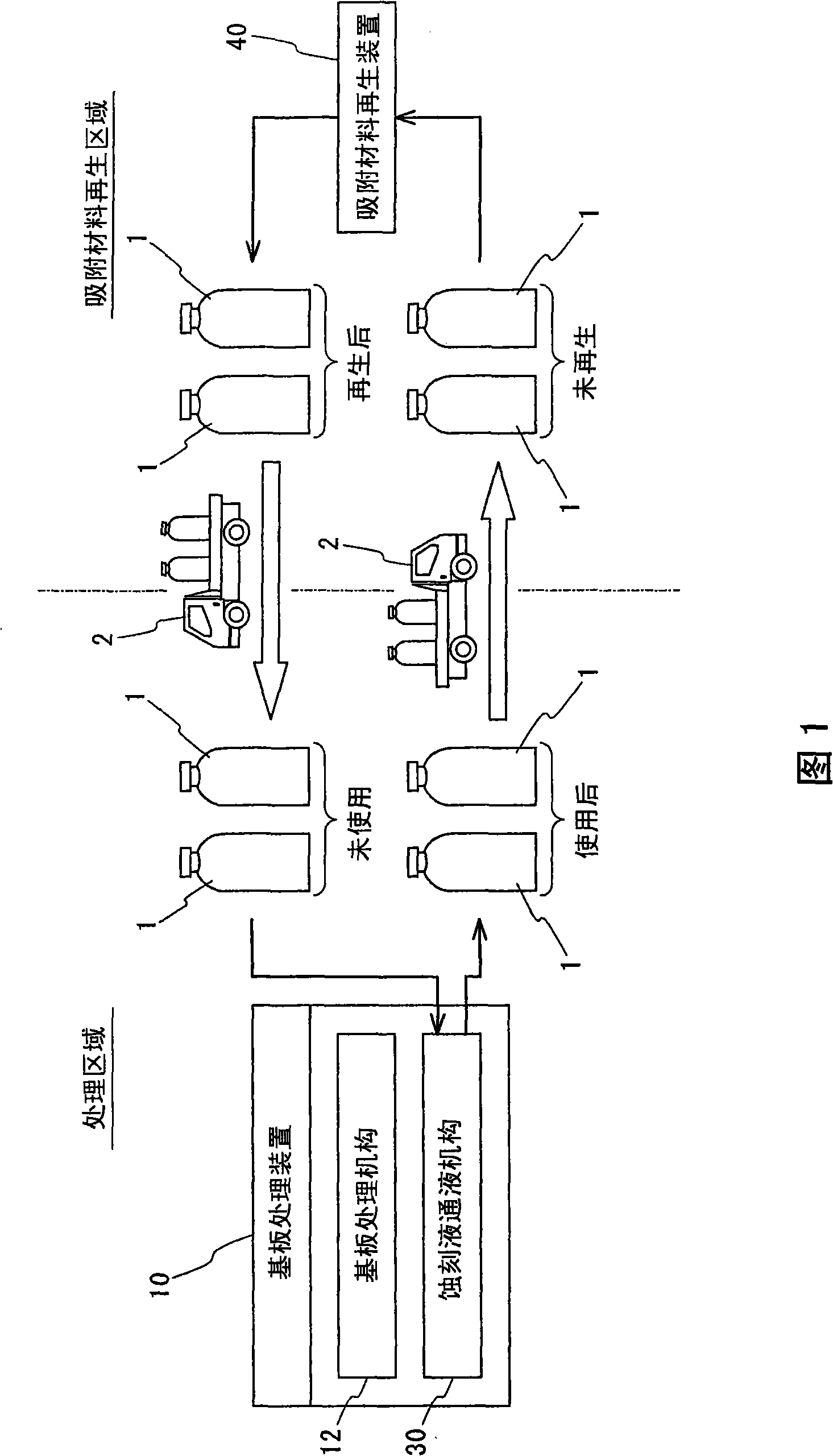

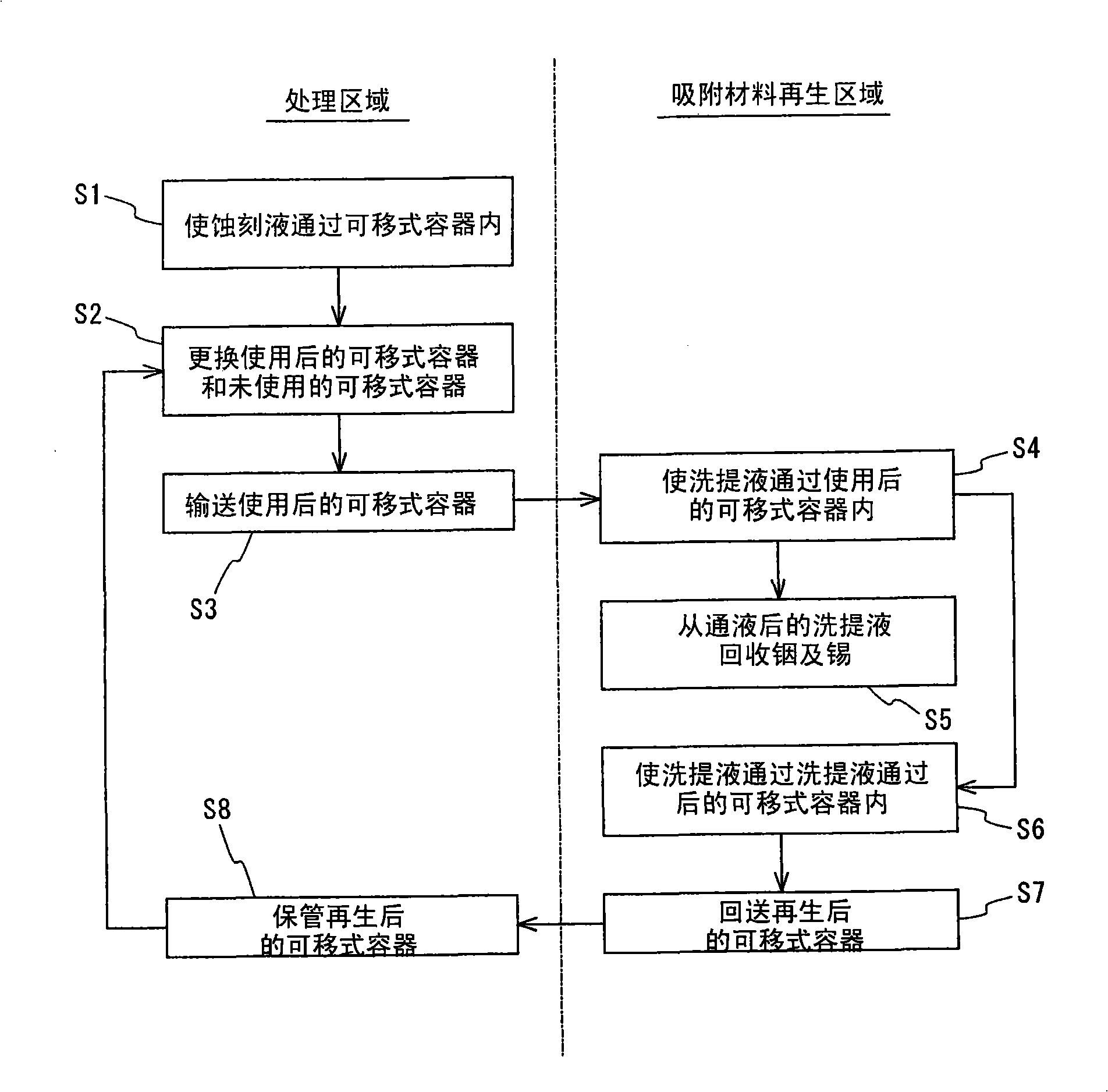

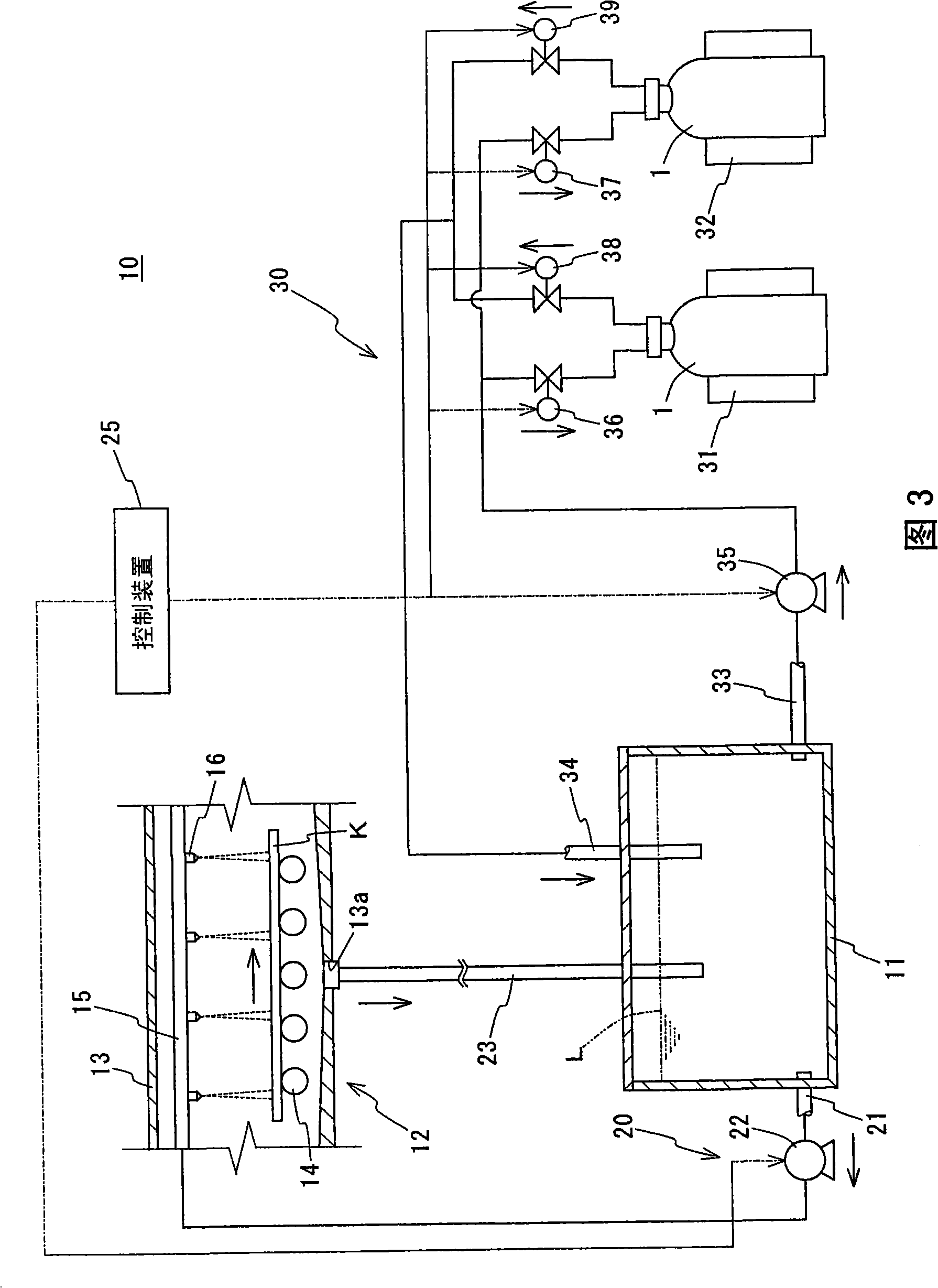

[0050] First, the etching solution regeneration method according to the first embodiment of the present invention will be described based on the drawings. In this first embodiment, a method of regenerating an etching solution containing a metal component by etching a substrate will be described. In addition, FIG. 1 is an explanatory diagram for explaining the etching solution regeneration method according to the first embodiment of the present invention, figure 2 FIG. 3 is a flowchart for explaining a method for regenerating an etching solution according to the first embodiment, and FIG. 3 is an explanatory diagram showing a schematic configuration of a substrate processing apparatus and the like according to the first embodiment. Figure 4 It is an explanatory diagram showing a schematic configuration of an adsorbent regeneration apparatus and the like in the first embodiment.

[0051] First, based on Figure 1, Figure 3 and Figure 4 , the portable container 1 for adsorbing...

no. 2 approach

[0092] Next, the metal recovery method of the second embodiment of the present invention will be described based on the drawings. In the second embodiment, the substrate is etched with the etching solution, and the metal component contained in the etching solution is recovered, and this will be described. 6 is an explanatory diagram for explaining a metal recovery method according to a second embodiment of the present invention, Figure 7 It is a flowchart for demonstrating the metal recovery method of 2nd Embodiment.

[0093] Also, as shown in Figure 3 and Figure 4 and Figure 6 and Figure 7 As shown, the movable container 1 has the same structure as described above except that it can be attached to and detached from the substrate processing apparatus 10 and the metal recovery apparatus 70 for recovering the metal dissolved in the etching solution L. In addition, the metal recovery device 70 is provided with the Figure 4 The illustrated adsorbent regeneration device 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com