Process for producing sheath-core staple fibre with a three-dimensional crimp, and corresponding sheath-core staple fibre

A technology of three-dimensional crimping and short fibers, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve disadvantages and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

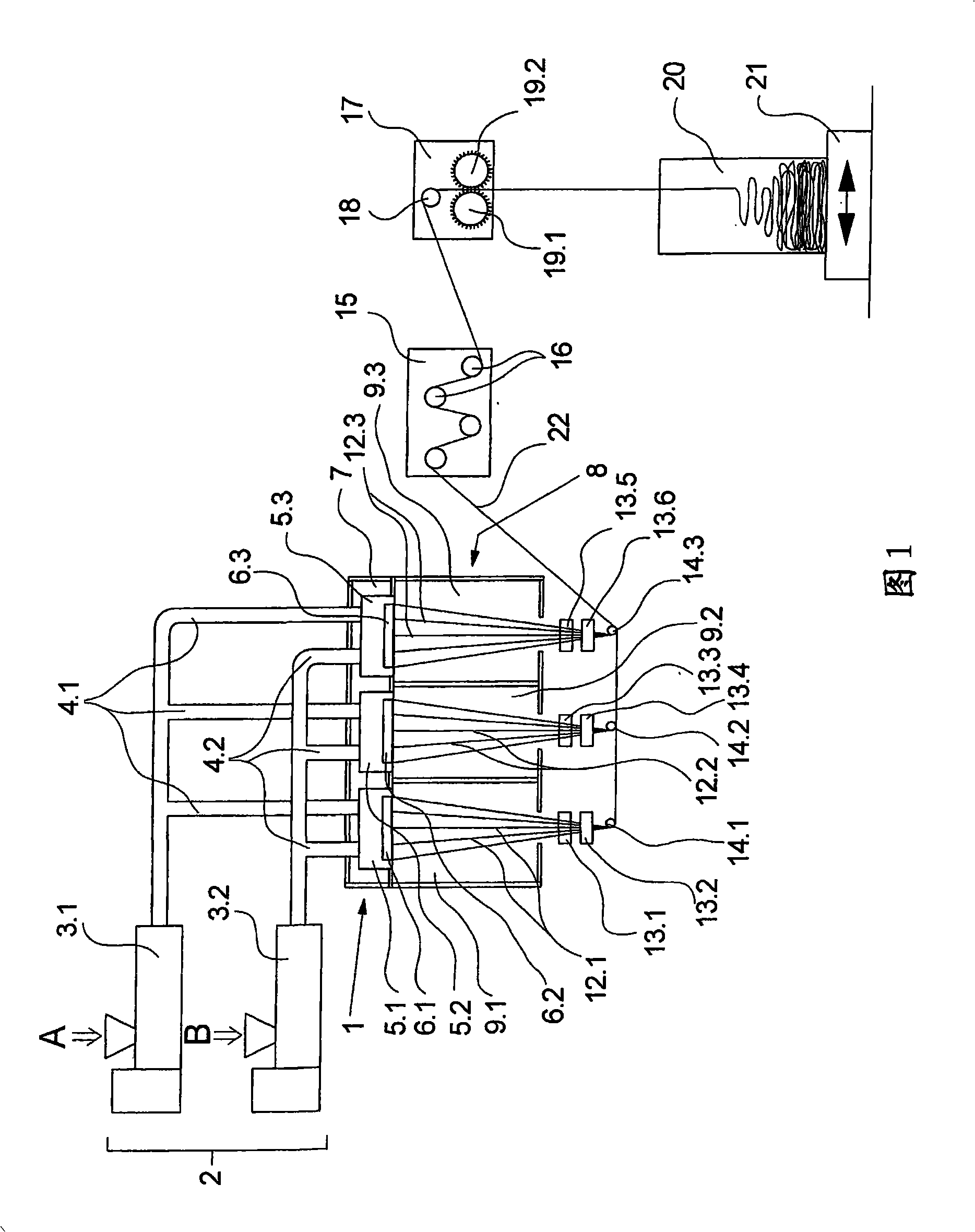

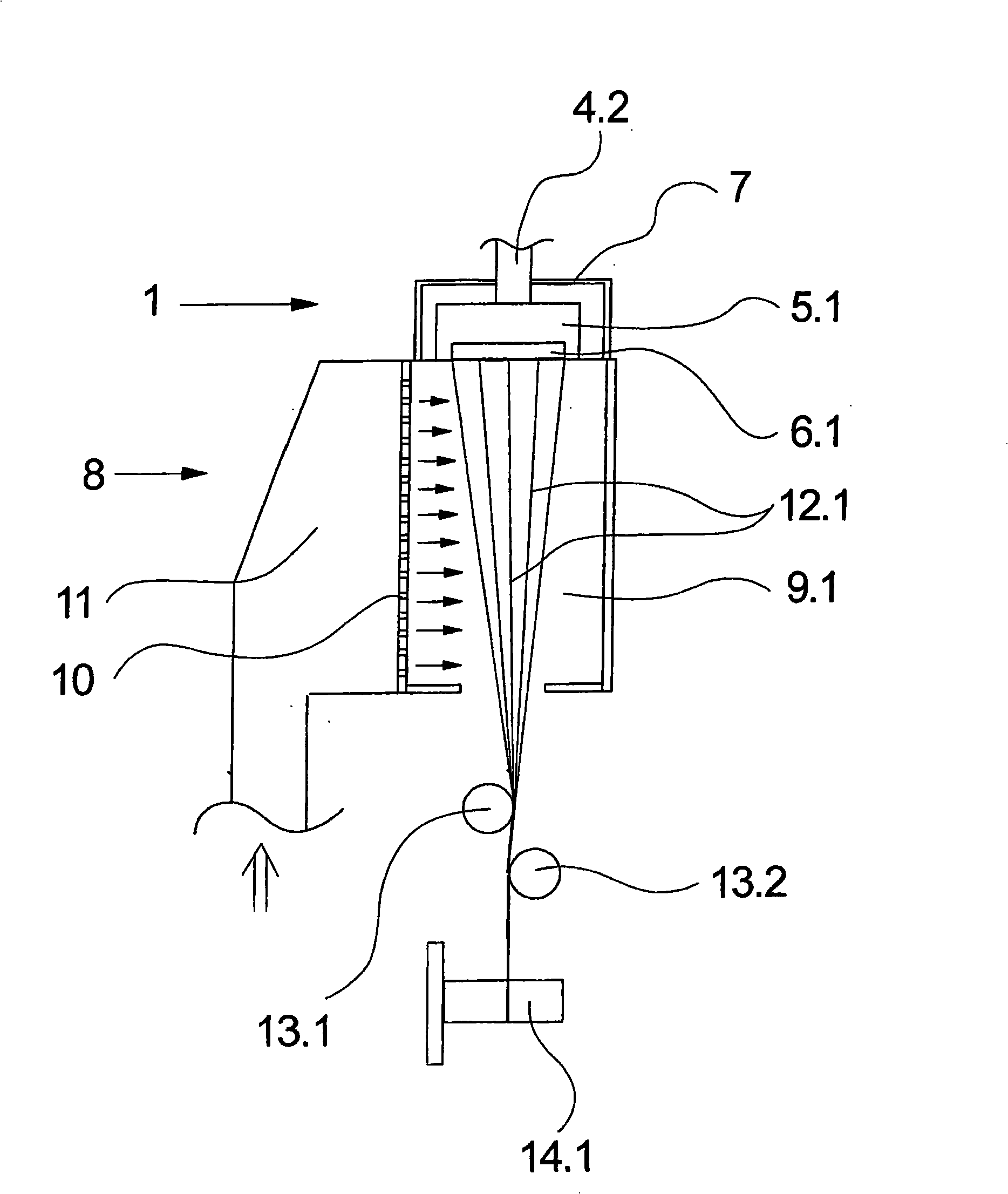

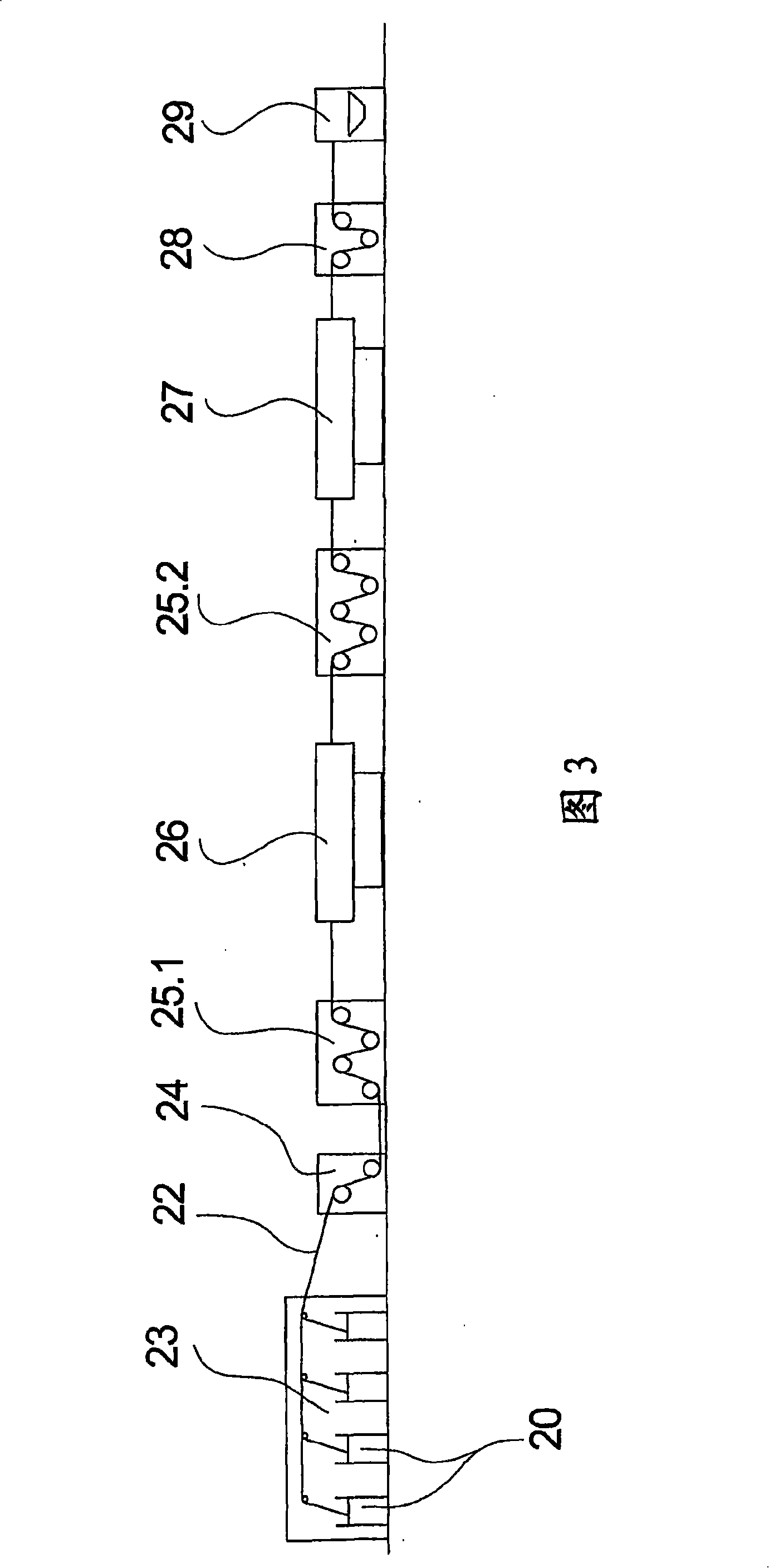

[0035] The device components shown in FIGS. 1 and 3 form an exemplary embodiment of a device for carrying out the method according to the invention. This staple fiber manufacturing apparatus has a feature of intermediate storage / temporary storage of fibers extruded by melt spinning before multi-stage processing. As a result, different production speeds and different material flows (volumes) can be realized during melt-spinning of fibers and during multistage processing of fibers and can be optimized for the corresponding process section. In the first stage of the production process, a plurality of sheath-core fibers are extruded and deposited as so-called fiber bundles in cans for intermediate storage.

[0036] An embodiment of such a melt spinning apparatus is shown schematically in several views in FIGS. 1 and 2 . Figure 1 shows the melt spinning equipment in side view, in figure 2 The melt-spinning apparatus is shown in cross-sectional view in . The following description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com