Fluorophosphate coated lithium titanate composite material as well as preparation method and application thereof

A technology of coating lithium titanate with fluorophosphate and lithium titanate with phosphate, which is applied in the field of lithium-ion battery anode materials, can solve problems such as gas production, unfavorable industrial production, and cumbersome operation, and achieve the coating layer The effect of controllable thickness, improved conductivity, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) After mixing lithium acetate and ethyl titanate in molar amounts Li:Ti=1:1.25 evenly, raise it from room temperature to 700°C at 1°C / min in nitrogen, keep it warm for 12 hours, and then heat it at 5°C / min Cool rapidly to room temperature to obtain lithium titanate.

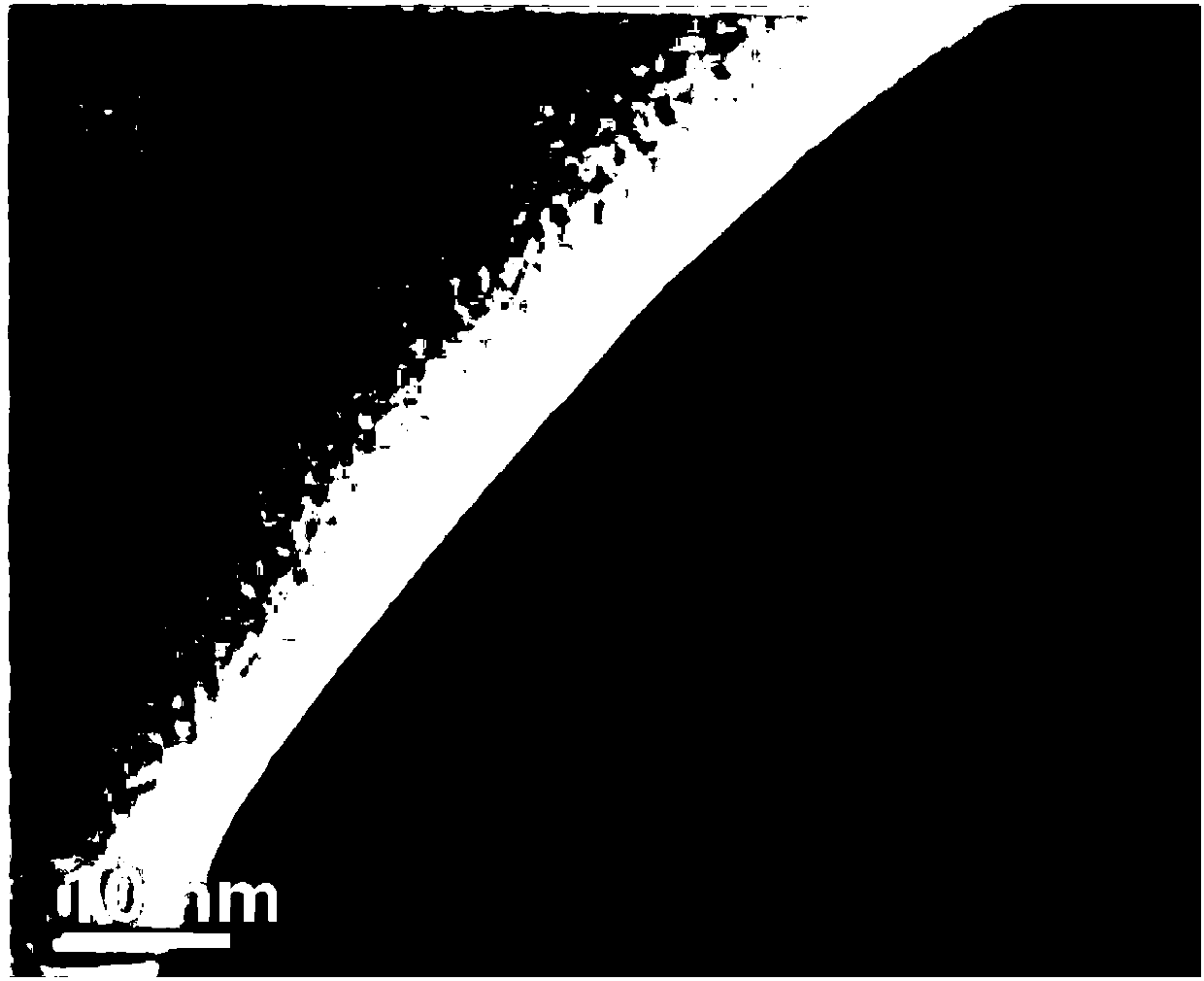

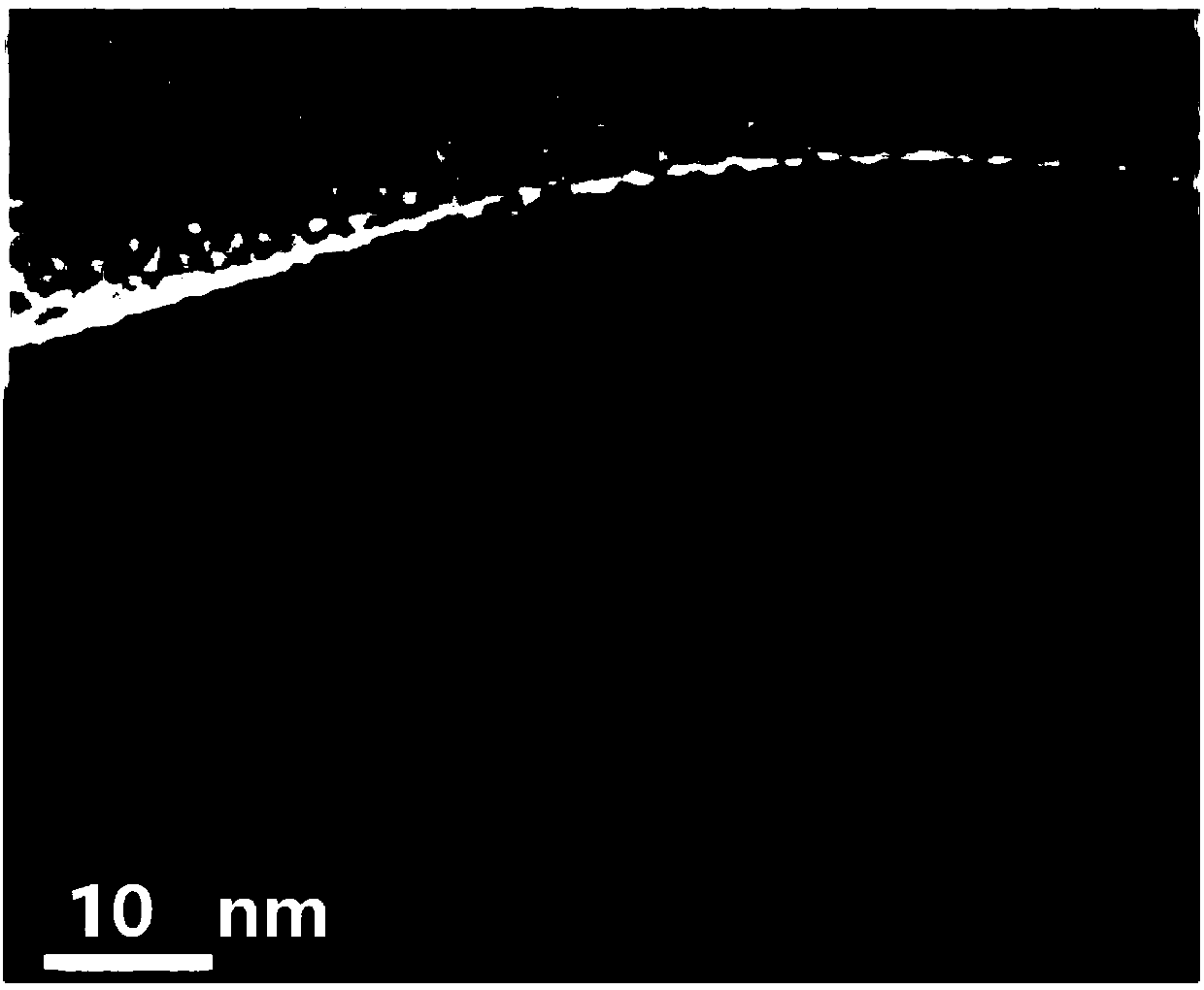

[0056] (2) Dissolve lithium titanate in deionized water, stir evenly, add 0.01wt% (based on the mass of lithium titanate as 100wt%) lithium aluminum fluorophosphate, and dry at 150°C for 2 minutes on a spray dryer to form aluminum fluorophosphate Lithium is coated on the surface of lithium titanate particles, and then put into a reaction vessel, heated to 400°C in a microwave sintering furnace and kept for 30 minutes, then cooled to room temperature at 5°C / min, then removed from the reaction vessel, and the lithium aluminum fluorophosphate package inside is taken out Coated lithium titanate composite material.

[0057] test:

