A powdered coal forming, drying and dry distillation integrated molding coke process

A technology of drying and pulverizing coal, which is applied in the direction of special dry distillation, direct heating dry distillation, combustible gas purification, etc. It can solve the problems of large deformation and powder loss, reduced mold coke yield, and complicated process control, so as to reduce the mixing Uniformity requirements, segmental control and easy arrangement, and the effect of improving the uniformity of dry distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

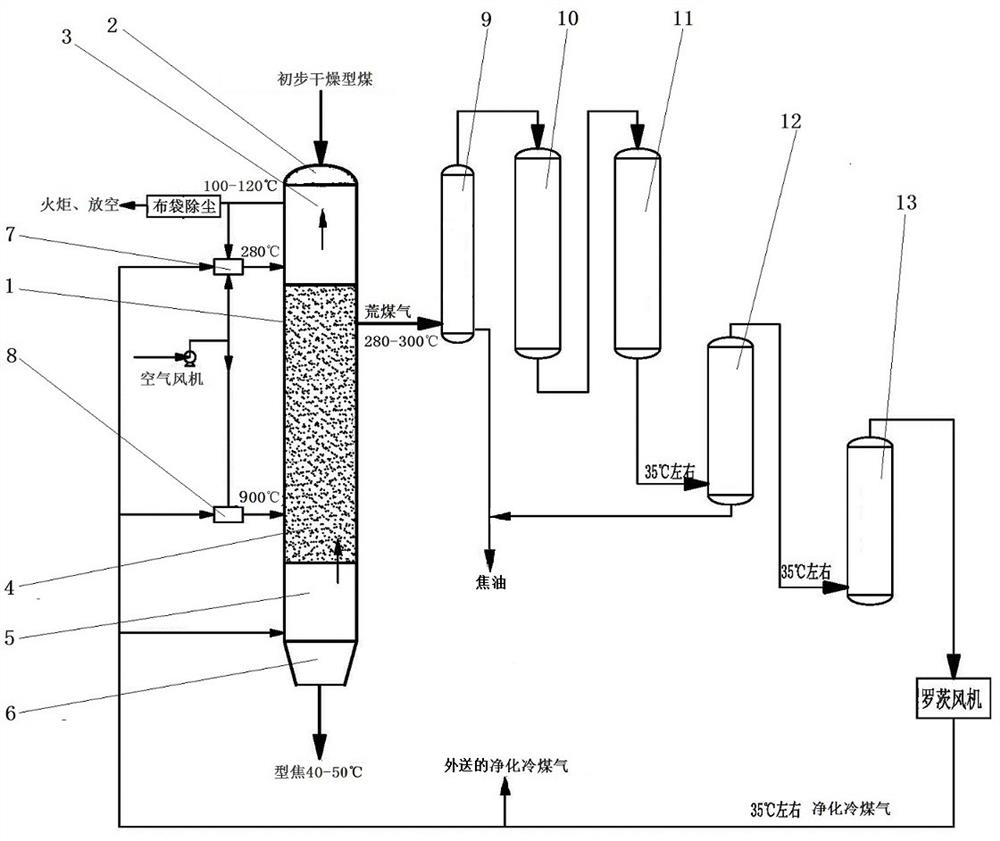

[0038] In a set of coke production equipment, the three kinds of pulverized coal raw materials listed in Table 1 are mixed according to the mass ratio of 30% fat coal powder + 60% Shenmu pulverized coal + 10% anthracite pulverized coal, and the coal is mixed evenly by the mixer. , add an appropriate amount of water to moisten and mix until the total moisture content is about 16%; the mixed coal powder is sent to a molding machine to be pressed into a spherical briquette, and the molding pressure is 18MPa; the fat coal powder is strongly cohesive bituminous coal Powder, Shenmu pulverized coal, and anthracite coal are not cohesive, and Shenmu pulverized coal belongs to long-flame coal. The coal briquettes are initially dried in a belt dryer at 130°C, and then in the attached figure 1 The dry distillation process system shown is deep drying, dry distillation, coke quenching, coke preparation, and by-products of gas and tar.

[0039] attached figure 1 The carbonization process s...

Embodiment 2

[0056] In the coke production device of Example 1, the other conditions remain unchanged, the difference is that a small amount of coke powder by-product of the device is used in the coal blending process, and the specific mass ratio is 30% of fat coal powder + 50% of Shenmu pulverized coal + coke powder 10% + anthracite powder 10%.

[0057] The coke production device was continuously produced for 5 days according to the above conditions, and the average production capacity was 13t / h. It was found that the quality of the coke was good, the uniformity of dry distillation and the consistency of coking were good, and the deformation, fragmentation rate and powder loss of the coke were relatively good. The volume and air resistance of the material layer are low.

Embodiment 3

[0059] In the coke production device of Example 1, the rest of the conditions remain the same, the difference is that brown coal powder is used to replace Shenmu pulverized coal in coal blending, and the specific mass ratio is 30% fat coal powder + 60% lignite powder + 10% anthracite powder, dry distillation The temperature of the hot air flow generated by the hot air burner and transported to the bottom of the dry distillation section is reduced to 700°C. The typical physical and chemical indicators of the lignite powder used are listed in Table 3.

[0060] Table 3 Typical physical and chemical indicators of lignite powder

[0061] .

[0062] Continuously produced for 20 days under the stated conditions, the average production capacity was 12t / h of molded coke. It was found that the quality of molded coke was good, the uniformity of dry distillation and coking consistency were good, and the deformation, fragmentation rate, powder loss and material layer of molded coke Air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com