A microcarrier for increasing the culture density of nitrifying bacteria and its preparation method

A technology of nitrifying bacteria and culture density, applied in the field of environmental microorganisms, can solve the problems of poor sludge properties, complex components, and many refractory pollutants, and achieve the effects of improved structural stability, moderate size, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

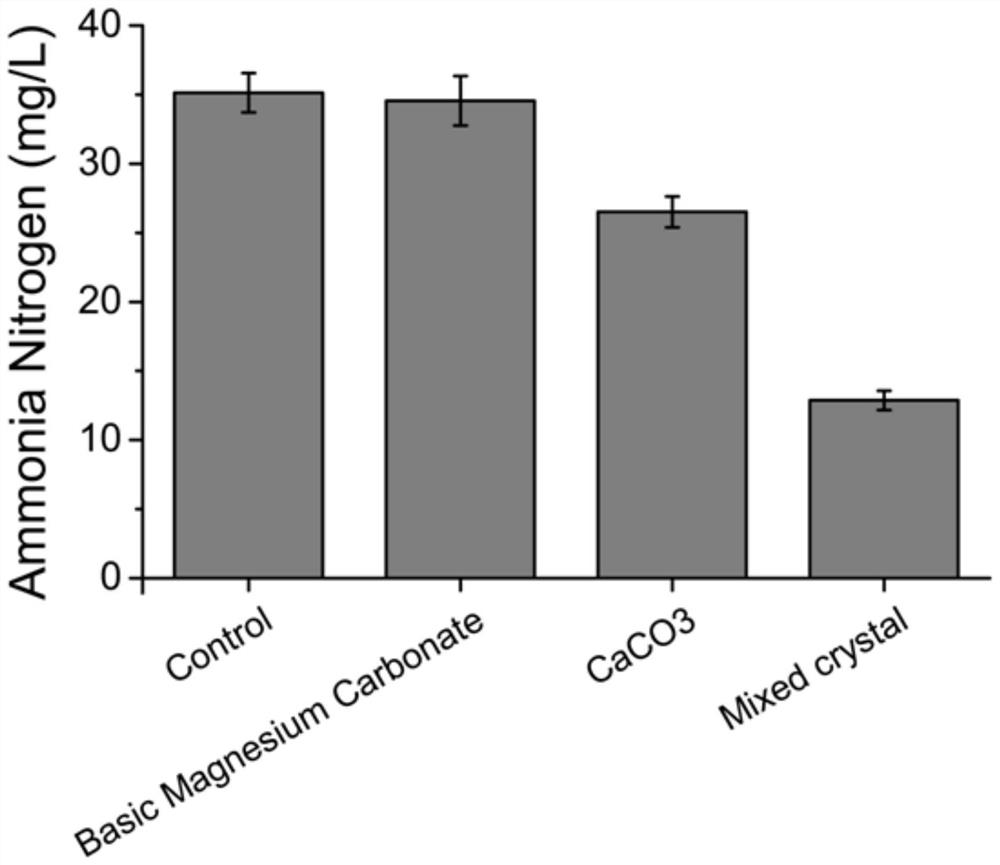

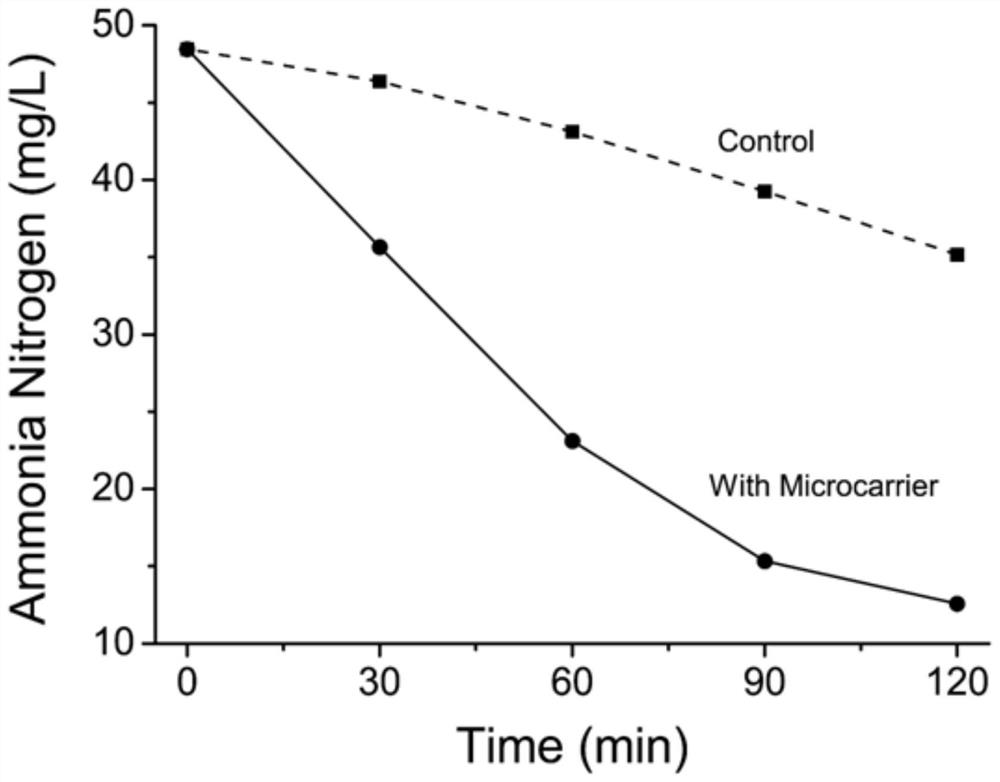

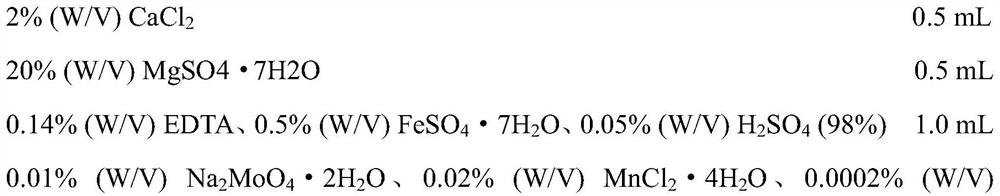

Embodiment 1

[0015] The prepared microcarrier for improving the culture density of nitrifying bacteria in the present embodiment is a calcium carbonate microcarrier, and the specific preparation method is as follows: prepare 0.1mol / L Na 2 CO 3 solution, 0.1mol / L CaCl 2 Each solution was 200mL, and 25mL of 0.5g / L PAA solution was added to Na 2 CO 3 solution and CaCl 2 In the solution, stir at low speed for 0.5h. Add the SDS solution only to the Na 2 CO 3 In the flask of the mixed solution of PAA and SDS, the final concentration of SDS was 10 mM. Adjust the speed to 200r / min, put CaCl 2 The mixed solution with PAA was quickly poured into the three-necked flask, and the reaction was maintained for 1 hour at 50° C. and a rotational speed of 200 r / min. The resulting CaCO 3 The product was filtered, washed twice with deionized water and absolute ethanol, and dried in a vacuum oven at 80°C for 24 hours to obtain CaCO 3 Microcarriers.

[0016] The microcarriers prepared in this example ...

Embodiment 2

