Construction method for leveling top surface of bearing during second-time beam lowering after jacking

A construction method and top technology, applied in the direction of bridge, bridge maintenance, bridge reinforcement, etc., can solve the problems of unsafe bridge, unstable structure, weak bonding between steel plate and steel plate, etc., to ensure the overall stress of the bearing, The effect of prolonging the service life and reducing the risk of bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

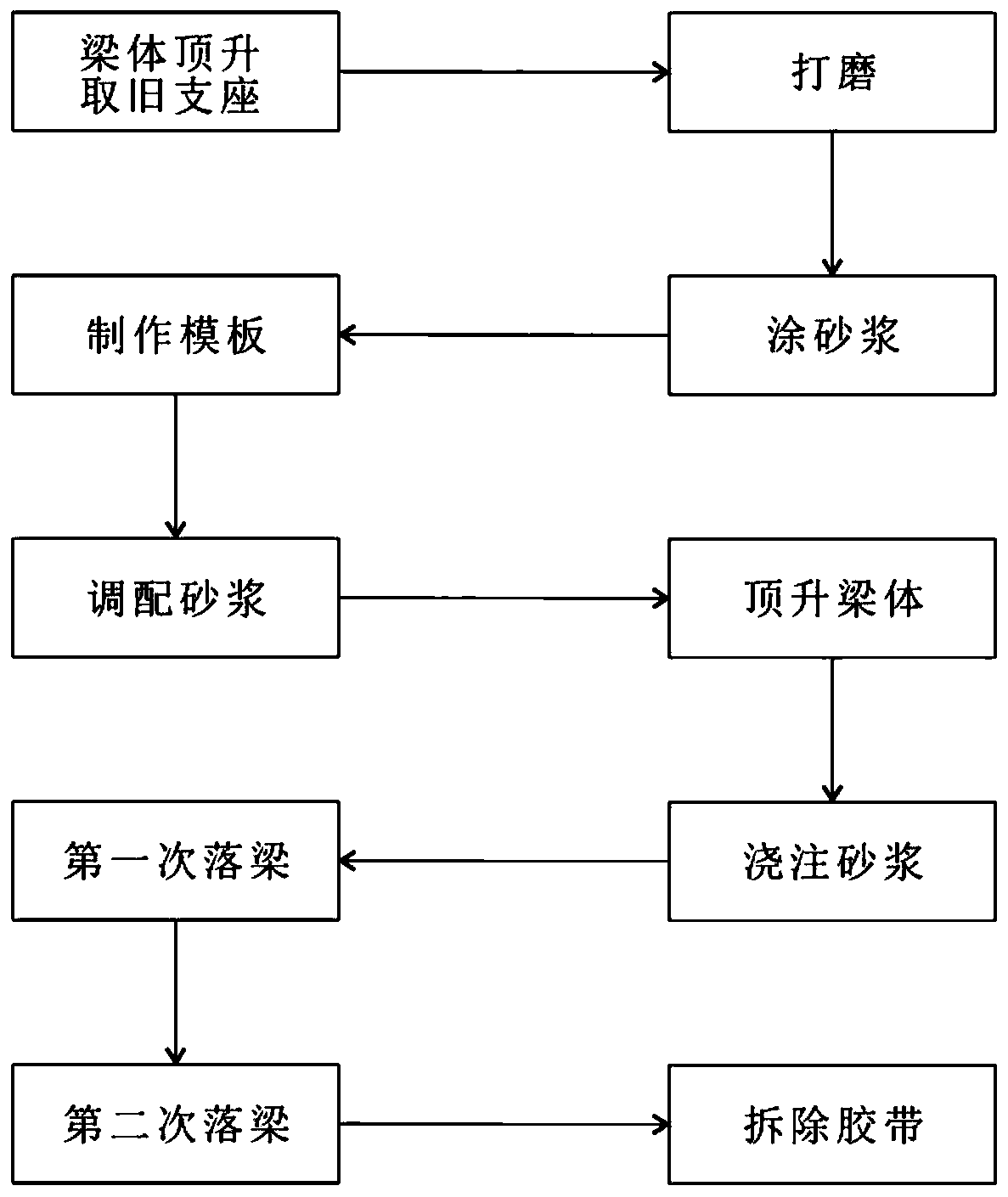

[0029] Such as figure 1 Shown is a flow chart of the present invention,

[0030] In this embodiment, the replacement of road bridge bearings on the section from Chengdu to Nanchong is taken as an example: the construction will be carried out in June, and the specific operation is a construction method for leveling the top surface of the beam bearings for the second time after lifting, which includes the following steps:

[0031] S1. Use a fully automatic jacking system to lift the entire beam body to 10mm, and take out the old support. Specifically, the construction personnel determine the jacking height according to the actual situation on site and make fine adjustments. It may not be necessary to jack up to 10mm, and the old support can be taken out, or it may be necessary to jack up to more than 10mm, before the old support can be taken out. The smaller the jacking height, the safer the bridge.

[0032] S2. Construction personnel use angle grinder to grind, grind the top ...

Embodiment 2

[0043] In this embodiment, the replacement of road bridge bearings on the section from Chengdu to Nanchong is taken as an example: the construction will be carried out in October, and the specific operation is a construction method for leveling the top surface of the beam bearing for the second time after lifting, which includes the following steps:

[0044] S1. Use automatic jacking equipment to lift the whole beam body to a suitable height, and take out the old support;

[0045] S2. Use an angle grinder to grind the top surface of the support pad stone and the bottom of the beam, and remove loose concrete;

[0046] S3, coat epoxy mortar on the top of the pad stone to make the top surface of the pad stone smooth;

[0047] S4. Use adhesive tape to wrap around the support and protrude from the top surface of the support by 10mm, form a template with a height of 10mm on the top surface of the support, and cut an opening at the top of the four corners of the template;

[0048] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com