A mems capacitor microphone, a method of manufacturing a mems capacitor microphone, a stack of foils, an electronic device and use of the electronic device

A technology of electronic equipment, microphone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

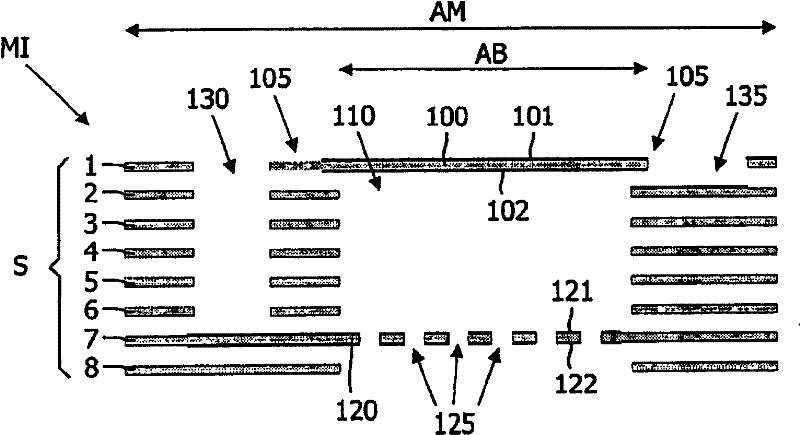

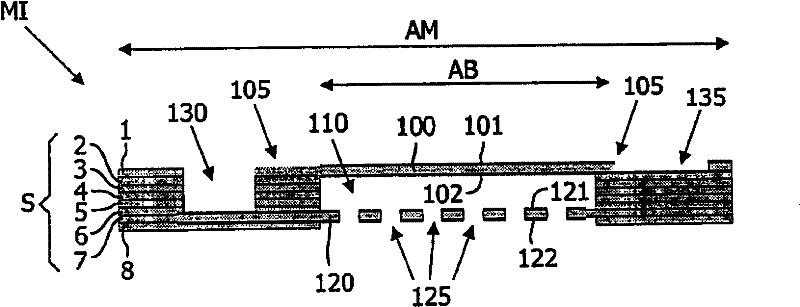

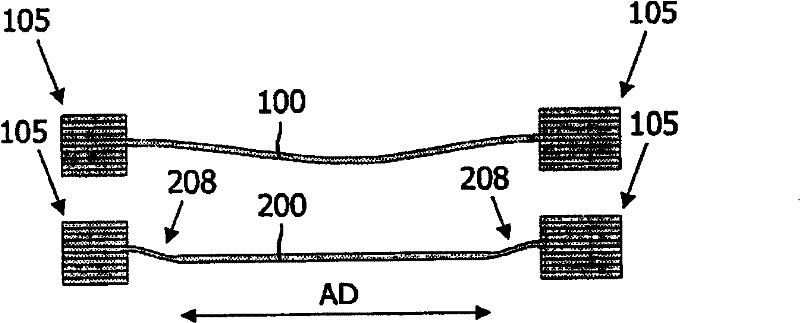

[0058] Hereinafter, a detailed description of the present invention will be given. As previously described, the present invention relates to a method of manufacturing a MEMS capacitor microphone as well as to such a MEMS capacitor microphone itself. The method of fabricating a MEMS capacitor microphone consists of several sub-steps:

[0059] - applying a conductive layer to at least one face of the foil (so both faces are also possible, and in some cases even preferred);

[0060] - Pretreatment of the foil;

[0061] - stacking foils, thus forming a MEMS capacitor microphone;

[0062] - adhesive foil; and

[0063] - Separation of the MEMS capacitor microphone from the foil stack.

[0064] The pretreatment of the foil consists of selected following steps:

[0065] - Leave the conductive layer and foil intact;

[0066] - remove the conductive layer to expose the foil;

[0067] - removing the conductive layer and part of the foil so that a thinner foil remains; or

[0068]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com