[0025] The microcarriers prepared in this example to improve the culture density of nitrifying bacteria are calcium carbonate and basic magnesium carbonate mixed crystal microcarriers. The specific preparation method is as follows: prepare 0.1mol / L of Na 2 CO 3 Solution 200mL, 0.05mol / L CaCl 2 and MgCl 2 Each solution 100mL, CaCl 2 and MgCl 2 The solutions were mixed, and 25 mL of 0.5 g / L PAA solution was added to Na 2 CO 3 solution and CaCl 2 mixed MgCl 2 In the solution, stir at low speed for 0.5h. Add the SDS solution only to the Na 2 CO 3 In the flask of the mixed solution of PAA and SDS, the final concentration of SDS was 20 mM. Adjust the speed to 200r / min, put CaCl 2 The mixed solution with PAA was quickly poured into the three-necked flask, and the reaction was maintained for 1 hour at 50° C. and a rotational speed of 200 r / min. The resulting precipitated product was filtered, washed twice with deionized water and absolute ethanol, and dried in a vacuum oven ...

Embodiment 3

[0030] The microcarriers prepared in this example to improve the culture density of nitrifying bacteria are calcium carbonate and basic magnesium carbonate mixed crystal microcarriers. The specific preparation method is as follows: prepare 0.1mol / L of Na 2 CO 3 Solution 200mL, 0.02mol / L CaCl 2 and 0.08mol / L MgCl 2 Each solution 100mL, CaCl 2 and MgCl 2 Mix the solution, add 25mL of 1.5g / L PAA solution to Na 2 CO 3 solution and CaCl 2 +MgCl 2 In the mixed solution, stir at low speed for 0.5h. Add the SDS solution only to the Na 2 CO 3 In the flask of the mixed solution with PAA, the final concentration of SDS was 15 mM. Adjust the speed to 200r / min, put CaCl 2 The mixed solution with PAA was quickly poured into the three-necked flask, and the reaction was maintained for 1 hour at 70° C. and a rotation speed of 200 r / min. The resulting precipitated product was filtered, washed twice with deionized water and absolute ethanol, and dried in a vacuum oven at 80° C. for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com