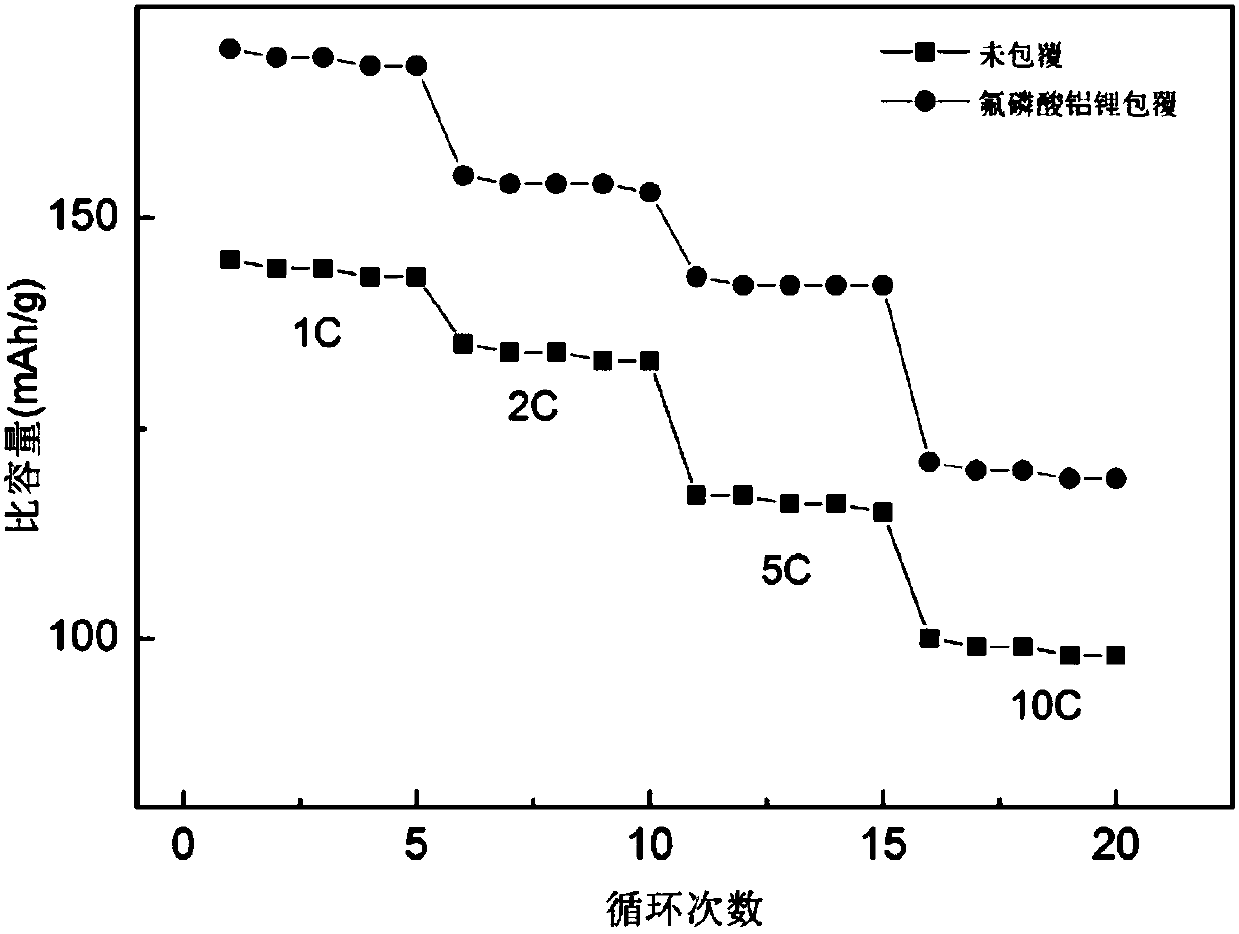

[0058] Using the lithium titanate composite material coated with lithium al...

Embodiment 2

[0065] (1) After mixing lithium carbonate and titanium dioxide in molar amounts Li:Ti=1:1.25 evenly, rise from room temperature to 800°C at 3°C / min in hydrogen, keep warm for 10 hours, and then rapidly cool at 10°C / min to Lithium titanate was obtained at room temperature.

[0066] (2) Dissolve lithium titanate in ethanol, stir evenly, add 0.05wt% (based on the mass of lithium titanate as 100wt%) nickel lithium fluorophosphate, dry at 150°C for 1min on a spray dryer to form lithium nickel fluorophosphate Coated on the surface of lithium titanate particles, then put into a reaction vessel, heated to 600°C in a microwave sintering furnace and kept for 20 minutes, then cooled to room temperature at 10°C / min, then removed from the reaction vessel, and took out the lithium nickel fluorophosphate coating inside Lithium titanate composite material.

[0067] test:

[0068] The nickel-lithium fluorophosphate-coated lithium titanate composite material of this example was used as the ne...

Embodiment 3

[0070] (1) After mixing lithium hydroxide and tetrabutyl titanate in a molar amount Li:Ti=1:1.25 evenly, heat it from room temperature to 700°C at 2°C / min in carbon dioxide, keep it warm for 8 hours, and then heat it at 5°C / min is rapidly cooled to room temperature to obtain lithium titanate.

[0071] (2) Dissolve lithium titanate in ethanol, stir evenly, add 0.10wt% (based on the mass of lithium titanate as 100wt%) lithium manganese fluorophosphate, and dry at 160°C for 1 min on a spray dryer to form lithium manganese fluorophosphate Coated on the surface of lithium titanate particles, then put into a reaction container, heated to 500°C in a microwave sintering furnace and kept for 30 minutes, then cooled to room temperature at 10°C / min, then removed from the reaction container, and took out the lithium manganese fluorophosphate coating inside Lithium titanate composite material.

[0072] The lithium manganese phosphate-coated lithium titanate composite material of this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com