Embedded type stone material cellular compound plate dried hanging structure

A honeycomb composite panel, embedded technology, applied in building construction, covering/lining, construction, etc., can solve the problem of insufficient honeycomb panels, and achieve the effect of improving reliability, overcoming insufficient self-strength, and reducing the risk of accidental peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

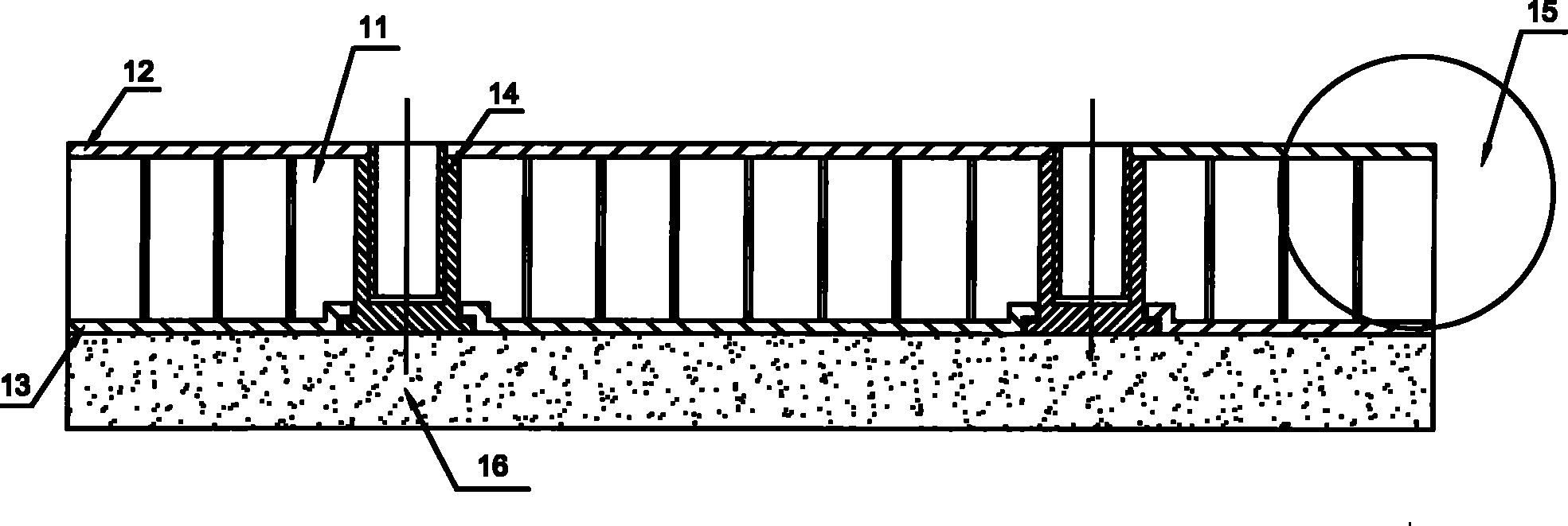

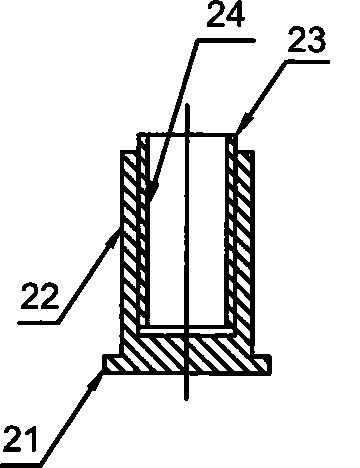

[0019] now refer to Figure 1-Figure 4 The present invention is described. As mentioned above, the purpose of the present invention is to propose a technical solution to solve the above problems, thereby improving the reliability of dry-hanging stone honeycomb composite panels and reducing the risk of accidental peeling of stone honeycomb composite panels affected by the natural environment.

[0020] The dry-hanging structure of the embedded stone honeycomb composite panel provided by the present invention will be described in detail below. refer to figure 1 The embedded stone honeycomb composite panel dry-hanging structure includes a core material 11, a metal plate 12 attached to one surface of the core material 11, and another surface attached to the core material 11 (with the attached metal plate 12). The metal plate 13 provided with the counterbore on the surface opposite to the surface) and the metal plate 12 and the metal plate 13 provided with the counterbore are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com