Field hole-digging and pouring foundation pit concrete support pile structure and manufacturing method thereof

A technology of concrete and support piles, which is applied in basic structure engineering, excavation, construction, etc., and can solve the problems of insufficient strength of a single concrete support pile, enhance bending stiffness, bending bearing capacity and deformation resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

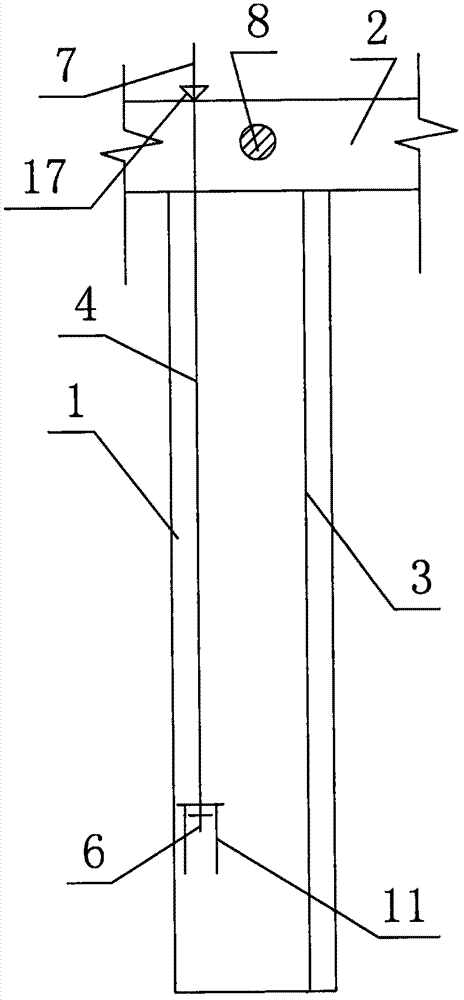

[0053] The specific embodiment of the foundation pit concrete support pile structure manufacturing method of on-site digging and pouring of the present invention is as follows:

[0054] Excavating the pile hole according to the routine is as adopting drilling rig drilling, and the mud in the mud pool that prepares in advance is about to be pressed into the drilled hole to prevent the hole wall from collapsing.

[0055] Making the support pile reinforcement cage 5:

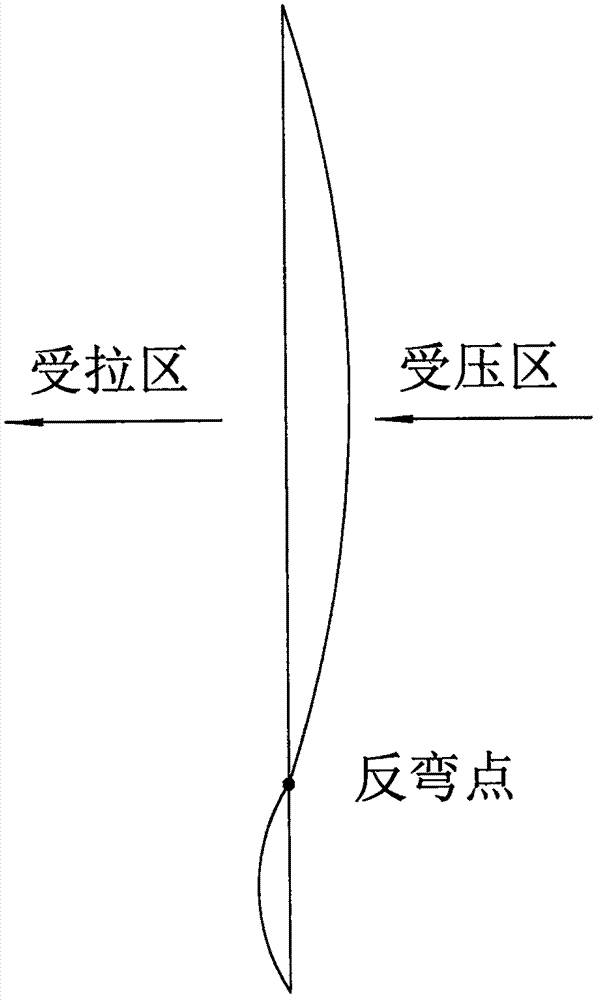

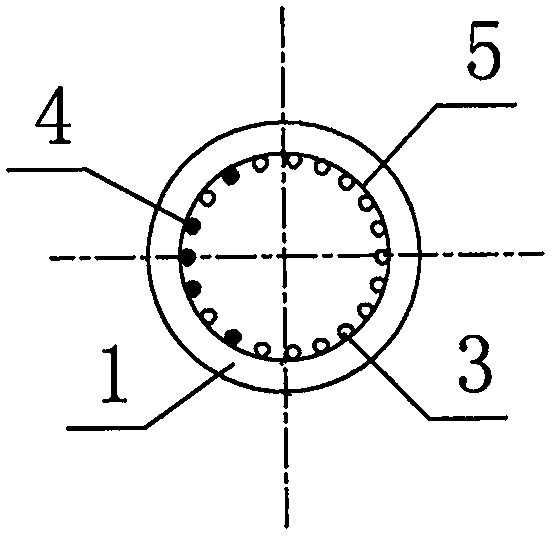

[0056] The cross-section of the reinforcement cage of the concrete support pile is set as a circle, and the vertically extending non-stress tendons 3 and the reinforcement cage 5 are kidnapped and fixed.

[0057] Each post-tensioned prestressed steel bar 4 is covered with a PVC sleeve whose inner diameter is larger than the outer diameter of the prestressed steel bar of the support pile, that is, a nominal diameter of 3-4 mm.

[0058] Make the pressure bearing plate 10 connected with the post-tensioned prestressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com