Explosion-proof battery

A battery and battery cartridge technology, applied to battery pack parts, circuits, electrical components, etc., can solve the problems of not being able to install explosion-proof devices, achieve the effects of reducing the difficulty of sealing, solving the limitation of strength, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

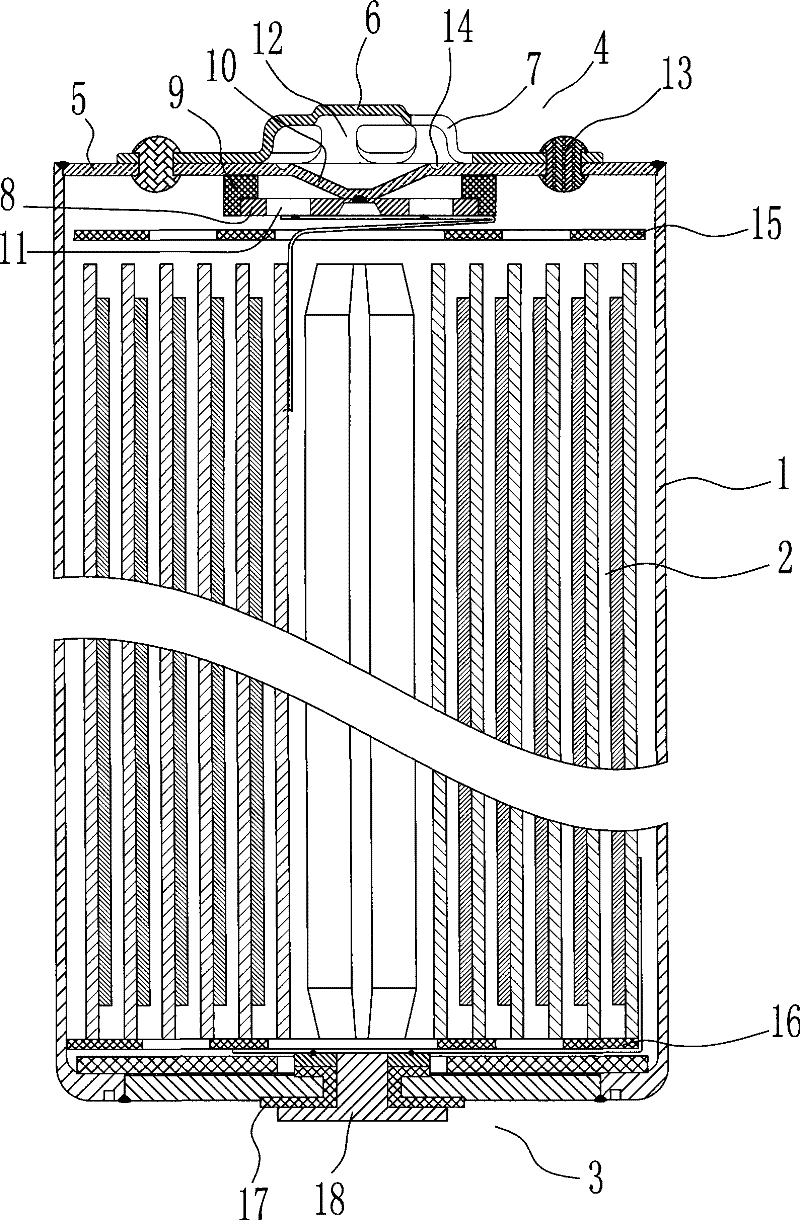

[0026] figure 1 The specific structure of an explosion-proof battery is shown, including: a battery cylinder 1, a battery unit 2 accommodated in the battery cylinder 1, a first cover assembly 3 and a second cover for leading out electrodes and sealing the battery cylinder 1 Component 4; the pole 18 of the first cover component 3 communicates with the negative pole of the battery unit 2, and is insulated from the battery cylinder 1 through an insulating gasket 17; the second cover component 4 that communicates with the positive pole of the battery unit 2 includes a substrate 5. A protective cover 6 with an air hole 7, a lead cover 8 and an insulator 9. The substrate 5 is directly welded to the battery cylinder 1 to seal it. The center of the substrate 5 forms a thin-walled explosion-proof membrane 10; the explosion-proof membrane 10 is umbrella-shaped It protrudes toward the inside of the battery, and the protruding part touches the center of the lead cover 8 and is electricall...

