Image sensor and method for forming the same

An image sensor and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as affecting the performance of pixel units, reducing the effective area of photodiodes, etc., to achieve the effect of performance assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

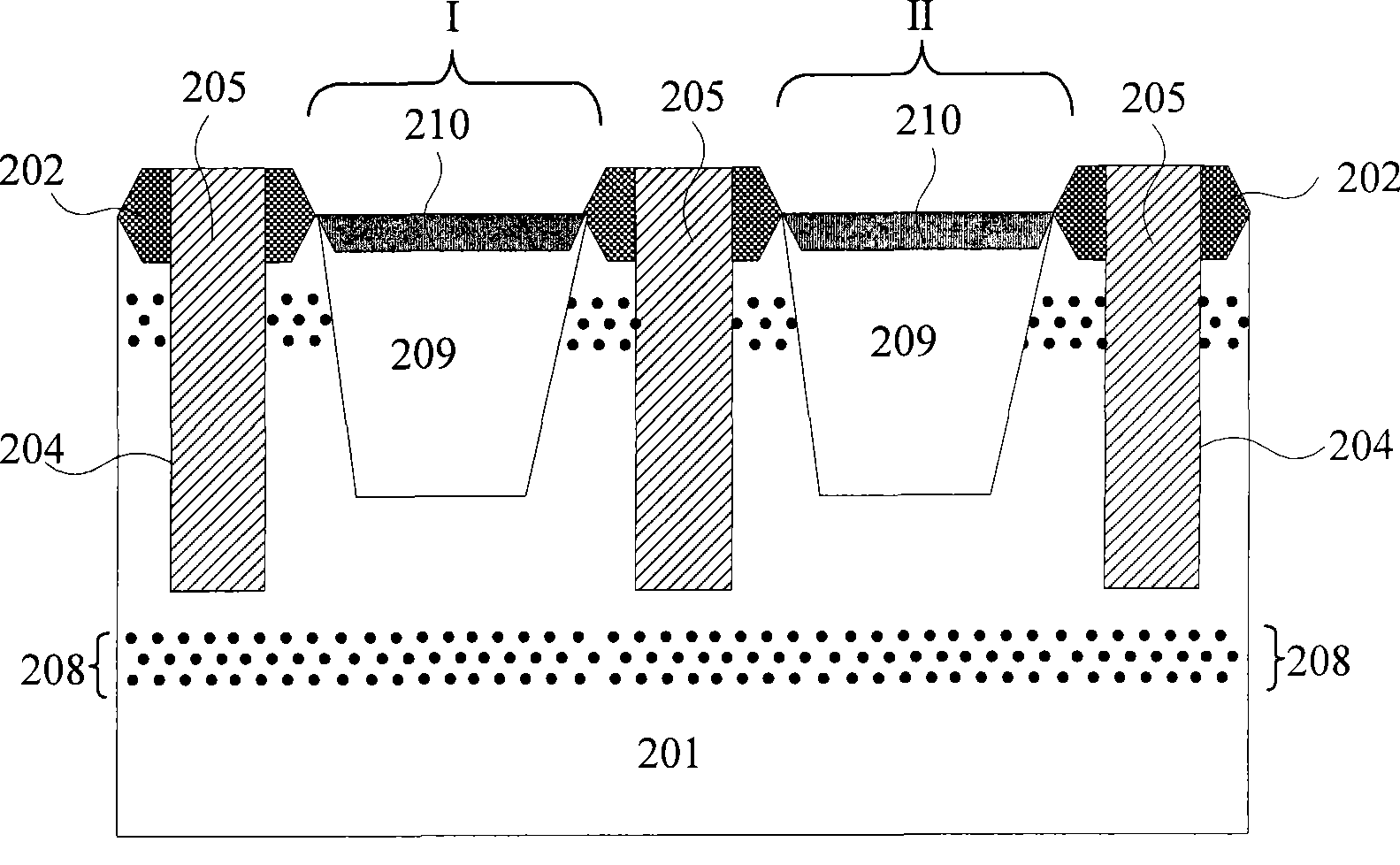

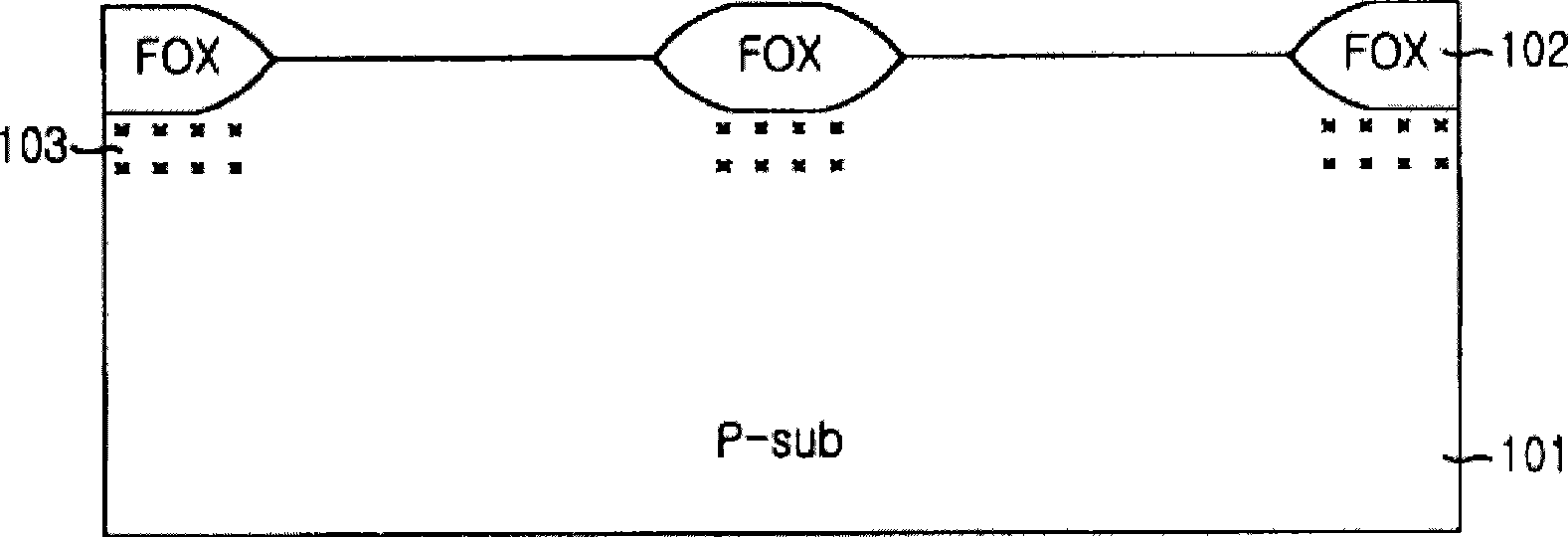

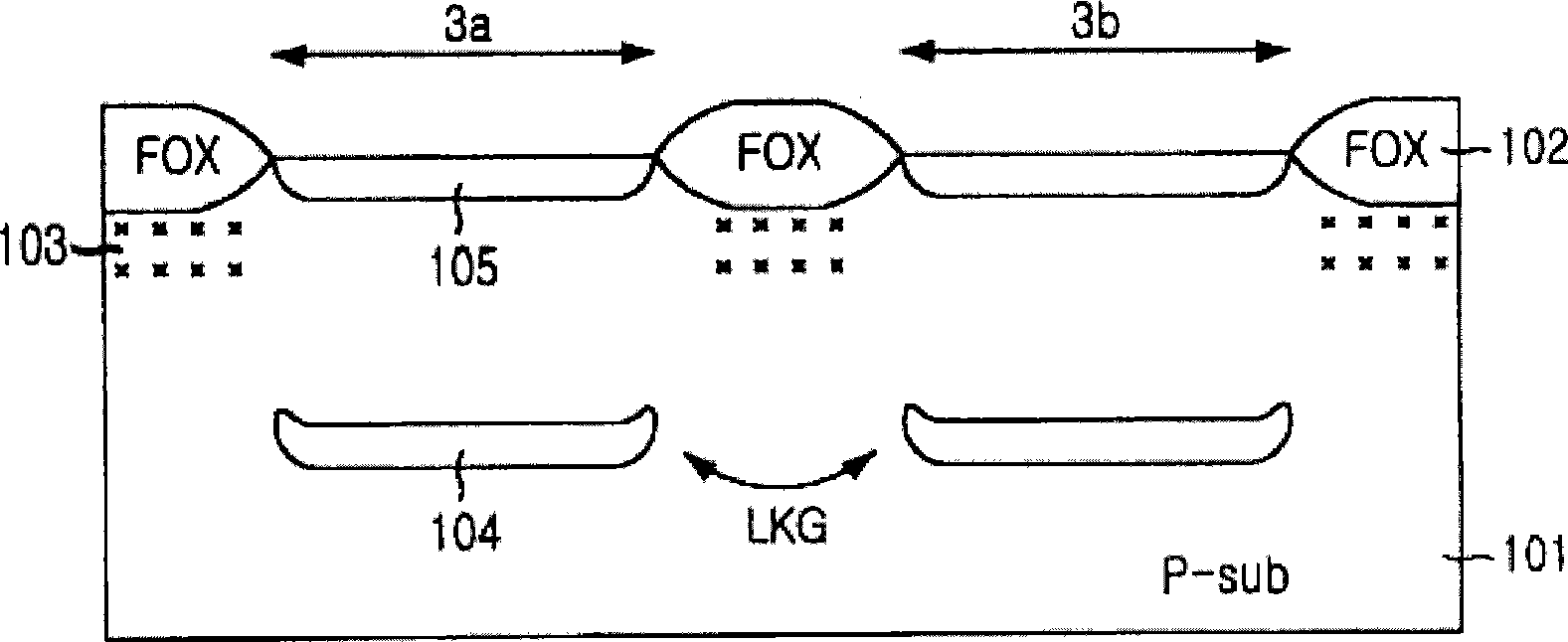

[0031] The present invention provides an image sensor that uses trenches to isolate adjacent photodiode regions. The present invention uses a deep trench to isolate the image sensor, and the deep trench runs through the device isolation layer, and the bottom of the deep trench is located under the first doped well of the photodiode, which can effectively prevent the photodiode region of the adjacent pixel unit region from generating The leakage current, meanwhile, does not reduce the photodiode area, so that the photodiode performance is guaranteed.

[0032] The present invention firstly provides a method for forming an image sensor, including: providing a semiconductor substrate with a first conductivity type, the semiconductor substrate includes a first pixel unit area and a second pixel unit area, and each pixel unit area has a photoelectric Diode region; forming a device isolation layer between the photodiode region of the first pixel unit region and the photodiode region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com