Embodiment 2

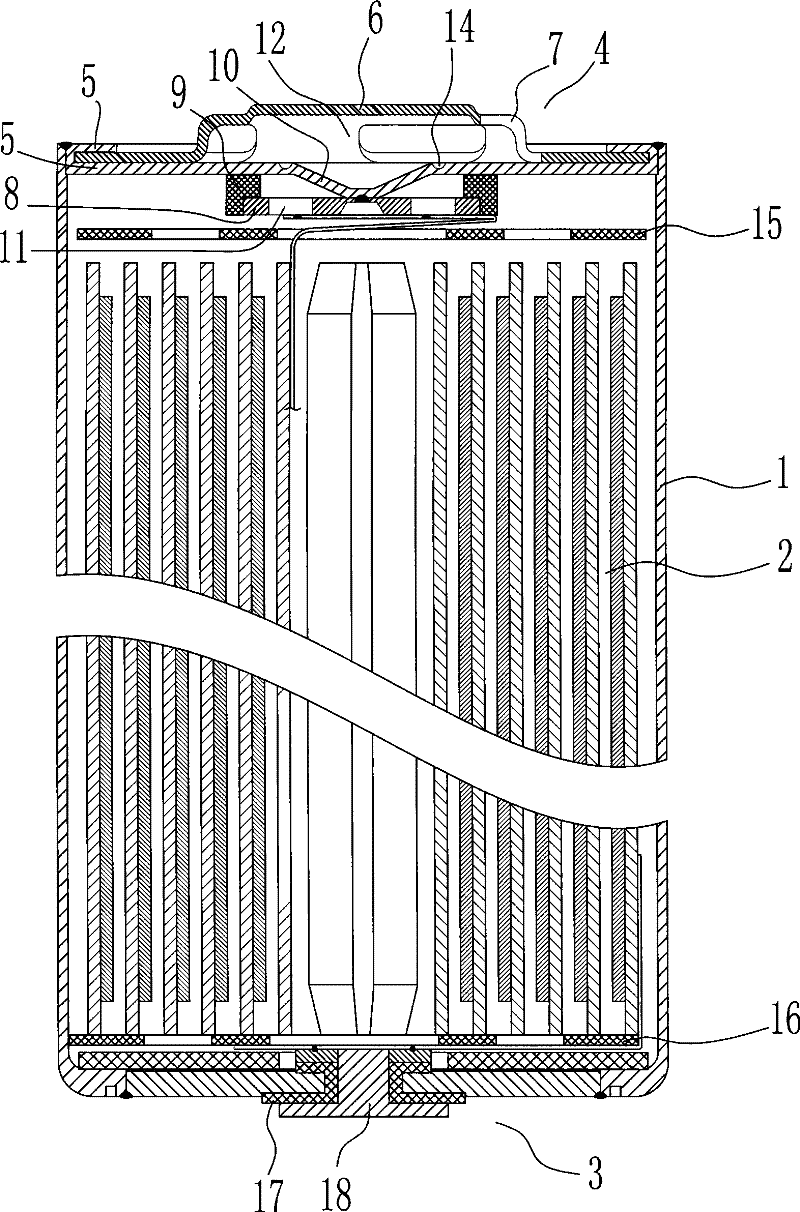

[0028] figure 2 The specific structure of another explosion-proof battery is shown, including the battery cylinder 1, the battery unit 2 accommodated in the battery cylinder 1, the first cover assembly 3 and the second cover assembly used to lead out the electrodes and seal the cylinder 1 4. The pole 18 of the first cover assembly 3 communicates with the negative pole of the battery unit 2 and is insulated from the battery cylinder 1 through the insulating gasket 17; the second cover assembly 4 communicated with the positive pole of the battery unit 2 includes a substrate 5 , a protective cover 6 with an air hole 7, a lead cover 8 and an insulator 9, the substrate 5 is directly welded to the battery cylinder 1 to seal it, wherein a thin-walled explosion-proof membrane 10 is formed at the center of the substrate 5; the explosion-proof membrane 10 is umbrella-shaped to The interior of the battery is raised, and the raised part is against the center of the lead cover 8, and is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com